Interfacing Handling And Storage With Manufacturing

CN

CN

About interfacing handling and storage with manufacturing

Where to Find Interfacing, Handling, and Storage Solutions for Manufacturing?

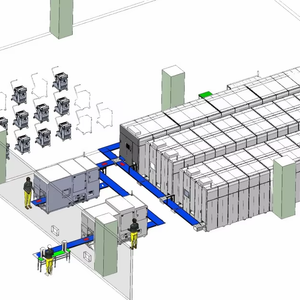

China remains a central hub for integrated manufacturing support systems, with specialized suppliers concentrated in industrial zones across Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically aligned production ecosystems capable of delivering components and equipment for interfacing, material handling, and storage automation. Shenzhen-based electronics integrators supply semiconductor-level interface ICs, while Wenzhou and Nanjing manufacturers specialize in industrial textiles and steel racking infrastructure, respectively. This geographic diversification enables buyers to source both micro-scale electronic components and macro-scale logistics systems from a single regional network.

The clustering effect reduces lead times through localized supply chains—raw materials, processing, assembly, and packaging often occur within 100km radii. Suppliers benefit from shared technical labor pools and streamlined export logistics via major ports like Ningbo and Shenzhen. Buyers gain access to scalable production runs, with standard order fulfillment averaging 25–40 days depending on product complexity. Cost efficiencies range from 18–35% compared to equivalent Western-sourced solutions, driven by lower overhead and high-volume manufacturing density.

How to Choose Interfacing, Handling, and Storage Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm alignment between supplier offerings and application requirements. For electronic interface components (e.g., transceivers, drivers), verify compatibility with communication protocols such as RS-485, CAN bus, or I²C. In textile-based interfacing materials like fusible interlinings, assess fiber composition (polyester, viscose) and thermal bonding performance. For storage racks and handling equipment, validate load capacity specifications (ranging from 20kg to over 1 ton per unit) and structural integrity under dynamic loading conditions.

Production Infrastructure Assessment

Evaluate the following indicators of manufacturing maturity:

- Minimum facility area exceeding 3,000m² for equipment-focused suppliers

- In-house design and engineering teams supporting custom configurations

- Use of precision fabrication methods: CNC machining, automated welding, or roll-to-roll coating for nonwovens

Cross-reference online revenue data and listing volume with on-time delivery records (target ≥98%) to assess operational stability.

Quality and Compliance Standards

While formal certifications are not universally listed, prioritize suppliers demonstrating consistent quality control. Look for evidence of standardized testing procedures, especially for electrical components subject to EMI/EMC regulations. Where applicable, confirm RoHS compliance for ICs and REACH conformity for chemical-treated fabrics. Request product datasheets and, where feasible, batch-specific test reports prior to full-scale procurement.

What Are the Leading Interfacing, Handling, and Storage Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Shenzhen MINCONDA Technology Co., Ltd. | Guangdong, CN | Interface ICs, Memory, PMICs | Not specified | 100.0% | ≤1h | US $40,000+ | <15% | $0.10/piece |

| Wenzhou Xinyu Non-Woven Fabric Co., Ltd. | Zhejiang, CN | Fusible Interlinings, Nonwoven Fabrics | Material, weight, roll size | 100.0% | ≤5h | Not available | Not available | $3,000/ton |

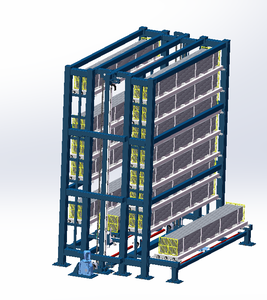

| Nanjing Peter Logistics Equipment Co., Ltd. | Jiangsu, CN | Steel Racks, Pallet Systems, Mezzanines | Color, frame design, capacity, labeling | 100.0% | ≤3h | US $60,000+ | 20% | $0.80/kg |

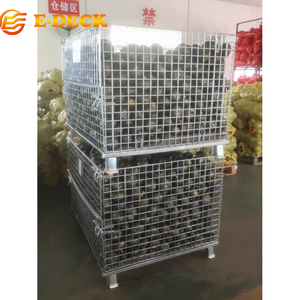

| Foshan Shunjie Doors Windows Machinery Equipment Co., Ltd. | Guangdong, CN | Material Carts, Stacking Racks, Handling Frames | Load capacity, folding design, multi-tier structure | 100.0% | ≤4h | US $140,000+ | 50% | $220/unit |

| Gansu Sanyang Storage Equipment Manufacturing Co., Ltd. | Gansu, CN | Adjustable Racking, Lightweight Steel Shelving | Size, color, material, logo, packaging | 100.0% | ≤5h | US $100,000+ | <15% | $7.65/set |

Performance Analysis

Shenzhen MINCONDA leads in component-level interfacing technology, offering low-cost ICs suitable for high-volume electronics integration, though its low reorder rate suggests limited after-sales engagement. Wenzhou Xinyu specializes in textile-based interfacing materials with bulk-order pricing advantageous for apparel and upholstery manufacturers. Nanjing Peter and Gansu Sanyang provide engineered storage solutions with extensive customization, ideal for warehouse automation upgrades. Foshan Shunjie stands out with a 50% reorder rate, indicating strong customer satisfaction in durable handling equipment. All top-tier suppliers maintain 100% on-time delivery, a critical benchmark for just-in-time manufacturing environments.

FAQs

What are typical MOQs for interfacing and storage products?

Minimum order quantities vary significantly by product type. Electronic ICs are available from 1 piece ($0.10–1.00/unit). Nonwoven interfacing fabrics require 1 ton (from $2,900). Storage racks start at 10 sets ($7.65–16.80/set). Material handling carts are priced per unit with MOQs of 1–3 pieces.

How long do custom orders take to fulfill?

Standard lead time ranges from 25–35 days post-design approval. Custom rack systems or specialized IC configurations may extend to 45 days. Textile dyeing and lamination processes add 7–10 days for color-specific nonwoven orders.

Can suppliers provide product samples?

Yes, most suppliers offer samples. ICs are typically provided free for qualified buyers. Fabric samples cost $50–150 depending on treatment complexity. Structural equipment samples (e.g., rack segments) incur fees covering material and shipping, usually refundable against future orders.

What customization options are available?

Suppliers support dimensional adjustments, load ratings, surface finishes, and branding (logo imprinting). Electronics vendors can assist with pin configuration and voltage tolerance. Fabric producers adjust melt-point adhesives for different fabric substrates. Racking systems allow modular layering, mezzanine integration, and color coding.

Are there export-ready packaging and documentation standards?

Established suppliers use export-grade wooden crates or reinforced cartons with moisture barriers. Documentation includes packing lists, commercial invoices, and material declarations. Buyers should specify destination country regulations—especially for electrical goods requiring CE or FCC markings.