Jacket Patch Maker

About jacket patch maker

Where to Find Jacket Patch Maker Suppliers?

China remains the global epicenter for custom patch manufacturing, with key production clusters in Zhejiang, Guangdong, and Jiangsu provinces driving innovation and cost efficiency. These regions host vertically integrated facilities capable of handling full-cycle production—from digital design and embroidery programming to heat transfer, chenille weaving, and PVC molding. Yiwu and Kunshan serve as major export hubs due to their proximity to Shanghai and Ningbo ports, enabling faster logistics turnaround for international buyers.

The industrial ecosystem supports both mass production and high customization, with many factories operating automated embroidery lines capable of producing 50,000+ units monthly. Material sourcing is localized, including synthetic twill, felt, nylon, and heat-seal adhesives, reducing lead times by up to 25% compared to offshore alternatives. Buyers benefit from flexible MOQs (as low as 5–10 pieces), rapid prototyping (3–7 days), and scalable output for bulk orders exceeding 10,000 units.

How to Choose Jacket Patch Maker Suppliers?

Selecting a reliable supplier requires evaluating technical capability, quality assurance, and transaction reliability through structured verification protocols:

Production & Customization Capabilities

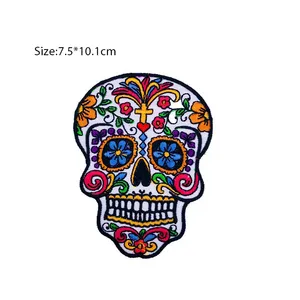

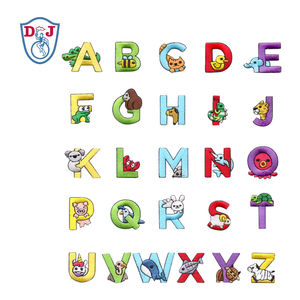

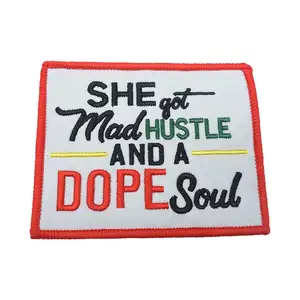

Confirm access to multiple fabrication techniques: embroidered, woven, chenille, PVC, silicone rubber, and iron-on/heat-press applications. Leading suppliers offer digitization services for logo conversion, backing options (heat-seal, sew-on, velcro), and material thickness ranging from 0.4mm to 1.2mm. In-house design teams should support vector editing, color matching (Pantone standards), and 3D mockup generation.

Quality Management Systems

While formal ISO certification is not universally reported, prioritize suppliers with documented QC checkpoints—pre-production sampling, in-line inspection, and final batch testing. Key performance indicators include stitch density (≥900–1,200 stitches per patch), edge durability (anti-fray stitching or laser-cut sealing), and colorfastness after washing (tested at 40°C for 30 minutes). Request product certifications for RoHS compliance if exporting to EU markets.

Order Flexibility and Transaction Metrics

Evaluate responsiveness (target ≤3 hours), on-time delivery rate (benchmark ≥97%), and reorder frequency. Low MOQs (5–25 pieces) are common for sample validation, while unit pricing typically scales down at 500+ and 5,000+ thresholds. Verified suppliers often provide revision policies for design adjustments and maintain online revenue streams exceeding US $50,000 annually, indicating consistent export activity.

What Are the Best Jacket Patch Maker Suppliers?

| Company Name | Main Products | Customization Support | Min. Order Quantity | Avg. Unit Price (USD) | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Quality Punch, Inc. | Patches, Metal Crafts, Fashion Brooches | Limited data | 10 pieces | $1.95–2.30 | Data unavailable | ≤8h | Data unavailable | Data unavailable |

| Yiwu Yifeng Clothing Accessories Co., Ltd. | Patches, Trucker Hats, Garment Labels | Embroidery, Iron-on, Tactical Patches | 10–20 pieces | $0.09–4.62 | 96% | ≤3h | 23% | US $50,000+ |

| Kunshan Zhisong Arts&crafts Co., Ltd. | Metal Crafts, Patches, Key Chains | Custom Embroidery, Iron-on, Crystal Accents | 5–25 pieces | $0.09–0.50 | 100% | ≤2h | 20% | US $60,000+ |

| Yiwu Dijianhua Import And Export Co., Ltd. | Patches | Chenille, Large Format, Sustainable Materials | 20–50 pieces | $0.23–3.42 | 97% | ≤1h | 15% | US $20,000+ |

| Changsha Davina Patches Co.,Ltd. | Custom Embroidered Patches, Clothing Badges | Full-range: Woven, Chenille, PVC, Heat Transfer, UV Printing | 10–50 pieces | $0.10–0.90 | 99% | ≤3h | 33% | US $420,000+ |

Performance Analysis

Changsha Davina Patches stands out with the highest online revenue (US $420,000+) and a 33% reorder rate, reflecting strong customer retention and broad customization capacity. The company supports advanced techniques like UV printing, gradient embroidery, and anti-piling fabrics, making it suitable for complex branding projects. Kunshan Zhisong leads in punctuality (100% on-time delivery) and responsiveness (≤2h), ideal for time-sensitive campaigns. Yiwu-based suppliers offer competitive pricing and low MOQs, particularly for novelty and fashion-driven designs. Quality Punch, Inc. operates at a higher price point ($1.95+), suggesting specialization in premium chenille or varsity-style patches, though limited performance data restricts comparative assessment.

FAQs

What materials are commonly used by jacket patch makers?

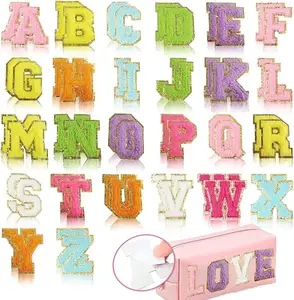

Standard substrates include polyester twill, felt, nylon, and velvet, with backings such as heat-activated adhesive (for iron-on), merrowed edges, or velcro integration. PVC and silicone rubber are used for 3D emblems, while chenille yarns create vintage-style lettering for varsity jackets.

How long does it take to receive samples?

Sample production typically takes 3–7 business days, depending on complexity. Shipping via express courier adds 5–10 days internationally. Digital proofs are usually provided within 24–48 hours of order confirmation.

Can suppliers replicate copyrighted logos or trademarks?

No reputable manufacturer will produce protected intellectual property without authorization. Buyers must provide written consent or licensing documentation to avoid legal liability. Suppliers may require signed indemnification forms before production.

What are typical payment terms for first-time orders?

Common arrangements include 30–50% deposit with balance prior to shipment. Escrow services or platform-backed transactions are recommended for initial engagements. Larger buyers may negotiate net-30 terms after establishing transaction history.

Do jacket patch makers support eco-friendly production?

Some suppliers offer sustainable options, including recycled fabric bases, water-based adhesives, and low-impact dyes. Yiwu Dijianhua Import And Export Co., Ltd. explicitly references sustainable materials in its product line, indicating environmental compliance readiness.