Key Cutter And Programmer

Top sponsor listing

Top sponsor listing

About key cutter and programmer

Where to Find Key Cutter and Programmer Suppliers?

China remains the central hub for key cutter and programmer manufacturing, with Shenzhen and Qingdao emerging as primary production clusters. These regions host vertically integrated supply chains that combine precision machining, electronic component sourcing, and firmware development under one ecosystem. Shenzhen’s specialization in automotive electronics enables rapid prototyping and firmware updates critical for vehicle key programming tools, while Qingdao’s industrial base supports high-volume production of mechanical key cutting equipment.

The concentration of suppliers in these zones facilitates economies of scale, reducing per-unit costs by 20–35% compared to Western manufacturers. Proximity to component suppliers—such as servo motors, CNC modules, and microcontroller units—ensures shorter lead times, typically 15–30 days for standard orders. Buyers benefit from access to mature logistics networks, enabling efficient air and sea freight coordination for global distribution. The presence of technical talent pools also allows suppliers to maintain dedicated R&D teams focused on expanding vehicle compatibility databases and enhancing user interface design.

How to Choose Key Cutter and Programmer Suppliers?

Selecting reliable partners requires adherence to structured evaluation criteria:

Technical Capability Verification

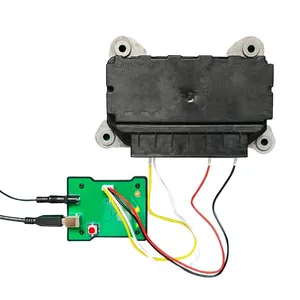

Confirm supplier expertise in both mechanical engineering (for key cutters) and embedded software systems (for programmers). Evaluate product portfolios for evidence of dual-function devices (e.g., 2-in-1 multifunctional tools), which indicate advanced integration capabilities. Prioritize companies offering regular firmware updates and broad OEM vehicle coverage, including modern immobilizer systems and smart key protocols.

Production and Quality Assurance

Assess operational infrastructure through verifiable metrics:

- On-time delivery rate exceeding 96%

- Response time under 6 hours for buyer inquiries

- In-house testing procedures for electronic stability and blade precision

Cross-reference performance tags with transaction history. Suppliers reporting online revenues above US $150,000 demonstrate consistent output and market validation.

Customization and Compliance

Verify capacity for customization across material finishes, branding (logo/label), packaging, and functional parameters such as battery type or plug configuration. Ensure compliance with international standards including CE, RoHS, and FCC where applicable, particularly for wireless communication modules in key programmers. Request documentation for electromagnetic compatibility (EMC) testing if exporting to EU or North American markets.

What Are the Best Key Cutter and Programmer Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Product Range Highlights |

|---|---|---|---|---|---|---|---|

| Shenzhen Xing Chen Technology Trading Company Ltd. | Diagnostic Tools, Vehicle Keys, TPMS, Auto Sensors | US $340,000+ | 100% | ≤6h | 36% | Color, material, size, logo, packaging, label, graphic | Mid-range programmers, locksmith supplies |

| Qingdao Everise Int'l Co., Ltd. | Key Cutting Machines, Copiers, Portable Cutters | US $150,000+ | 100% | ≤4h | 50% | Blade type, color, size, logo, plug, battery, key type | Automatic CNC cutters, universal models |

| Chengdu Daobo Technology Co., Ltd. | Diagnostic Tools, Vehicle Keys, Interior Accessories | US $250,000+ | 96% | ≤5h | 21% | Limited customization noted | Premium automatic cutters (Xhorse Dolphin XP005) |

| Shenzhen Jindong Network Technology Co., Ltd. | Car Key Programmers, Diagnostic Tools | US $60,000+ | 100% | ≤2h | 19% | No explicit customization listed | Lonsdor K518 PRO, Xhorse VVDI Mini |

| Shenzhen Deyixing Technology Co., Ltd. | Diagnostic Tools, Car Locksmith Tools | US $20,000+ | 97% | ≤3h | <15% | Not specified | Xtool X100 Pro2, Autel KM100E |

Performance Analysis

Shenzhen Xing Chen and Qingdao Everise stand out for high reorder rates and strong customization capabilities, indicating customer satisfaction and flexible production lines. Qingdao Everise achieves a 50% reorder rate—the highest among peers—suggesting effective post-sale support and product reliability. Chengdu Daobo offers premium-tier products like the Xhorse Dolphin XP005 series but reports a lower reorder rate, potentially reflecting higher entry cost points. Shenzhen Jindong leads in responsiveness (≤2h), making it suitable for urgent procurement cycles. For bulk buyers, prioritize suppliers with proven scalability (evidenced by revenue >US $150,000) and documented customization options. For specialized applications requiring firmware depth, evaluate product-specific vehicle compatibility lists before engagement.

FAQs

How to verify key cutter and programmer supplier reliability?

Cross-check on-time delivery records and response times via platform analytics. Request sample units to test build quality, software interface responsiveness, and accuracy of key cuts. Validate firmware update policies and check for active technical support channels.

What is the typical minimum order quantity (MOQ)?

MOQ varies: most programmers require only 1 unit, while automatic CNC key cutters often have MOQs of 2 sets. Some suppliers offer single-piece trials at slightly elevated pricing.

Are customization options available for branding and packaging?

Yes, multiple suppliers—including Shenzhen Xing Chen and Qingdao Everise—offer comprehensive customization for color, logo, packaging, labels, and even blade specifications. Confirm tooling requirements and setup fees prior to ordering.

What are common lead times for production and shipping?

Standard production lead time ranges from 7–15 days. Air freight adds 5–10 days globally; sea freight takes 25–40 days depending on destination. Expedited processing may be available for urgent orders.

Do suppliers provide technical documentation and after-sales support?

Reputable suppliers supply user manuals, firmware update guides, and diagnostic flowcharts. Post-purchase support varies—verify availability of multilingual assistance and remote troubleshooting services before finalizing contracts.