Jam Processing Machine

Top sponsor listing

Top sponsor listing

1/15

1/15

1/12

1/12

1/18

1/18

1/24

1/24

1/21

1/21

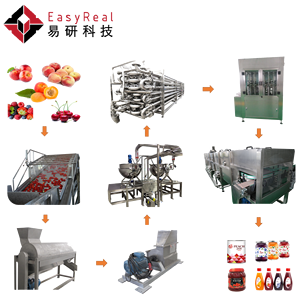

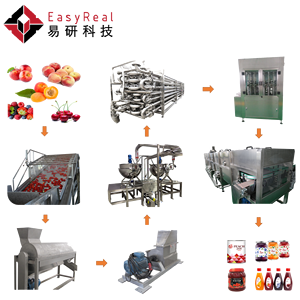

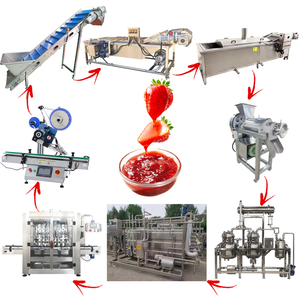

About jam processing machine

Where to Find Jam Processing Machine Suppliers?

China remains the global hub for jam processing machine manufacturing, with key production clusters in Jiangsu, Henan, and Shanghai offering specialized capabilities. Jiangsu excels in high-automation food processing lines, integrating advanced thermal control and mixing systems for consistent batch quality. Henan’s suppliers focus on cost-effective, compact machinery suited for small to mid-scale producers, leveraging regional economies of scale in electromechanical components. Shanghai-based manufacturers specialize in fully customized turnkey solutions, often combining jam processing with integrated filling, sterilization, and packaging modules.

These industrial zones benefit from vertically integrated supply chains—local access to stainless steel fabrication, heating elements, and control systems reduces component lead times by 20–30%. Proximity to major ports like Shanghai and Qingdao enables efficient containerized shipping, with standard export documentation support. Buyers can expect typical production lead times of 30–60 days depending on automation level, with modular designs allowing rapid reconfiguration for different fruit types or viscosity requirements.

How to Choose Jam Processing Machine Suppliers?

Procurement decisions should be guided by technical, operational, and transactional verification protocols:

Technical Compliance & Certification

Confirm adherence to international food safety standards. Essential certifications include ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For exports to North America or Europe, verify FDA-compliant material usage (e.g., AISI 304/316 stainless steel contact surfaces) and compliance with hygiene design principles (smooth welds, drainable surfaces, CIP compatibility).

Production Capacity Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area of 2,000m² indicating dedicated production space

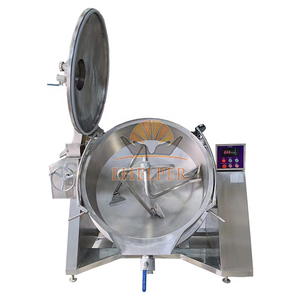

- In-house engineering teams capable of customizing agitation speed, heating methods (jacketed vessels, steam/electric), and integration with upstream/downstream units

- Proven experience in delivering complete processing lines—not just standalone machines

Cross-reference delivery performance (target ≥95%) and response time (≤3 hours) as indicators of operational reliability.

Customization & Quality Assurance

Leading suppliers offer customization in vessel capacity (50L–5,000L), material finish, control panel language, and automation level (manual, semi-auto, full PLC). Demand validation through test reports on temperature uniformity, sealing integrity, and motor durability. Request video audits of assembly processes, especially for critical components like agitators and heat exchangers.

Transaction Security

Utilize secure payment mechanisms such as escrow services for initial large orders. Prioritize suppliers with documented after-sales support, including installation guidance, spare parts availability, and remote troubleshooting. Analyze reorder rates (<15% indicates limited repeat business; >30% suggests customer satisfaction) and online transaction volume as indirect performance indicators.

What Are the Best Jam Processing Machine Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|

| Jiangsu Lazen Machinery Technology Co., Ltd. | Fruit & Vegetable Machines, Dairy & Beverage Processing Lines | Color, material, size, logo, packaging, label, graphic | 100% | ≤2h | <15% | - | 14+ models across processing stages |

| Henan Xinjusheng Trading Co., Ltd. | Fruit & Vegetable Machines, Snack & Packaging Equipment | Limited customization data | 100% | ≤3h | <15% | US $130,000+ | 5 listed machines, price range $130–$1,680 |

| XIWANG TECHNOLOGY INC | Food Processing Lines, Packaging & Cutting Machines | Full line customization available | - | ≤2h | - | - | 5 high-capacity production lines ($4,800–$16,000) |

| Shanghai Qingji Beverage Machinery Co., Ltd. | Dairy & Beverage Processing, Filling & Sterilizing Systems | Complete line customization | 50% | ≤6h | 50% | US $280,000+ | 5 systems, premium segment ($20,000–$300,000) |

| Luohe Langrui Electromechanical Equipment Co., Ltd. | Jam & Sauce Machines, Juicers, Peanut Butter Equipment | Speed, capacity, lid type, material, color, plug, packaging | 99% | ≤2h | 15% | US $410,000+ | 5 models, mid-range pricing ($539–$7,888) |

Performance Analysis

Jiangsu Lazen and Luohe Langrui demonstrate strong operational efficiency with 100% and 99% on-time delivery, respectively, and rapid ≤2-hour response times—critical for urgent procurement cycles. While Jiangsu Lazen offers broad product diversity and deep customization, its low reorder rate suggests room for improvement in long-term client retention. Luohe Langrui stands out for mid-tier buyers, balancing competitive pricing with robust technical options and high responsiveness.

Shanghai Qingji targets high-end clients with fully automated, large-scale production lines, reflected in prices exceeding $200,000. Despite a lower on-time delivery rate (50%), its 50% reorder rate indicates strong post-sale satisfaction among existing clients, likely due to system integration expertise. Conversely, Henan Xinjusheng provides entry-level machinery ideal for startups, though limited customization data warrants further due diligence. XIWANG TECHNOLOGY positions itself as a custom line builder but lacks verifiable delivery and reorder metrics, introducing supply chain risk.

FAQs

How to verify jam processing machine supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request factory audit reports or video walkthroughs of production floors. Analyze transaction history, focusing on consistent delivery performance and customer feedback related to machine durability and after-sales service.

What is the typical MOQ and lead time?

Most suppliers set MOQ at 1 unit or set. Lead times vary: 30–45 days for standard models; 60+ days for fully customized lines requiring engineering design and testing phases.

Can suppliers customize jam processing machines?

Yes, leading suppliers offer customization in tank volume, heating method (steam jacket, electric), agitation speed, control interface (PLC/HMI), and integration with feeding, cooking, and filling systems. Full turnkey lines are available upon technical specification submission.

Do manufacturers provide samples or prototypes?

Full-machine sampling is uncommon due to size and cost. However, reputable suppliers provide detailed 3D renderings, component specifications, and test videos. Some may offer pilot-scale trials for large-volume buyers under negotiated terms.

What are common materials used in construction?

Food-grade AISI 304 or 316 stainless steel is standard for contact surfaces. Seals are typically silicone or EPDM. Motors and structural frames use carbon steel with anti-corrosion coating. Verify material certificates for hygienic compliance.