Ice Maker That Makes Small Round Ice

CN

CN

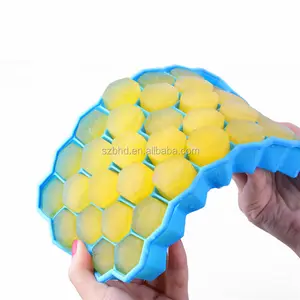

About ice maker that makes small round ice

Where to Source Suppliers for Ice Makers That Make Small Round Ice?

China remains the dominant manufacturing hub for compact ice-making equipment, with key supplier clusters in Guangdong, Jiangsu, and Fujian provinces. These regions host vertically integrated supply chains specializing in small-scale refrigeration units, silicone molds, and plastic ice trays designed for consumer and light commercial use. Shenzhen and Dongguan in Guangdong province are particularly notable for their concentration of hardware-plastic hybrid manufacturers, offering rapid prototyping and low-to-mid volume production runs optimized for export.

The industrial ecosystem supports diverse product types—from electric countertop ice makers producing round pellets to reusable silicone molds forming spherical ice balls. Localized access to injection molding facilities, refrigerant systems, and food-grade plastics enables cost efficiencies of 20–35% compared to Western or Southeast Asian producers. Buyers benefit from short lead times (typically 15–30 days), scalable MOQs ranging from 2 to 500 units, and established compliance with international material safety standards such as LFGB and BPA-free certifications.

How to Evaluate Suppliers for Small Round Ice Makers?

Procurement decisions should be guided by structured assessment criteria focusing on technical capability, quality assurance, and transaction reliability:

Product & Material Compliance

Verify that suppliers use food-safe materials (e.g., BPA-free plastics, LFGB-certified silicone) for all components in contact with water or ice. For electric models, confirm adherence to basic electrical safety standards through available test reports. While formal CE or UL certification is uncommon among smaller suppliers, evidence of compliance testing enhances risk mitigation.

Production Capacity and Flexibility

Assess operational scale based on order fulfillment metrics:

- Minimum factory output capacity of 5,000 units/month for sustained volume orders

- In-house tooling and mold-making capabilities for custom designs

- Support for logo customization, packaging variation, and color specification

Cross-reference online revenue indicators and reorder rates to gauge business stability and customer satisfaction.

Transaction and Quality Assurance

Prioritize suppliers with documented quality control processes and responsive communication. On-time delivery rates exceeding 98%, response times under 5 hours, and participation in third-party trade assurance programs significantly reduce procurement risk. Request product samples to evaluate ice formation consistency, cycle time, and build quality before scaling orders.

What Are the Top Suppliers for Ice Makers That Make Small Round Ice?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Shenzhen Baibanfengxing Technology Co., Ltd. | Fruit & Vegetable Tools, Stainless Steel Tumblers, Ice Cream Tools | US $270,000+ | 98% | ≤5h | <15% | 2–20 pcs | $45–$52 |

| Nantong Bolang Energy Saving Technology Co., Ltd. | Commercial Ice Cube Machines (Customizable) | US $160,000+ | 99% | ≤2h | <15% | 1 pc | $965–$5,078 |

| Dongguan Shiyi Hardware Plastic Technology Co., Ltd. | Pet Bowls, Ice Cream Tools, Drinkware Accessories | US $10,000+ | 100% | ≤4h | <15% | 30–500 pcs | $0.52–$3.20 |

| Xiamen Aulicas Pro-Environment & Tech Co., Ltd. | Ice Makers, Smart Dishwashers, Electric Window Cleaners | US $2,000+ | 100% | ≤2h | 50% | 2–10 pcs | $43–$226 |

| Guangxi Nanning Jiaxin Trading Co., Ltd. | Refrigerator Parts, Car Refrigerators, Ice Makers | US $40,000+ | 80% | ≤7h | <15% | 10 pcs | $39–$75.71 |

Performance Analysis

Shenzhen Baibanfengxing and Xiamen Aulicas offer competitive pricing for residential-grade electric ice makers starting at $43, with Aulicas demonstrating strong buyer retention (50% reorder rate). Nantong Bolang specializes in higher-capacity commercial units, providing customization options for color, labeling, and branding—ideal for B2B clients targeting hospitality markets. Dongguan Shiyi excels in non-electric solutions, supplying low-cost silicone and plastic molds priced under $3.20/unit with MOQs accessible to small retailers. While Guangxi Nanning Jiaxin offers mid-range portable units, its 80% on-time delivery rate indicates potential fulfillment risks compared to top-tier peers.

FAQs

What materials are commonly used in small round ice makers?

Electric models typically combine ABS plastic housings with stainless steel evaporators. Silicone ice ball molds are made from food-grade, flexible silicone compliant with LFGB and FDA standards. Trays and non-electric accessories use BPA-free polypropylene or TPR for durability and safe freezing performance.

What is the typical lead time for bulk orders?

Standard orders are fulfilled within 15–25 days after deposit confirmation. Customized units with logo printing or design modifications may require an additional 7–10 days depending on complexity. Air freight adds 5–7 days for international delivery; sea shipping takes 25–35 days to major global ports.

Can suppliers provide free samples?

Yes, several suppliers—including Dongguan Shiyi and Nantong Bolang—offer free samples for qualified buyers, particularly when followed by a purchase commitment. Sample costs may apply but are often deducted from initial order invoices. Expect 3–7 days for sample dispatch and 5–10 days for international delivery via express courier.

What customization options are available?

Manufacturers support color variation, logo embossing, retail packaging redesign, and label language changes. Some suppliers offer full OEM/ODM services for branded product development, including structural adjustments to tray configurations or machine dimensions. Minimum order thresholds for customization typically start at 500 units.

How do I verify product quality before ordering?

Request product specifications, material compliance documents, and high-resolution images or videos of functional units. Conduct third-party inspections via agencies like SGS or Bureau Veritas if ordering at scale. Always test samples for ice clarity, cycle duration, noise level, and ease of cleaning prior to mass production approval.