Key Cutting And Programming Machine Producer

Top sponsor listing

Top sponsor listing

About key cutting and programming machine producer

Where to Find Key Cutting and Programming Machine Producers?

China remains the central hub for key cutting and programming machine manufacturing, with Shenzhen and Guangdong emerging as core production clusters. These regions host vertically integrated supply chains that combine precision machining, electronic control systems, and software development under one ecosystem. Shenzhen's specialization in automotive electronics enables rapid prototyping and firmware integration, while Guangdong’s industrial infrastructure supports high-volume production of mechanical components such as clamping jaws, cutting wheels, and motor assemblies.

The concentration of component suppliers—ranging from servo motors to immobilizer chip programmers—within 50km radii reduces logistics overhead and accelerates assembly cycles. This proximity allows producers to maintain lean inventories while offering scalable output, typically achieving lead times of 15–30 days for standard orders. Buyers benefit from localized sourcing of critical materials like hardened steel blades, ABS plastic housings, and PCB modules, contributing to a 20–25% cost advantage over non-Asian manufacturers. The region also supports flexible order structures, accommodating both bulk shipments and low-volume customized configurations.

How to Choose Key Cutting and Programming Machine Producers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international standards such as CE for European market access and RoHS compliance for hazardous substance restrictions. While ISO 9001 certification is not universally declared in available data, prioritize suppliers who provide documented quality control procedures, especially for electronic calibration and software validation processes critical to key programming accuracy.

Production and Customization Capability

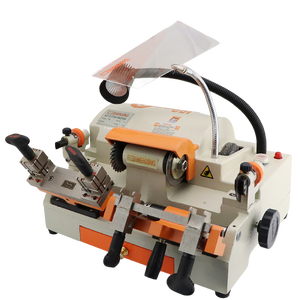

Assess capacity based on demonstrated product range and customization options. Leading producers offer configurable features including:

- Key blank compatibility (e.g., Toyota G chips, HU66, ID48/ID49)

- Software-enabled immobilizer programming for vehicle makes (BMW, Mercedes, Ford, etc.)

- Hardware modifications: color variants, labeling, packaging, and logo branding

- Adaptor kits for motorcycle, heavy-duty truck, and transponder key applications

Cross-reference customization claims with actual product listings and verify whether firmware updates are supported post-sale.

Transaction Reliability Metrics

Use performance indicators to assess dependability:

- On-time delivery rates ≥99% indicate robust production planning

- Response times ≤3 hours reflect dedicated customer support infrastructure

- Reorder rates above 25% suggest strong client retention and product reliability

- Online revenue exceeding US $300,000 annually signals established market presence

Suppliers with multispecialty verification status often demonstrate broader compliance frameworks and more structured export operations.

What Are the Top Key Cutting and Programming Machine Producers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Topbest Technology Co., Limited | Shenzhen, CN | Key Cutting Machines, Immobilizer Programmers, Car Key Cloning Tools | 100.0% | ≤3h | 27% | US $320,000+ | Color, material, logo, packaging, label, model, vehicle key types | Multispecialty Supplier |

| Shenzhen Topbest Technology Co., Limited | Shenzhen, CN | Manual/Automatic Key Cutters, Xhorse-Compatible Devices | 99.0% | ≤3h | 32% | US $420,000+ | Car door lock, motorcycle key, size, graphic, packaging | Multispecialty Supplier |

| Shenzhen Lenkor Technology Development Co., Ltd. | Shenzhen, CN | Diagnostic Tools, Key Programmers, TPMS | 90.0% | ≤7h | 17% | US $790,000+ | Activation card, adaptor, cloning function, label, size, logo | Multispecialty Supplier |

| Guangdong Yingjing Trading Co., Ltd. | Guangdong, CN | Locksmith Tools, Key Cutting & Programming Systems | 95.0% | ≤1h | <15% | US $30,000+ | Limited customization data available | Not specified |

| Foshan City Wenxing Machinery Co., Ltd. | Foshan, CN | Automatic Key Duplicators, Vertical Cutting Machines | 100.0% | ≤25h | Not available | Not available | No explicit customization noted | Not specified |

Performance Analysis

Shenzhen-based producers dominate in responsiveness and customization depth, with two Topbest Technology entities demonstrating 99–100% on-time delivery and reorder rates exceeding 27%. Their combined focus on hardware versatility and software integration positions them as preferred partners for distributors requiring branded or region-specific adaptations. Despite lower online revenue visibility, Foshan City Wenxing Machinery achieves perfect delivery performance, suggesting disciplined production scheduling, though limited response metrics may affect service agility.

Lenkor Technology stands out for highest reported online revenue (US $790,000+), indicating extensive market reach, but its 90% on-time rate warrants closer scrutiny of fulfillment consistency. Guangdong Yingjing offers the fastest average response time (≤1h), beneficial for urgent procurement cycles, though its sub-15% reorder rate suggests potential gaps in long-term customer satisfaction. For mission-critical deployments, prioritize suppliers with verifiable after-sales support, firmware update policies, and compatibility testing documentation.

FAQs

How to verify key cutting machine producer reliability?

Cross-check declared delivery performance against transaction histories where available. Request evidence of quality control protocols, particularly for electronic calibration and transponder programming accuracy. Evaluate supplier responsiveness through direct inquiry and assess technical support depth by requesting specifications for immobilizer compatibility and update mechanisms.

What is the typical minimum order quantity (MOQ)?

MOQ varies by model and automation level: manual machines start at 1–2 pieces, while automated systems require 3–5 sets. High-end models such as Xhorse-compatible units often have single-unit MOQs due to higher unit value.

Do producers support OEM/ODM services?

Yes, multiple suppliers explicitly list customization options for color, logo, packaging, and labeling. Some offer adaptors and software interface modifications. Confirm tooling costs and NRE (non-recurring engineering) fees before initiating design collaboration.

What are common payment and shipping terms?

Standard payment methods include T/T and Alibaba Trade Assurance. Shipping is typically FOB Shenzhen or Guangzhou, with air freight recommended for sample units (7–10 days globally) and sea freight for container loads (25–35 days). Confirm voltage compatibility (110V/220V) and inclusion of power adaptors.

Can I request a sample before bulk ordering?

Most producers allow sample purchases, with prices reflecting near full-cost recovery. Sample lead times range from 5–15 days depending on configuration complexity. Budget for additional costs related to express shipping and import duties during evaluation phases.