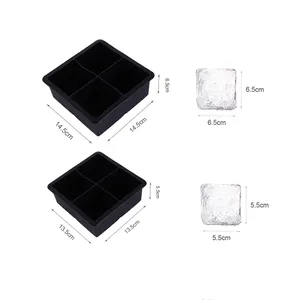

Ice Cube Trays Large Square

Top sponsor listing

Top sponsor listing

1/27

1/27

1/9

1/9

1/2

1/2

CN

CN

1/22

1/22

1/29

1/29

1/23

1/23

1/33

1/33

About ice cube trays large square

Where to Find Large Square Ice Cube Tray Suppliers?

China remains the central hub for kitchenware manufacturing, with specialized clusters in Zhejiang, Guangdong, and Yiwu producing high volumes of large square ice cube trays. These regions host vertically integrated supply chains that support rapid prototyping and mass production of silicone and plastic-based molds. The concentration of material suppliers, injection molding facilities, and packaging specialists within 50km radii enables streamlined operations, reducing lead times and logistics costs.

Zhejiang excels in food-grade silicone processing, offering advanced vulcanization and compression molding capabilities essential for durable, non-stick ice trays. Guangdong’s Shenzhen region specializes in BPA-free plastic injection molding, leveraging automated production lines to achieve monthly outputs exceeding 500,000 units per facility. Yiwu serves as a commodity export center, aggregating smaller manufacturers focused on cost-competitive options for global distributors. Buyers benefit from localized ecosystems that ensure faster fulfillment (average 25–35 days for bulk orders), 15–25% lower unit costs compared to Western producers, and flexibility in both customization and order volume.

How to Choose Large Square Ice Cube Tray Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Material & Safety Compliance

Verify use of food-safe materials compliant with FDA, LFGB, or EU Regulation (EC) No 1935/2004. For silicone products, confirm Shore A hardness ratings between 40–60 for optimal flexibility and durability. Demand test reports for BPA, phthalates, and heavy metals. CE or RoHS markings indicate adherence to international safety standards, critical for retail distribution in Europe and North America.

Production and Customization Capacity

Assess infrastructure through key indicators:

- Minimum factory area of 2,000m² for stable output

- In-house mold-making and design teams for custom cavity configurations (e.g., 4–28 cells)

- Capability in color matching (Pantone standards), logo embossing, private labeling, and retail-ready packaging

Cross-reference online revenue metrics and reorder rates to validate scalability and customer retention. Prioritize suppliers with response times under 5 hours and on-time delivery performance above 95%.

Order Terms and Risk Mitigation

Evaluate minimum order quantities (MOQs), which typically range from 100 to 1,000 pieces depending on material and complexity. Negotiate tiered pricing based on volume commitments. Utilize secure payment structures such as escrow or letter of credit for initial transactions. Request physical or digital samples to verify product dimensions, release performance, and structural integrity before full-scale procurement.

What Are the Best Large Square Ice Cube Tray Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Yangxing Enterprises Limited | Fujian, CN | Custom Manufacturer | Utensils, Cake Tools, Ice Cream Tools, Chopping Blocks | 95% | ≤5h | $580,000+ | <15% | Color, size, logo, mold, packaging, graphic |

| Yongkang E Spring Industry & Trade Co., Ltd. | Zhejiang, CN | - | Ice Cream Tools, Pet Bowls, Lunch Boxes, Kids Dining | 100% | ≤3h | $870,000+ | <15% | Limited (standard models) |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Guangdong, CN | Custom Manufacturer | Silicone Molds, Ice Ball Makers, Food Storage | 97% | ≤4h | $220,000+ | 19% | Full: color, shape, logo, packaging, private label, material |

| Ningbo Dazen Technology Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | Silicone Kitchenware, Reusable Molds | 100% | ≤3h | $120,000+ | <15% | Color, size, logo, packaging, graphic |

| Yiwu Ziming Commodity Co., Ltd. | Yiwu, CN | - | Ice Cream Tools, Household Sundries, Colanders | 100% | ≤3h | $2,000+ | <15% | Logo, size, packaging (low MOQ options) |

Performance Analysis

Yongkang E Spring leads in reliability with 100% on-time delivery and sub-3-hour response times, supported by strong revenue volume, making it ideal for consistent restocking. Shenzhen Benhaida offers the most comprehensive customization suite—including Pantone color matching, patented packaging, and private labeling—despite a higher reorder rate (19%), indicating active client acquisition. Yangxing Enterprises provides dedicated manufacturing capabilities with extensive mold and design flexibility, suitable for branded product development. Ningbo Dazen and Yiwu Ziming serve niche markets with flexible MOQs, though lower revenue figures suggest smaller production scales. Buyers seeking premium silicone variants should prioritize suppliers with documented material testing and in-house R&D teams.

FAQs

How to verify ice cube tray material safety?

Request compliance documentation for FDA 21 CFR, EU 1935/2004, or LFGB standards. Confirm third-party lab reports for silicone purity (VMQ grade) or BPA-free thermoplastics. Conduct extractable testing under extreme temperatures (-20°C to 100°C) to assess leaching risks.

What is the typical lead time for bulk orders?

Standard orders require 20–30 days from confirmation, including production and pre-shipment inspection. Custom tooling adds 7–14 days for mold development. Air freight delivers samples in 5–7 days; sea freight takes 25–40 days depending on destination.

Can suppliers accommodate private label branding?

Yes, most verified manufacturers offer full private labeling, including custom logos, color schemes, retail boxes, and barcode integration. Minimum order thresholds typically start at 1,000 units for full branding packages.

What are common MOQs for large square ice trays?

MOQs vary by material and customization level: silicone trays average 500–1,000 pieces, while basic plastic models may allow as few as 100 units. Sample orders of 3–10 pieces are generally available at higher per-unit prices.

How to initiate a customization request?

Submit detailed specifications including cavity dimensions (e.g., 2-inch cubes), cell count (4–28), material type (silicone/plastic), color (Pantone code), logo placement, and packaging format. Reputable suppliers respond with design proofs within 48 hours and deliver functional samples in 7–10 days.