Lab Tables

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/2

1/2

1/15

1/15

1/31

1/31

CN

CN

1/31

1/31

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/39

1/39

1/43

1/43

1/3

1/3

1/31

1/31

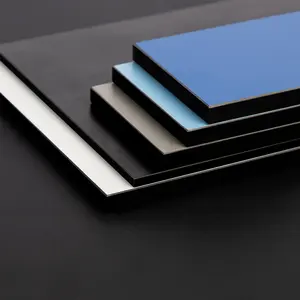

About lab tables

Where to Find Lab Tables Suppliers?

China remains the central hub for lab tables manufacturing, with key industrial clusters in Guangdong, Jiangsu, and Zhejiang provinces driving production efficiency and export capacity. Guangdong’s Pearl River Delta region hosts a dense network of metalworking and furniture manufacturers, enabling rapid prototyping and high-volume output. Jiangsu and Zhejiang offer integrated supply chains for stainless steel, epoxy resin, and phenolic resin components—critical materials in laboratory-grade work surfaces.

These regions benefit from vertically aligned production ecosystems, where raw material processing, CNC fabrication, powder coating, and final assembly occur within tightly coordinated zones. This integration supports lead times averaging 25–40 days for standard orders, with cost advantages of 20–35% over European and North American producers due to lower overhead and localized sourcing. Buyers gain access to scalable operations capable of fulfilling bulk institutional contracts or specialized configurations for research, pharmaceutical, or educational facilities.

How to Choose Lab Tables Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product compliance:

Material & Construction Standards

Confirm use of chemically resistant surface materials such as epoxy resin (minimum 19mm thickness), phenolic resin, or 304/316 stainless steel. Frame construction should utilize powder-coated steel or aluminum with anti-corrosion treatment. Demand test reports validating resistance to common reagents (e.g., sulfuric acid, sodium hydroxide) per ASTM D543 or ISO 175 standards.

Quality Management Systems

Require ISO 9001 certification as baseline quality assurance. For laboratories operating under regulated environments (GLP, GMP), verify compliance with ANSI/BIFMA X5.5 laboratory furniture standards. CE marking is essential for EU market entry, indicating adherence to safety and environmental directives.

Production Capacity Verification

Assess operational scale through objective metrics:

- Minimum factory area of 3,000m² to support batch production

- In-house CNC cutting, welding, and surface lamination capabilities

- Dedicated R&D or engineering team for custom configurations

Cross-reference facility size with monthly output capacity (target: 500+ units/month) and on-time delivery performance (benchmark: ≥97%).

Customization & Compliance Documentation

Evaluate technical responsiveness by submitting detailed specifications including load capacity (typically 500–1,000 kg), height adjustability, utility integration (gas, water, electrical), and seismic certification requirements. Reputable suppliers provide CAD drawings within 72 hours and maintain traceability records for material sourcing and finishing processes.

What Are the Best Lab Tables Suppliers?

No supplier data available for analysis.

FAQs

How to verify lab tables supplier reliability?

Validate certifications through issuing bodies and request third-party audit summaries covering production workflows, material traceability, and quality control checkpoints. Prioritize suppliers with documented experience exporting to North America or Europe, as these markets enforce stringent product safety and documentation requirements.

What is the typical MOQ and lead time for lab tables?

Standard minimum order quantities range from 5–20 units, with lead times of 25–40 days post-design approval. Expedited production (18–25 days) is available from larger manufacturers for urgent institutional projects, often at a 10–15% premium.

Can lab tables be customized for specific lab layouts?

Yes, most established manufacturers support full customization including dimensions, modular connectivity, underframe storage, and utility service integration. Provide floor plans and technical schematics to enable accurate quoting and layout simulation.

Do suppliers offer sample units?

Sample policies vary. Some suppliers provide single-unit samples at full cost, which may be credited toward future bulk orders. Free samples are typically reserved for contracts exceeding 50 units. Allow 15–25 days for sample production and 7–10 days for international air freight delivery.

What are common packaging and shipping methods?

Lab tables are typically flat-packed with edge protection and moisture-resistant wrapping to prevent transit damage. Full container loads (FCL) via sea freight are standard for bulk shipments. Confirm FOB or CIF terms and ensure packaging meets ISPM 15 requirements for wooden components.