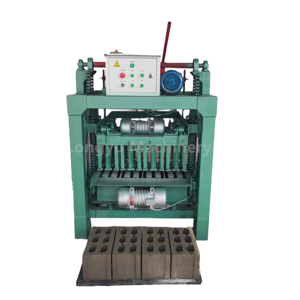

Interlocking Blocks Machine

Top sponsor listing

Top sponsor listing

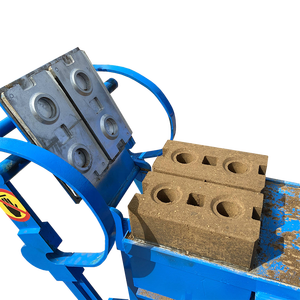

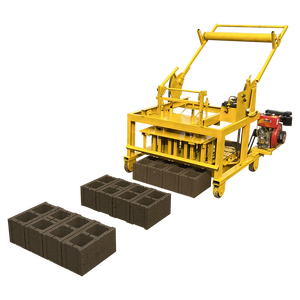

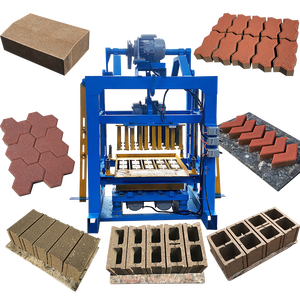

About interlocking blocks machine

Where to Find Interlocking Blocks Machine Suppliers?

China remains the global epicenter for interlocking blocks machine manufacturing, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, heavy fabrication, and final assembly under one supply chain. Shandong’s Jining and Qingdao zones are known for high-capacity automated systems and proximity to steel suppliers, reducing component costs by 15–20%. Henan, particularly around Zhengzhou, supports over half of China’s brick-making machinery output, leveraging dense networks of foundries, hydraulic system manufacturers, and logistics hubs.

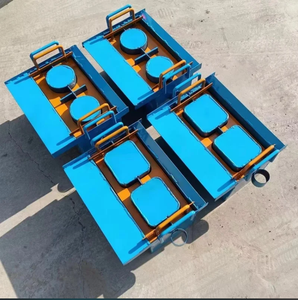

The clustering effect enables rapid prototyping and scalable production, with many facilities capable of fulfilling orders from prototype to container load within 30–45 days. Buyers benefit from localized access to molds, vibratory tables, conveyors, and batching plants—critical subsystems integrated into complete block production lines. The region’s mature infrastructure supports both standard models (e.g., QT4-15, QT4-35) and engineered solutions tailored to local building codes, raw material types, or energy sources (diesel/electric).

How to Choose Interlocking Blocks Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify adherence to international quality benchmarks such as ISO 9001. For export markets, confirm CE marking or equivalent safety certifications. Assess design flexibility: leading suppliers offer customization in block size, mold configuration (solid/hollow), vibration frequency, power source, and automation level (manual, semi-auto, fully automatic). Request detailed specifications including hydraulic pressure ratings, cycle time per batch, and compatibility with local aggregates.

Production Infrastructure Audit

Evaluate core capabilities through verifiable metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams supporting CAD-based layout planning and 3D modeling

- Integrated CNC machining, welding, and heat treatment processes

Cross-reference on-time delivery rates (>95%) and response times (<3 hours) as proxies for operational efficiency and customer service capacity.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery technical support. Analyze reorder rates as an indicator of customer satisfaction—rates above 30% suggest strong reliability and service performance. Confirm availability of spare parts, operator training, and remote troubleshooting services, especially for automated systems requiring calibration.

What Are the Best Interlocking Blocks Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range Highlights | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Brick Making Machinery, Concrete Batching Plant, Mixers | US $390,000+ | 100% | ≤2h | 66% | Semi-auto to full-auto models, paver & hollow block variants | Block size, color, mold shape, power source, hydraulic station type |

| Henan Best Link Import And Export Trading Co., Ltd. | Henan, CN | Brick Making Machinery, Mining Equipment, Chemical Agents | US $250,000+ | 100% | ≤1h | <15% | QT4-15 hydraulic models, manual to fully automatic systems | Limited customization reported; focus on standard configurations |

| Shandong Brick Machinery Co., Ltd. | Shandong, CN | Brick Making Machinery, Loaders, Pallets | US $140,000+ | 100% | ≤1h | 33% | QT4-35B, QT8-15, manual and semi-automatic units | Mold variations, automation level, conveyor integration |

| LONTA MACHINERY CO.,LTD | Shandong, CN | Concrete Mixers, Compactors, Construction Machinery | US $40,000+ | 87% | ≤3h | <15% | QTJ4-25, QMJ4-40, mobile and stationary models | Automation grade, mobility options, mold design |

| Changge Hengruide Machinery Equipment Co., Ltd. | Henan, CN | Manual Block Machines, Crushers, Drilling Rigs | US $10,000+ | 100% | ≤1h | 16% | Household-scale manual machines, low-cost entry models | Basic size adjustments; minimal automation features |

Performance Analysis

Shandong-based suppliers dominate in scalability and customization depth, with Shandong Hongfa standing out due to its high reorder rate (66%) and extensive configurability across block type, automation, and auxiliary systems. Its integration of batching plants and conveyors positions it well for turnkey line installations. Henan Best Link and Shandong Brick Machinery demonstrate strong logistical responsiveness (≤1h average reply time) and perfect on-time delivery records, though lower reorder rates suggest room for improvement in long-term client retention. LONTA MACHINERY offers diverse model ranges but lags in delivery consistency (87%). Changge Hengruide serves niche demand for affordable manual units priced under $120/unit, ideal for micro-enterprises or rural construction projects.

FAQs

What is the typical MOQ and lead time for interlocking blocks machines?

Minimum order quantity is typically 1 set across all suppliers. Lead times range from 15 to 30 days depending on automation level—manual models ship fastest, while fully automatic lines may require additional calibration and testing before dispatch.

Can suppliers customize machine specifications?

Yes, reputable manufacturers support customization of block dimensions, mold patterns (interlock design, paver shapes), vibration intensity, hydraulic system type (diesel/electric), and integration with conveyor belts or silos. Advanced suppliers provide technical drawings and simulation layouts upon request.

Do interlocking blocks machines comply with international standards?

Compliance varies by manufacturer. Top-tier suppliers align with ISO 9001 quality management systems and may provide CE-certified models upon request. Buyers should explicitly request test reports for structural integrity, electrical safety, and noise levels prior to purchase.

Are spare parts and technical support available post-purchase?

Most established suppliers offer comprehensive after-sales packages, including spare part kits, operation manuals, and remote guidance. Some provide on-site installation support or video tutorials for maintenance procedures, particularly for hydraulic and control systems.

What are the common power and material requirements?

Machines operate on single-phase (220V) or three-phase (380V) power supplies, depending on automation grade. They process standard concrete mixes using cement, sand, gravel, or fly ash. Optimal feed consistency and aggregate size must be matched to the machine’s hopper and compaction system to ensure uniform block density and strength.