Jwt Npm

1/28

1/28

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/2

1/2

1/3

1/3

About jwt npm

Where to Find jwt npm Suppliers?

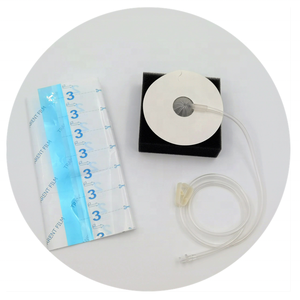

The global supply base for products associated with "jwt npm" is concentrated among specialized manufacturers in China, primarily in the Guangdong and Tianjin regions. These hubs host technically focused firms engaged in precision manufacturing for medical devices and electronics production systems. Tianjin-based suppliers leverage proximity to research institutions and polymer material suppliers, enabling rapid prototyping of wound care solutions. Meanwhile, Shenzhen’s industrial ecosystem supports high-mix, low-volume production of surface mount technology (SMT) machine components, benefiting from dense networks of electronic parts distributors and automation engineers.

These clusters facilitate vertical integration in both medical and industrial equipment supply chains. Medical-focused suppliers operate cleanroom environments for sterile dressing assembly, while those serving the electronics sector maintain calibrated testing stations for SMT nozzles and feeders. Buyers access a dual-supply model: one stream dedicated to disposable medical foam dressings and NPWT kits, the other to durable SMT machine spares and calibration tools. This bifurcation allows cost optimization—medical consumables are produced at scale (MOQs from 500 sets), whereas industrial parts support single-unit sampling with fast turnaround.

How to Choose jwt npm Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Product Category Alignment

Clearly define whether the procurement objective targets medical wound therapy products or SMT machine components, as these represent distinct product families. Misalignment leads to sourcing inefficiencies. For NPWT foam dressings and vacuum-assisted closure kits, prioritize suppliers with ISO 13485 certification and sterile packaging capabilities. For NPM-series SMT nozzles, feeder calibrators, or mounting heads, verify compatibility specifications with Fuji, Panasonic, or Siemens platforms.

Quality and Compliance Verification

Confirm adherence to relevant standards:

- Medical device suppliers should provide evidence of ISO 13485, CE marking under MDR, and biocompatibility testing (ISO 10993)

- Industrial part suppliers must demonstrate traceability for wear-resistant materials (e.g., tungsten carbide nozzles) and dimensional accuracy within ±0.02mm

- Cross-check online revenue indicators and reorder rates—suppliers with reorder rates above 40% (e.g., Shenzhen Miao Mu Electronic Technology Co., Ltd.) suggest higher customer satisfaction and product reliability

Production and Customization Capacity

Assess flexibility for labeling, material substitution, or private branding. Multiple suppliers list customization options for color, logo, packaging, and graphic design—critical for OEM partnerships. For industrial clients, confirm availability of CAD drawings, calibration certificates, and spare part cross-referencing databases. Evaluate response time metrics; sub-1-hour average responses indicate robust customer service infrastructure.

What Are the Best jwt npm Suppliers?

| Company Name | Location | Main Product Focus | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Offered | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| JcMed (TIANJIN) IMPORT&EXPORT CO., LTD. | Tianjin, CN | Negative Pressure Wound Therapy Foam | US $60,000+ | 92% | ≤4h | 22% | Yes | 5–500 pieces |

| Shenzhen TDX Electromechanical Equipment Co., Ltd. | Shenzhen, CN | SMT Machine Parts & Systems | US $90,000+ | 100% | ≤3h | <15% | No explicit mention | 1 piece/set |

| Shenzhen Liancheng Automation Co., Ltd. | Shenzhen, CN | SMT Nozzle Holders & Mounting Parts | US $10,000+ | 100% | ≤3h | <15% | No explicit mention | 1 set/bag |

| Shenzhen Miao Mu Electronic Technology Co., Ltd. | Shenzhen, CN | SMT Nozzles & Feeder Components | US $80,000+ | 100% | ≤1h | 42% | Not specified | 1 piece |

| Shandong Safecare Medical Co., Ltd. | Shandong, CN | NPWT Kits & Surgical Dressings | US $8,000+ | 93% | ≤3h | <15% | Yes | 200–500 sets |

Performance Analysis

Shenzhen Miao Mu Electronic Technology stands out with a 42% reorder rate and ≤1-hour response time, indicating strong customer retention in the competitive SMT components market. JcMed (Tianjin) and Shandong Safecare serve the medical segment with flexible MOQs starting at 5 units, ideal for pilot testing wound therapy products. Industrial suppliers like Shenzhen TDX and Liancheng offer high-value items such as full SMT mounters ($130k+) and precision nozzles, catering to capital equipment maintenance needs. While medical suppliers emphasize customization in packaging and materials, industrial players focus on technical interchangeability and durability. Prioritize suppliers with documented quality systems and verifiable delivery performance—especially critical when sourcing sterile medical disposables or mission-critical machine parts.

FAQs

How to verify jwt npm supplier reliability?

Validate certifications relevant to the product type: ISO 13485 for medical dressings, ISO 9001 for industrial components. Request test reports for material composition and performance (e.g., tensile strength for silicone hoses, airflow consistency for NPWT foam). Analyze platform-derived metrics including on-time delivery rate (>90% recommended) and response time (under 4 hours preferred).

What is the typical lead time for samples?

Sample processing ranges from 5–15 days depending on complexity. Simple SMT nozzles or adhesive dressings ship faster; fully assembled NPWT kits or calibrated feeders may require additional quality checks. Air freight adds 7–10 days for international delivery.

Can suppliers accommodate small orders?

Yes. Several suppliers accept MOQs as low as 1 piece (for SMT nozzles) or 5 units (for foam dressings), reducing entry risk for new buyers. However, unit prices decrease significantly at 500-piece thresholds, especially for molded or laminated products.

Do suppliers support private labeling and packaging?

At least two suppliers explicitly list customization options for logo, color, label, and graphic design—particularly in the medical consumables segment. Confirm artwork requirements and setup fees before order placement.

What payment and transaction safeguards are available?

Buyers should utilize secure payment methods with escrow functionality to mitigate risk. Review supplier transaction history, focusing on dispute resolution outcomes and customer feedback related to product accuracy and after-sales communication.