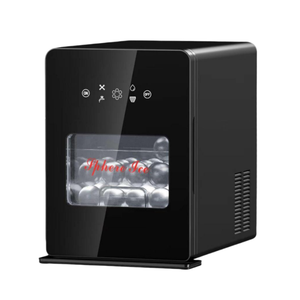

Ice Cube Machine Countertop

1/15

1/15

1/13

1/13

1/10

1/10

1/2

1/2

CN

CN

1/21

1/21

1/18

1/18

1/16

1/16

1/20

1/20

About ice cube machine countertop

Where to Find Countertop Ice Cube Machine Suppliers?

China remains the dominant manufacturing hub for countertop ice cube machines, with key supplier clusters concentrated in Guangdong, Guangxi, and Jiangsu provinces. These regions host vertically integrated production ecosystems that combine compact appliance engineering, plastic molding, refrigeration component sourcing, and final assembly under one supply chain. Guangdong—particularly Shenzhen and Foshan—leads in consumer-grade appliance innovation, offering rapid prototyping and high-volume output for portable and smart-enabled models. Meanwhile, Jiangsu and Guangxi specialize in commercial-duty units, leveraging proximity to compressor and heat exchanger suppliers to reduce material costs by 10–18% compared to offshore alternatives.

The industrial clusters support scalable production through co-located component manufacturers, enabling lead times as short as 25–35 days for standard orders. Facilities typically maintain in-house capabilities for injection molding, sheet metal fabrication, and electronic control board integration, reducing dependency on external vendors. Buyers benefit from localized logistics networks, with major ports like Nansha and Qingdao facilitating efficient containerized shipping. The region’s mature supply base also allows flexibility in order volume, supporting both low MOQ sampling (as low as 1 piece) and bulk procurement exceeding 1,000 units per month.

How to Choose Countertop Ice Cube Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional criteria:

Quality Assurance & Compliance

Verify adherence to international safety and performance standards such as CE, RoHS, and UL where applicable. While not all suppliers hold ISO 9001 certification, prioritize those with documented quality control processes—including incoming material inspection, in-line testing, and final product validation. Confirm compliance documentation for electrical components and refrigerants, especially for shipments to EU and North American markets.

Production Capacity & Scalability

Assess infrastructure indicators such as facility size, monthly output capacity, and workforce composition. Key benchmarks include:

- Minimum factory area of 2,000m² for stable mass production

- In-house R&D or engineering teams capable of supporting design improvements

- Automation level in assembly lines affecting consistency and throughput

Cross-reference on-time delivery rates (target ≥97%) and reorder frequency to gauge reliability and customer satisfaction.

Customization & Transaction Security

For branded or private-label orders, confirm available customization options: color finishes, logo imprinting, packaging design, and voltage configuration (110V/220V). Suppliers with dedicated OEM/ODM experience typically offer greater flexibility. Utilize secure payment mechanisms such as trade assurance or escrow services, and request sample units before full-scale ordering to validate build quality, noise levels, and ice production rate.

What Are the Best Countertop Ice Cube Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Whalfly Tek Co., Ltd. | Guangdong, CN | Ice Makers, Handheld Vacuums, Fans | US $9,000+ | 100% | ≤1h | <15% | 1 piece | $39.90–159.99 |

| Guangxi Aistan Kitchen Equipment Manufacturing Company Limited | Guangxi, CN | Commercial Ice Makers, Under-Counter Units | US $30,000+ | 95% | ≤4h | <15% | 1–5 pieces | $113.60–192.24 |

| Xuzhou Yingse Houseware Co., Ltd. | Jiangsu, CN | Portable Ice Makers, Humidifiers, Fryers | US $40,000+ | 100% | ≤1h | <15% | 1–16 sets | $36–198 |

| Shenzhen Aurotech Technology Co., Ltd. | Shenzhen, CN | Mini Ice Makers, Portable Fans | US $130,000+ | 100% | ≤2h | 15% | 100–300 pieces | $34.50–110 |

| Shenzhen Jiuxiang Electric Appliance Co., Ltd. | Shenzhen, CN | Compact Ice Makers, Home Appliances | US $120,000+ | 97% | ≤4h | <15% | 1–100 pieces | $40–54 |

Performance Analysis

Suppliers like Whalfly Tek and Xuzhou Yingse demonstrate strong responsiveness (≤1h average reply time) and perfect on-time delivery records, making them suitable for time-sensitive procurement. Shenzhen-based companies dominate high-volume export activity, with Aurotech and Jiuxiang reporting online revenues exceeding US $120,000, indicating robust market penetration. However, lower reorder rates (<15%) suggest most buyers are engaged in trial or project-based purchasing rather than long-term contracts. For cost-sensitive buyers, Shenzhen Aurotech offers some of the lowest unit prices ($34.50 at MOQ 300), while Guangxi Aistan targets commercial clients with higher-capacity models. Prioritize suppliers offering sample availability and clear MOQ scaling terms to mitigate risk during initial engagement.

FAQs

What is the typical minimum order quantity for countertop ice cube machines?

MOQ varies significantly by supplier and model. Some offer single-unit sampling (e.g., 1 piece), while others require 100–300 units for entry-level pricing. Commercial or customized models may have higher thresholds, typically 5–10 units for bulk configurations.

How long does production and shipping take?

Manufacturing lead time ranges from 25–40 days post-deposit, depending on order complexity and customization. Air freight delivery takes 5–10 days for samples; sea freight for full containers requires 25–35 days to major global ports.

Can suppliers customize ice machine specifications?

Yes, many suppliers support OEM/ODM modifications including housing color, brand labeling, voltage settings, and ice basket capacity. Confirmation of tooling feasibility and additional costs should be obtained prior to order placement.

Do countertop ice makers meet international safety standards?

Compliance varies. Leading suppliers provide CE and RoHS certifications upon request. Buyers must explicitly verify test reports for electrical insulation, leakage current, and refrigerant handling to ensure regulatory alignment in target markets.

Is sample testing recommended before bulk ordering?

Strongly advised. Request functional samples to evaluate ice production speed, noise level (typically 40–50 dB), water efficiency, and durability over continuous operation. Sample costs may apply but are often credited toward future orders.