Ice Cube Machine Makro

1/21

1/21

1/25

1/25

1/10

1/10

1/28

1/28

1/12

1/12

1/8

1/8

CN

CN

1/17

1/17

1/13

1/13

1/28

1/28

1/19

1/19

1/27

1/27

1/29

1/29

1/22

1/22

1/11

1/11

1/41

1/41

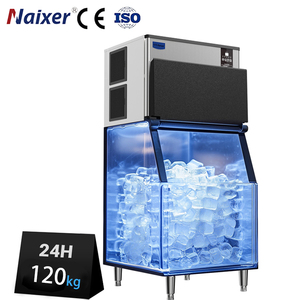

About ice cube machine makro

Where to Find Ice Cube Machine Suppliers?

China remains the global epicenter for commercial and industrial ice cube machine manufacturing, with key production clusters in Guangdong, Henan, and Shanghai. These regions host vertically integrated supply chains specializing in refrigeration systems, stainless steel fabrication, and automated control units—critical components for reliable ice production. Guangdong leads in high-capacity industrial models, leveraging proximity to Dongguan’s electronics hubs for advanced cooling controls. Henan's machinery corridor supports cost-efficient production of mid-range commercial units, while Shanghai suppliers focus on precision engineering for compact, energy-efficient designs tailored to foodservice operations.

The concentration of component manufacturers within 50km radii enables rapid prototyping and assembly, reducing lead times by up to 25% compared to decentralized production models. Buyers benefit from scalable output, with facilities capable of producing 1–2,000kg/day units across batch and continuous-production lines. Localized access to cold-rolled steel, evaporator coils, and compressors ensures consistent material quality and 15–25% lower unit costs than Western equivalents. Standard delivery windows range from 20–40 days depending on customization level and order volume.

How to Choose Ice Cube Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance standards, including CE marking for European markets and UL/CSA alignment for North America. Request documentation on compressor efficiency (e.g., Copeland or Danfoss certification), refrigerant type (R404A, R134a compliance), and IP ratings for moisture resistance. For food-grade applications, confirm use of 304 or 316L stainless steel in contact surfaces and NSF-certified components.

Production Capability Audits

Assess core infrastructure metrics:

- Minimum factory area of 3,000m² for sustained output

- In-house refrigeration system assembly and leak-testing protocols

- CNC bending and TIG welding capabilities for metal fabrication

Cross-reference on-time delivery rates (target ≥98%) and response times (≤2 hours) as indicators of operational maturity.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial procurement. Prioritize suppliers with transparent online revenue histories and reorder rates above 20%, indicating customer satisfaction. Conduct sample testing to validate ice clarity, cycle time, and bin capacity before scaling orders. Confirm packaging integrity for long-distance shipping, especially for condenser-sensitive units.

What Are the Best Ice Cube Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Luohe Ejin Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $150,000+ | 98% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic | 1 set |

| Shanghai Bokni Refrigeration Equipment Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $780,000+ | 98% | ≤4h | 23% | Capacity, bin capacity, cooling type, compressor, plug, model, material, size, logo, packaging, label, graphic | 1 piece |

| Guangdong Taihe Refrigeration Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $50,000+ | 100% | ≤2h | 37% | Capacity, refrigeration type, cooled type, design, single phase, size, logo, graphic, color, shape, packaging, label | 1 set |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $460,000+ | 98% | ≤2h | 32% | Color, material, size, logo, packaging, label, graphic | 1 set |

| Kaifeng Rainbow Machinery Co., Ltd. | Henan, CN | Not Specified | US $10,000+ | 95% | ≤2h | <15% | Limited public data | 1 set |

Performance Analysis

Guangdong Taihe stands out with a 100% on-time delivery rate and robust customization across refrigeration types and electrical configurations, making it ideal for buyers requiring region-specific voltage or cooling solutions. Shanghai Bokni demonstrates strong market penetration (reorder rate: 23%) and extensive configurability, particularly in compressor and plug variants, supporting global deployment. Luohe Ejin and Zhengzhou Yize offer balanced performance with sub-2-hour response times and moderate customization, suitable for standard commercial deployments. Kaifeng Rainbow provides entry-level pricing but lacks verified specialization in refrigeration, suggesting suitability only for low-capacity or auxiliary applications.

FAQs

How to verify ice cube machine supplier reliability?

Validate certifications (CE, ISO 9001) through issuing bodies and request test reports on compressor endurance, ice yield consistency, and water consumption per cycle. Analyze customer feedback focusing on after-sales service, spare parts availability, and field failure rates. Use video audits to inspect production lines and quality control checkpoints.

What is the typical sampling timeline?

Standard samples are produced within 10–18 days. Units with custom voltage, bin modifications, or refrigerant specifications may require 25–35 days. Air freight adds 5–12 days for international delivery, depending on destination.

Can suppliers ship ice cube machines worldwide?

Yes, established manufacturers support global logistics via FOB or CIF terms. Confirm compatibility with local electrical grids (single/three-phase) and refrigerant import regulations. Sea freight is recommended for bulk shipments due to equipment weight and sensitivity to temperature fluctuations.

Do manufacturers provide free samples?

Sample fees are typically charged but partially or fully refunded upon placement of a full order. Free samples are generally offered only for repeat customers or orders exceeding 5 units.

How to initiate customization requests?

Submit detailed specifications including daily ice output (kg), cube size (standard, half, crescent), cooling method (air/water-cooled), power supply (voltage, phase), and bin integration requirements. Leading suppliers provide technical drawings within 72 hours and can deliver prototypes within 4 weeks.