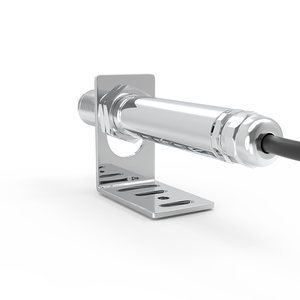

Ir Temperature Sensor

Top sponsor listing

Top sponsor listing

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/21

1/21

1/3

1/3

1/1

1/1

1/11

1/11

1/32

1/32

About ir temperature sensor

Where to Find IR Temperature Sensor Suppliers?

China remains a central hub for infrared (IR) temperature sensor manufacturing, with key production clusters in Hunan, Jiangsu, and Liaoning provinces. These regions host specialized electronics and industrial instrumentation manufacturers that benefit from mature supply chains for optical components, microprocessors, and thermal detection modules. Hunan and Jiangsu, in particular, are home to vertically integrated facilities capable of handling full-cycle production—from sensor calibration to signal processing unit assembly—enabling consistent output and competitive pricing.

The concentration of technical suppliers in these zones supports rapid prototyping and scalable production. Industrial ecosystems in Changsha (Hunan) and Wuxi (Jiangsu) include certified testing labs, precision machining workshops, and packaging specialists within close proximity, reducing component lead times by up to 25%. Buyers can expect standard order fulfillment within 15–30 days, with cost advantages of 20–35% over European or North American equivalents due to localized sourcing of materials such as germanium lenses, thermopile detectors, and stainless-steel housings.

How to Choose IR Temperature Sensor Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Confirm adherence to international quality standards such as ISO 9001 and compliance with RoHS directives for hazardous substance control. For industrial applications, verify sensor specifications including emissivity adjustment range (typically 0.1–1.0), response time (<1 second), and accuracy (±1–2% of reading). Output signal types—such as 4–20mA, RS485, or digital display integration—should align with automation system requirements.

Production Infrastructure Assessment

Evaluate supplier capabilities based on the following criteria:

- Facility size and dedicated R&D capacity for custom configurations

- In-house calibration and environmental testing (e.g., high-temperature stability up to 1200°C)

- Support for OEM/ODM services including laser marking, label customization, and packaging design

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours) as indicators of operational efficiency.

Procurement Risk Mitigation

Utilize secure transaction mechanisms such as escrow payment systems until product verification is complete. Request sample units to validate performance under real-world conditions, particularly for non-contact measurement in high-emissivity environments (e.g., metal processing). Prioritize suppliers with documented export experience and multilingual technical support for seamless communication.

What Are the Best IR Temperature Sensor Suppliers?

| Company Name | Verified Type | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Hunan Firstrate Sensor Co., Ltd. | Custom Manufacturer | Pressure Sensors, Pressure Transmitters, Level Measuring Instruments | 98% | 23% | ≤2h | US $600,000+ | Color, material, size, logo, RS485, packaging, graphic |

| Jiangsu Aice Instrument Technology Co., Ltd. | Multispecialty Supplier | Temperature Sensor, Infrared | 100% | 24% | ≤2h | US $190,000+ | Output signal, cable length, cooling jacket, explosion-proof, diameter, material, temperature range, Wi-Fi, thread size, digital display, RS485 |

| Honno (Shenyang) General Machinery Co., Ltd. | Unverified | Flow Meters, Flow Sensors, Temperature Instruments | 100% | <15% | ≤2h | US $7,000+ | Limited data available |

| Shenzhen Chuangwei Automation Co., Ltd. | Unverified | Optical Sensors, Temperature Sensors, Proximity Sensors | 100% | 22% | ≤1h | US $20,000+ | Honeywell-based models, thermostat integration |

| Shenzhen Chuangheying Electronic Technology Co., Ltd. | Unverified | Thermal Imagers, Non-Contact Thermometers | 100% | <15% | ≤7h | US $1,300,000+ | Model-specific variants (UTi120S, UT303A, etc.) |

Performance Analysis

Hunan Firstrate Sensor and Jiangsu Aice demonstrate strong customization depth and consistent delivery performance, making them suitable for bulk industrial procurement. Jiangsu Aice stands out with extensive parameter-level configurability, including Wi-Fi communication and explosion-proof designs for hazardous environments. Shenzhen Chuangheying reports the highest online revenue, indicating robust market presence, though its slower response time suggests potential bottlenecks in customer service scalability. Suppliers with reorder rates above 20%—including Hunan Firstrate and Jiangsu Aice—demonstrate higher customer satisfaction and product reliability. For mission-critical applications, prioritize manufacturers offering traceable calibration certificates and compatibility with SCADA or PLC integration.

FAQs

How to verify IR temperature sensor supplier reliability?

Validate certifications through official registries and request product test reports, including blackbody calibration curves and EMI/EMC compliance documentation. Analyze transaction history, focusing on dispute resolution records and verified buyer feedback related to measurement accuracy and long-term stability.

What is the typical MOQ and lead time?

Minimum order quantities range from 1 piece for standard models to 10 pieces for bulk-configured sensors. Lead times average 10–20 days post-payment, depending on customization level. Sample orders typically ship within 5–7 business days.

Do suppliers offer customization for industrial integration?

Yes, leading suppliers provide tailored solutions including analog/digital output configuration, specialized threading, cooling jackets, and RS485 Modbus protocols. Custom firmware and multi-point monitoring setups are available upon technical review.

Are samples available before full procurement?

Most suppliers offer paid samples, with costs often credited toward subsequent orders. Pricing ranges from $30–$200 depending on model complexity. Thermal imagers and high-range sensors may require non-refundable sampling fees.

Can IR sensors be used in high-temperature industrial processes?

Affirmative. Models rated up to 1200°C are commercially available, commonly used in aluminum smelting, glass manufacturing, and kiln monitoring. Ensure proper selection of spectral response (short-wave vs. long-wave IR) and inclusion of air-purge or water-cooling accessories for sustained operation.