Label Machine Staples

HK

HK

1/22

1/22

1/15

1/15

1/25

1/25

1/25

1/25

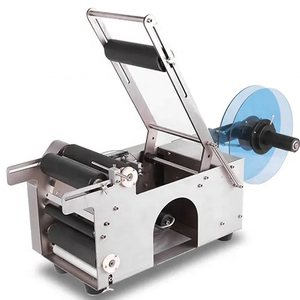

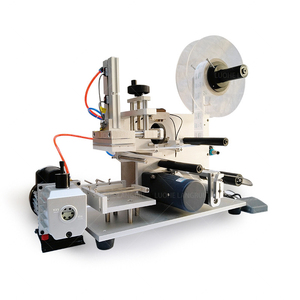

About label machine staples

Where to Find Label Machine Staples Suppliers?

China remains the central hub for label machine staples manufacturing, with key production clusters in Jiangsu, Anhui, and Guangdong provinces. These regions host vertically integrated supply chains that combine precision metalworking, plastic molding, and automated assembly under one ecosystem. Kunshan in Jiangsu specializes in high-speed elastic fastener systems, leveraging proximity to Shanghai’s logistics network for rapid export processing. Hefei in Anhui has emerged as a center for compact labeling applicators, supported by regional expertise in cable and packaging machinery components.

The industrial concentration enables economies of scale, with many suppliers operating end-to-end production lines—from raw material extrusion to finished product testing. This integration reduces component lead times by 20–30% compared to fragmented sourcing models. Buyers benefit from consolidated manufacturing zones where tooling, calibration, and quality inspection occur within localized facilities, ensuring consistent output for both standard and custom configurations. Typical advantages include MOQ flexibility (as low as 1 set), competitive pricing due to lower labor and material costs, and scalable production capacity for bulk orders.

How to Choose Label Machine Staples Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance and Product Range

Verify that suppliers offer equipment compatible with industry-standard staple types (plastic pin, elastic fasteners, hybrid tags) and labeling methods (manual, semi-automatic, full-auto). Confirm compatibility with substrate materials such as woven labels, adhesive stickers, or heat-shrink sleeves. For international buyers, ensure machines support voltage standards (e.g., 110V/220V) and carry relevant safety certifications (CE, RoHS) if required for market entry.

Production Capability Verification

Assess core manufacturing infrastructure through available metrics:

- Facility size and automation level—larger operations often indicate scalability

- In-house R&D capacity for customization (e.g., adjustable needle distance, multi-head stapling)

- Integration of CNC machining, injection molding, and final assembly lines

Cross-reference on-time delivery rates (target ≥95%) and response times (ideally ≤3 hours) as proxies for operational efficiency.

Transaction and Quality Safeguards

Prioritize suppliers with documented quality control processes and third-party verification mechanisms. Evaluate reorder rates as an indicator of customer satisfaction—rates below 15% may suggest niche focus or limited after-sales support. Request sample units to test staple feed reliability, cycle speed, and durability under continuous operation. Use secure payment terms such as escrow services until product acceptance is confirmed.

What Are the Best Label Machine Staples Suppliers?

| Company Name | Location | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| BOOSTER (HK) TRADING CO., LIMITED | Hong Kong, CN | Elastic fasteners, plastic tag pins, auto labeling systems | $1,229–$1,788 | 1–2 sets | 100% | ≤2h | <15% | US $500+ |

| Hefei Better Technology Co., Ltd. | Anhui, CN | Handheld labelers, manual applicators, portable systems | $30–$1,600 | 1 set | 100% | ≤3h | <15% | US $40,000+ |

| Kunshan Yuanhan Electronic Equipment Co., Ltd. | Jiangsu, CN | Manual sticker machines, hybrid staple attachers, automatic pasting systems | $57–$15,000 | 1 set | 83% | ≤8h | <15% | US $10,000+ |

| Aman Industry Co., Ltd. | Zhejiang, CN | Semi-automatic, high-speed sticker printers, bottle labeling systems | $480–$4,500 | 1 set | 100% | ≤9h | 100% | US $90,000+ |

| Lanhai Finenorm Coding Co., Ltd. | Shandong, CN | Automatic flat/round bottle labelers, box-top applicators, dispensers | $950–$1,690 | 1 acre* | 100% | ≤2h | 24% | US $70,000+ |

Performance Analysis

BOOSTER and Hefei Better Technology stand out for responsiveness (≤2–3h) and consistent on-time fulfillment, making them suitable for urgent procurement cycles. Hefei Better offers the widest accessibility with handheld models priced from $30, ideal for small-scale operations. Aman Industry demonstrates strong customer retention (100% reorder rate), suggesting robust post-sale service despite slower response times. Lanhai Finenorm maintains high delivery performance with standardized automatic systems but lists “1 acre” as minimum order—a likely data anomaly requiring clarification during inquiry. Kunshan Yuanhan provides broad product diversity, including industrial-grade cut-and-fold machinery, though its 83% on-time rate warrants closer shipment monitoring.

FAQs

How to verify label machine staples supplier reliability?

Cross-check stated capabilities with verifiable data: request facility videos, production logs, and client references. Confirm compliance with ISO 9001 or equivalent quality management systems. Analyze transaction history indicators such as on-time delivery rate, response time, and online revenue volume as proxies for operational stability.

What is the typical lead time for sample orders?

Standard samples are typically shipped within 7–15 days after confirmation. Complex configurations involving custom molds or electrical adaptations may require 20–30 days. Air freight adds 5–10 days for international delivery.

Do suppliers support customization?

Yes, most suppliers listed offer customization options including color, material (ABS, PP, metal alloys), logo imprinting, packaging, and graphic interface design. High-end models allow adjustments in staple pitch, labeling speed, and conveyor integration. Submit detailed technical drawings or specifications to initiate engineering review.

Are free samples available?

Free samples are uncommon for capital equipment. Suppliers typically charge a fee covering production and shipping, which may be credited toward future bulk orders. Expect sample costs ranging from 30% to 100% of unit price depending on complexity.

What are common MOQ and pricing structures?

MOQs vary from 1 set for standard models to higher volumes for customized builds. Prices range from $30 for handheld manual applicators to over $15,000 for fully automated systems. Bulk discounts are typically offered at 10+ units, with negotiated terms improving at 50+ units.