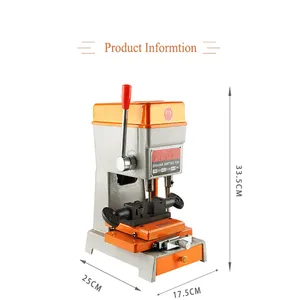

Key Machine Maker Automatic Key Cutting Vendor

1/25

1/25

0

0

1/3

1/3

1/24

1/24

1/3

1/3

1/3

1/3

1/12

1/12

0

0

0

0

1/21

1/21

1/3

1/3

1/7

1/7

0

0

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

About key machine maker automatic key cutting vendor

Where to Find Key Machine Maker Automatic Key Cutting Vendors?

China remains the central hub for automatic key cutting machine manufacturing, with concentrated supplier clusters in Guangdong and Henan provinces. These regions host vertically integrated production ecosystems that combine precision engineering, electronics assembly, and software integration under one supply chain. Shenzhen, within Guangdong, is particularly notable for its specialization in high-tech locksmith equipment, leveraging proximity to semiconductor and PCB suppliers to streamline production of CNC-based key duplication systems.

The industrial clusters enable rapid prototyping and scalable output, supported by mature logistics networks for global export. Suppliers benefit from localized access to aluminum die-casting, stepper motor components, and touch-screen interface modules, reducing material lead times by 20–30% compared to offshore alternatives. Buyers can expect standard order fulfillment within 15–30 days, with many vendors offering modular designs that support both standalone and vending-integrated deployments. Cost efficiencies from regional sourcing allow competitive pricing, especially for mid-to-high volume orders.

How to Choose Key Machine Maker Automatic Key Cutting Vendors?

Selecting a reliable vendor requires due diligence across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify compatibility with international key profiles (e.g., automotive, residential, commercial). Machines must support adjustable clamping mechanisms and dual-side milling for asymmetric keys. While formal certifications like CE or RoHS are not universally declared in listings, prioritize vendors who provide firmware update logs and database version documentation—critical for long-term usability in locksmith operations.

Production and Customization Capacity

Assess vendor capability through the following indicators:

- In-house CNC machining and electronic control board assembly

- Firmware customization options (language, UI layout, diagnostic functions)

- Physical customization: color, branding, packaging, and label design

Cross-reference product listings with reorder rates and response times as proxies for after-sales reliability and service responsiveness.

Procurement Safeguards

Utilize secure payment methods such as escrow services to mitigate risk. Request sample units to evaluate build quality, software interface stability, and cutting accuracy before bulk ordering. Confirm whether spare parts (e.g., cutting wheels, collets) and technical support are available post-purchase. Analyze online revenue metrics and delivery performance—vendors with consistent on-time delivery (>96%) and response times under 4 hours demonstrate stronger operational discipline.

What Are the Best Key Machine Maker Automatic Key Cutting Vendors?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Gongyi City Jingying Machinery Manufacturing Factory | Henan, CN | US $400,000+ | 96% | 26% | ≤4h | Color, material, size, logo, packaging, graphic | 1 set | $980–1,950 |

| Shenzhen Topbest Technology Co., Limited | Guangdong, CN | US $740,000+ | 100%/99% | 29%/32% | ≤3h | Color, language, model, PCB, key shell, packaging, car parts | 1–2 pieces | $115.50–2,198 |

| Guangdong Yingjing Trading Co., Ltd. | Guangdong, CN | US $30,000+ | 96% | <15% | ≤1h | Limited (implied via product variants) | 1–5 sets | $78–999 |

| Shenzhen Hua Shi Locksmith Technology Co. Ltd. | Guangdong, CN | US $80,000+ | 97% | <15% | ≤4h | Branding and model-specific configurations | 1–3 sets | $334.50–9,500 |

Performance Analysis

Shenzhen Topbest Technology stands out with two verified entities achieving near-perfect on-time delivery (100% and 99%) and strong reorder rates (29% and 32%), indicating consistent customer satisfaction. The company offers broad customization across hardware, firmware, and branding, making it suitable for distributors seeking differentiated products. Gongyi City Jingying targets mid-tier professional users with stable pricing and moderate customization, backed by higher annual revenue visibility. Guangdong Yingjing presents an entry-level option with aggressive pricing on basic models but shows lower repeat business, suggesting potential limitations in after-sales support. Shenzhen Hua Shi distinguishes itself with ultra-premium vending-integrated systems priced at $9,500/set, targeting automated retail applications rather than traditional locksmith channels.

FAQs

How to verify automatic key cutting machine supplier reliability?

Evaluate on-time delivery history, response time consistency, and verifiable online transaction volume. Request firmware demonstration videos or remote access trials. Check for inclusion of essential accessories (chucks, calibration tools, user manuals) and confirm availability of technical documentation in required languages.

What is the typical sampling timeline?

Standard sample processing takes 7–14 days, depending on customization level. Shipping via express courier adds 5–10 days internationally. Complex firmware modifications may extend lead time to 21 days. Some vendors offer expedited service for urgent requests at additional cost.

Can these machines cut transponder or laser-cut keys?

Yes, advanced models listed support side-milling for laser-cut automotive keys and include alignment guides for HU101, HU66, and similar profiles. However, transponder programming requires separate electronic modules—confirm whether the vendor supplies integrated RFID/T5 cloning functionality or if it must be added externally.

Do suppliers offer free samples?

Free samples are uncommon due to high unit value. Most vendors charge full or partial fees, which may be credited toward future bulk orders (typically 5+ units). Sample costs often range between 30–70% of the unit price.

How to initiate customization requests?

Submit detailed specifications including preferred housing color, display language, logo placement, packaging format, and any required mechanical adjustments. Reputable suppliers respond with updated renderings within 48–72 hours and can deploy modified units within 2–3 weeks after approval.