Label Maker Clear Labels

1/8

1/8

1/18

1/18

1/10

1/10

1/10

1/10

1/25

1/25

About label maker clear labels

Where to Find Label Maker Clear Labels Suppliers?

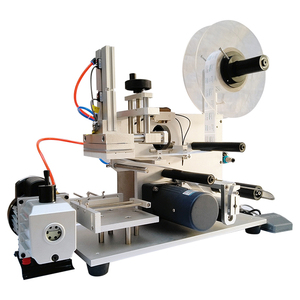

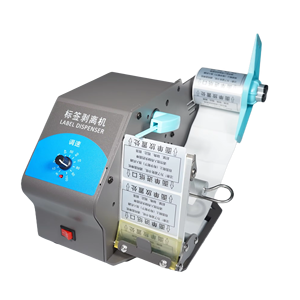

China remains the central hub for manufacturing equipment and consumables related to label maker clear labels, with key production clusters in Guangdong, Jiangsu, and Shanghai. These regions host vertically integrated supply chains that combine precision engineering for labeling machinery with advanced film and adhesive material processing. Guangdong specializes in high-speed dispensing and peeling machines, leveraging proximity to electronics and packaging industries for rapid component sourcing. Jiangsu’s industrial base focuses on automated flat and round surface labeling systems, often integrated into larger production lines for cosmetics, food, and beverage sectors.

The concentration of suppliers in these zones enables efficient coordination between machine builders and material producers, reducing development lead times by up to 30%. Buyers benefit from localized access to complementary technologies such as thermal printers, rewinding systems, and custom film extrusion. This ecosystem supports both standalone label dispensers and fully automated inline solutions, with typical delivery windows ranging from 15–30 days for standard units. Cost advantages are significant, with production expenses averaging 20–40% below Western counterparts due to optimized labor and logistics networks.

How to Choose Label Maker Clear Labels Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Material Expertise

Verify the supplier’s capability in handling transparent adhesive films, particularly polyester (PET) and polypropylene (PP) substrates used in clear label applications. For printing compatibility, confirm support for inkjet or thermal transfer processes. Suppliers offering Memjet-compatible printable labels demonstrate alignment with modern digital labeling workflows.

Production Capacity and Scalability

Assess infrastructure indicators such as factory size, automation level, and monthly output capacity. Key benchmarks include:

- Minimum facility area of 2,000m² for equipment manufacturers

- In-house design and assembly lines for labeling machines

- Dedicated R&D teams for customization and integration projects

- Monthly production capacity exceeding 100 units for machine builders or 500,000+ sheets for label stock producers

Cross-reference online revenue metrics and reorder rates—suppliers with reorder rates above 20% and response times under 4 hours typically exhibit stronger service consistency.

Quality Assurance and Compliance

While formal ISO 9001 certification is not universally declared in available data, prioritize suppliers with documented quality control procedures, especially for adhesive consistency, die-cut accuracy, and machine calibration. On-time delivery rates above 90% serve as a proxy for internal process reliability. For export compliance, ensure product documentation includes CE marking where applicable, particularly for electrical components in automatic dispensers.

Transaction Security and Sampling Protocols

Utilize secure payment mechanisms such as escrow services when placing initial orders. Request physical samples before bulk procurement to evaluate label clarity, edge adhesion, and dispenser feed performance. Most suppliers offer sample units at 1–2x unit cost, with lead times of 7–14 days. Confirm return policies and defect resolution procedures prior to order placement.

What Are the Best Label Maker Clear Labels Suppliers?

| Company Name | Main Products | Price Range (Units) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Jiangsu Yundongxin Machinery Equipment Co., Ltd. | Labeling Machines, Filling & Water Treatment Equipment | $4,200–$5,000 | 1 piece | - | ≤6h | 50% | US $9,000+ |

| Guangzhou Bishixi Technology Co., Ltd. | Label Dispensers, Thermal Printers, Sealing Machines | $96–$160 | 1 unit | 100% | ≤2h | <15% | US $90,000+ |

| Shanghai Yunsai Technology Co., Ltd. | Packaging Labels, Adhesive Films, Photo Paper | $0.12–$0.15/sheet | 5,000 sheets | 89% | ≤3h | 21% | US $60,000+ |

| Shenzhen Dinghao Paper Product Packaging Corp. Ltd. | Packaging Labels, Printing, Stickers, Hangtags | $0.01–$0.64/unit | 100–1,000 pieces | 89% | ≤5h | 26% | US $50,000+ |

| Guangzhou Chaoxian Packing Machine Co., Ltd. | Automatic Labeling Systems, Custom Machinery | $1,695–$10,285/set | 1 set | 94% | ≤4h | 20% | US $150,000+ |

Performance Analysis

Guangzhou Bishixi stands out for responsiveness (≤2h) and perfect on-time delivery, making it ideal for time-sensitive procurement of label dispensers. Despite a lower reorder rate, its high online revenue suggests strong market penetration. Guangzhou Chaoxian leads in transaction volume (US $150,000+), indicating scalability for large-scale automated labeling systems. Jiangsu Yundongxin exhibits the highest reorder rate (50%), signaling strong customer retention, though response time is slower. Shanghai Yunsai and Shenzhen Dinghao specialize in consumables, offering competitive pricing for printable clear labels with MOQs starting at 5,000 sheets. Buyers seeking integrated hardware-consumable solutions should evaluate cross-supplier compatibility, particularly between dispenser mechanisms and label roll specifications (core size, tension, backing paper).

FAQs

What is the typical MOQ for label maker clear labels?

For labeling machines, MOQ is typically 1 unit or set. For clear label stock, MOQ ranges from 100 pieces for custom designs to 5,000 sheets for standardized printable formats. Roll-fed labels often require minimum runs of 1,000 units.

How long does production and shipping take?

Standard machine orders take 15–25 days for production and 7–14 days for international air freight. Label stock production averages 7–15 days, with sea freight adding 20–35 days for overseas delivery. Express shipping options reduce transit time to 3–7 days at higher cost.

Can suppliers customize label makers for specific applications?

Yes, most equipment suppliers offer customization for bottle shape, label size, speed, and integration with conveyor systems. Technical drawings and application requirements must be provided upfront. Prototype development typically takes 2–4 weeks.

Are clear labels compatible with inkjet and laser printers?

Printable clear labels from suppliers like Shanghai Yunsai are engineered for inkjet systems, including Memjet platforms. Laser compatibility varies—verify coating specifications to prevent melting or toner adhesion issues.

What payment terms are common among suppliers?

Common terms include 30% deposit with balance before shipment. Escrow services are recommended for first-time transactions. Some suppliers accept letters of credit for large orders. Sample payments are usually required upfront.