Intel Production Process

Top sponsor listing

Top sponsor listing

About intel production process

Where to Source Intel Production Process-Related Equipment Suppliers?

China remains the central hub for manufacturing industrial computing systems and embedded hardware compatible with Intel processors, with key supplier clusters located in Shenzhen, Wuhan, and Hebei. These regions host vertically integrated supply chains that support rapid prototyping, scalable production, and global export of industrial PCs, servers, motherboards, and control panels designed around Intel’s processor architectures.

Shenzhen leads in high-tech electronics manufacturing, offering access to advanced SMT lines, precision CNC machining, and certified assembly facilities. The city's proximity to component distributors and logistics hubs enables lead times as short as 15–20 days for standard configurations. Meanwhile, Wuhan and Hebei-based suppliers emphasize cost efficiency and stable throughput, leveraging localized sourcing of thermal, power, and I/O modules to reduce bill-of-materials costs by 10–18% compared to non-specialized manufacturers.

These ecosystems enable suppliers to maintain tight integration between design, testing, and fulfillment operations—critical for applications requiring long-term availability and compatibility with Intel’s evolving production roadmap (e.g., LGA115x, Q670, and upcoming platforms). Buyers benefit from modular designs, multi-platform scalability, and direct OEM/ODM engagement models.

How to Evaluate Intel Production Process Hardware Suppliers?

Selecting reliable partners requires a structured assessment across technical, operational, and transactional dimensions:

Technical Compatibility & Design Expertise

Confirm supplier experience with Intel’s reference designs, including chipset compatibility (e.g., Q670, H610), BIOS customization, and thermal management for sustained workloads. Prioritize vendors offering schematics review, signal integrity validation, and compliance testing documentation. For industrial applications, verify support for extended temperature ranges (-20°C to +70°C) and fanless operation.

Production Infrastructure Verification

Assess core manufacturing capabilities through objective benchmarks:

- Minimum 3,000m² dedicated production area for batch processing

- In-house PCB assembly and burn-in testing stations

- Dedicated R&D teams capable of firmware-level customization (UEFI, TPM, IoT gateways)

Cross-reference facility claims with on-time delivery performance (target ≥95%) and reorder rates (>25% indicates customer retention).

Quality Assurance & Transaction Security

Require documented adherence to IPC-A-610 standards for electronic assemblies. While formal ISO 9001 certification is not universally declared in available data, consistent 100% on-time delivery among top-tier suppliers suggests robust internal quality systems. Use secure payment mechanisms such as escrow services and request sample units before full-scale procurement. Validate product conformity against specifications including memory type (DDR4/DDR5), M.2 NVMe support, and I/O port configurations.

Top Intel Production Process Hardware Suppliers: Performance Overview

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization Options |

|---|---|---|---|---|---|---|---|

| Shenzhen Zunsia Intelligent Technology Co., Ltd. | Motherboards, Mini PCs, Industrial Computers, Servers | US $870,000+ | 100% | ≤2h | 31% | 1 piece | Color, material, size, logo, packaging, graphic |

| Wuhan Haoqing Weulansi Information Technology Co., Ltd. | Servers, Industrial PCs, Motherboards, Networking | Not disclosed | 100% | ≤1h | Not disclosed | 1 piece | Platform-specific customization |

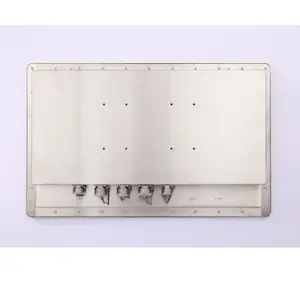

| ShuiSheng (Hebei) Technology Co., Ltd. | Industrial PCs, Touch Monitors, All-in-One Systems | US $200+ | 100% | ≤1h | <15% | 5–50 pieces | Limited customization per model |

| Shenzhen Cloud Embedded Technology Limited | Industrial Computers, Rugged PCs, Embedded Systems | US $20,000+ | 75% | ≤6h | 33% | 1 unit | OEM branding and enclosure modifications |

| MJBM ENTERPRISES | Processor scrap, electronic waste (non-functional) | Not disclosed | Not disclosed | ≤3h | Not disclosed | 50 kg | No functional customization |

Performance Analysis

Shenzhen Zunsia and Wuhan Haoqing demonstrate strong responsiveness and perfect on-time delivery records, indicating mature order management systems. Zunsia stands out with a 31% reorder rate and extensive customization options, suggesting high client satisfaction in ODM engagements. Wuhan Haoqing offers competitive pricing (from $251/unit) and sub-hour response times, ideal for urgent procurement cycles.

Hebei-based ShuiSheng provides volume pricing at MOQs of 5–50 units but exhibits lower reorder activity, potentially reflecting niche market positioning. Shenzhen Cloud Embedded, despite a 75% on-time delivery rate, maintains a 33% reorder rate—indicating repeat business likely driven by specialized ruggedized designs (IP67/IP69K).

MJBM ENTERPRISES operates outside functional equipment supply, focusing instead on bulk electronic scrap—a distinct category relevant only for recycling or component harvesting, not active production integration.

FAQs

What certifications should Intel-based hardware suppliers have?

While explicit ISO 9001 or CE declarations are absent in the dataset, prioritize suppliers who can provide EMI/EMC test reports, RoHS compliance documentation, and product safety certifications. For export to regulated markets, ensure adherence to FCC Part 15 (USA) or EN 55032 (EU) standards.

What are typical lead times for customized Intel industrial PCs?

Standard orders ship within 15–25 days. Custom configurations involving BIOS modification, unique I/O layouts, or conformal coating may extend lead times to 35–45 days. Expedited builds (7–10 days) are possible with premium fees and confirmed component availability.

Can these suppliers support small-batch or prototype orders?

Yes. Most leading suppliers accept MOQs as low as 1 unit for evaluation samples. Volume discounts apply at 5–50 units depending on complexity. Prototypes typically include full functionality testing and basic configuration validation.

Do suppliers offer after-sales technical support?

Top performers like Shenzhen Zunsia and Wuhan Haoqing provide multilingual engineering support for driver integration, system diagnostics, and firmware updates. Request service-level agreements (SLAs) covering response windows and remote troubleshooting availability prior to purchase.

How to validate product authenticity and avoid counterfeit components?

Insist on original Intel box packaging, serial number traceability, and batch verification via Intel’s authorized distributor network. Conduct pre-shipment inspections using third-party auditors to verify BOM alignment and conduct stress tests on received units.