Ice Machine Maker To Store Ice

Top sponsor listing

Top sponsor listing

1/19

1/19

0

0

1/25

1/25

1/3

1/3

1/18

1/18

CN

CN

1/25

1/25

0

0

1/3

1/3

1/3

1/3

CN

CN

1/30

1/30

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/19

1/19

1/3

1/3

About ice machine maker to store ice

Where to Find Ice Machine Maker Suppliers for Storage Applications?

China remains the global epicenter for industrial and commercial ice machine manufacturing, with key production clusters in Jiangsu, Shanghai, and Guangdong provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, refrigeration system assembly, and stainless steel fabrication—enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers. Jiangsu and Shanghai specialize in high-capacity industrial systems (1–5 ton/day output), leveraging proximity to Danfoss, Siemens PLC, and Bitzer compressor suppliers for consistent component availability.

Guangdong-based manufacturers focus on compact commercial units for food service and retail, benefiting from dense networks of sheet metal, molding, and control panel suppliers within a 30km radius. This regional clustering reduces lead times by up to 40%, with standard orders typically fulfilled in 25–35 days. Buyers gain access to scalable production lines capable of delivering units ranging from 55kg/day countertop models to 1,000kg+ daily flake ice systems with integrated storage bins.

How to Choose Ice Machine Maker Suppliers for Reliable Ice Storage?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international standards such as CE, RoHS, and ISO 9001 for quality management. For export markets, confirm compatibility with local electrical specifications (e.g., 3-phase 380V/50Hz or single-phase 110V/60Hz). Assess refrigeration method expertise—air-cooled, water-cooled, or containerized designs—with preference given to suppliers using original compressors (e.g., Danfoss, Emerson) and food-grade 304 stainless steel for hygienic ice storage.

Production and Customization Capacity

Evaluate core capabilities through these benchmarks:

- Minimum facility size of 3,000m² indicating scalable production capacity

- In-house engineering teams supporting OEM/ODM customization (e.g., bin size, logo, color, insulation thickness)

- Proven experience with thermal insulation design and refrigeration cycle optimization

Cross-reference product listings with on-time delivery rates exceeding 95% and reorder rates below 25% to assess customer retention and fulfillment reliability.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services until post-arrival inspection. Request sample units to validate ice clarity, production rate, and storage bin temperature stability. Prioritize suppliers offering detailed technical documentation, including wiring diagrams, cooling method specifications, and compressor type details. Confirm packaging includes moisture-resistant export crates suitable for maritime transport.

What Are the Leading Ice Machine Maker Suppliers with Storage Integration?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

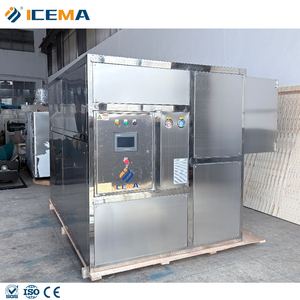

| Shanghai Icema Refrigeration Technology Co., Ltd. | Shanghai, CN | Industrial Ice Cube Makers, Tube Ice Machines, Cold Rooms | US $1.1M+ | 95% | ≤2h | 24% | Full system customization: phase, cooling method, bin size, PLC controls, solar compatibility | 410–7,800 USD; 100kg–3-ton/day capacity |

| Nantong Bolang Energy Saving Technology Co., Ltd. | Jiangsu, CN | Commercial Ice Machines, Slurry Ice Systems, Chewing Ice Units | US $160K+ | 98% | ≤2h | <15% | Color, material, logo, packaging, label, graphic options available | 139–16,900 USD; 17kg–5-ton/day output |

| Guangzhou Bolt Electric Appliance Co., Ltd. | Guangdong, CN | Flake Ice Makers, Fully Automatic Commercial Units | US $1K+ | 100% | ≤6h | Not available | Limited customization; primarily standard configurations | 671–4,513 USD; 500kg–2-ton/day systems |

| Jatton Trading Co., Ltd. | Guangdong, CN | Cube Ice Makers, Hotel & Restaurant Equipment | US $2K+ | 100% | ≤7h | <15% | Standard models only; no customization reported | 290–1,130 USD; 50–120kg/24h capacity |

Performance Analysis

Shanghai Icema leads in engineering depth, offering full-system customization including solar-compatible and containerized industrial designs. With a 95% on-time delivery rate and proven technical team support, it is best suited for large-scale deployments requiring compliance with EU or North American electrical standards. Nantong Bolang demonstrates strong reliability (98% delivery rate) and offers moderate customization at competitive pricing, making it ideal for buyers seeking branded commercial units with tailored aesthetics and packaging.

Guangzhou Bolt and Jatton Trading deliver smaller-volume commercial machines with perfect on-time records but limited customization. While Guangzhou Bolt offers higher-capacity flake ice systems, its response time exceeds 6 hours—potentially delaying technical clarifications. Jatton serves budget-conscious buyers needing reliable cube ice makers for bars and hotels, though product diversity and engineering support are constrained.

FAQs

How to verify an ice machine maker’s technical reliability?

Request certification documents (CE, ISO 9001), compressor brand specifications, and material test reports for stainless steel components. Conduct video audits of production lines to confirm in-house assembly and quality control checkpoints. Validate claims about daily ice yield under ambient temperature conditions (typically 25–30°C).

What is the typical lead time for custom ice machine orders?

Standard units ship in 20–30 days. Custom configurations involving modified storage bins, dual-compressor setups, or specialized cooling methods require 35–50 days, including testing and packaging preparation.

Can suppliers integrate ice storage bins into the machine design?

Yes, most industrial and commercial models include integrated storage bins with capacities from 20kg to 500kg. Suppliers like Shanghai Icema offer modular bin extensions and insulated hoppers for extended hold times. Confirm bin temperature retention (ideally ≤ -5°C) and anti-bridging mechanisms for continuous dispensing.

Do ice machine suppliers provide free samples?

Samples are typically chargeable, with fees covering 30–50% of unit cost. Full reimbursement may apply upon placement of bulk orders (e.g., 5+ units). Small commercial units (under $500) often have non-refundable sample fees.

What customization options are available for ice machine makers?

Leading suppliers support voltage, plug type, language display, color, logo printing, bin size, and refrigeration method adjustments. Advanced options include Siemens PLC controls, Danfoss valves, solar hybrid operation, and IoT-enabled monitoring systems for remote diagnostics.