Labeling Machine Supplier

Top sponsor listing

Top sponsor listing

About labeling machine supplier

Where to Find Labeling Machine Suppliers?

China remains the global epicenter for labeling machine manufacturing, with key industrial hubs concentrated in Guangdong and Zhejiang provinces. These regions host vertically integrated supply chains that streamline production from component casting to final assembly. Guangdong, particularly Dongguan and Foshan, is home to over 70% of China’s packaging automation suppliers, supported by advanced CNC machining clusters and rapid prototyping facilities. Wenzhou in Zhejiang specializes in cost-effective semi-automatic systems, leveraging localized access to servo motors, pneumatic components, and sensor modules.

The clustering effect enables tight coordination between machinery OEMs and parts suppliers within a 30–50 km radius, reducing material lead times by up to 40%. Buyers benefit from scalable production capacity, with standard lead times averaging 20–35 days for non-customized units. Localized sourcing also contributes to 18–25% lower unit costs compared to equivalent European or North American manufacturers, making these zones ideal for both low-volume trials and high-volume procurement.

How to Choose Labeling Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Capabilities

Verify ISO 9001 certification as a baseline for quality management systems. For export-bound equipment, confirm CE marking compliance to meet EU safety directives. Assess machine specifications against application needs—round bottle labeling systems typically require diameter adaptability (20–150mm), while flat-surface applicators must support label widths up to 120mm. Demand performance data on labeling accuracy (±0.5mm tolerance) and throughput (units per minute).

Production Infrastructure Assessment

Prioritize suppliers with minimum 3,000m² factory space and in-house engineering teams capable of customization. Key capabilities include:

- Integrated design-to-production workflows using CAD/CAM software

- In-house fabrication of critical subsystems (e.g., label dispensing mechanisms, conveyor integration)

- Capacity for batch testing under real-world conditions

Cross-reference facility size with online transaction volume and on-time delivery rates (target ≥95%) to assess scalability and reliability.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based disbursement tied to production verification. Request sample units before full orders to evaluate build quality and labeling consistency. Confirm post-delivery support availability, including technical documentation, spare parts inventory, and remote troubleshooting. Analyze reorder rates and response times as proxies for customer satisfaction and service responsiveness.

What Are the Best Labeling Machine Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Guangdong Feibin Machinery Group Co., Ltd. | Custom Manufacturer | Labeling Machines, Filling Machines, Multi-Function Packaging Systems | 98% | ≤3h | 24% | US $1.7M+ | Yes (material, size, logo, sensor, direction) | 1 set |

| Dongguan BanMo Machinery Co., Ltd. | Multispecialty Supplier | Semi-Automatic & Compact Labeling Systems | 100% | ≤2h | <15% | US $370K+ | Yes (color, material, size, packaging, graphics) | 1 piece |

| Dongguan Sammi Packing Machine Co., Ltd. | Multispecialty Supplier | Semi-Automatic & Automatic Bottle/Flat Labelers | 89% | ≤2h | <15% | US $370K+ | Yes (diameter, material, label width/length) | 1 set |

| Dongguan Auchan Automation Equipment Technology Co., Ltd. | Not Specified | Desktop, Semi-Automatic, Full-Automatic Labelers | 64% | ≤4h | <15% | US $40K+ | Limited (implied via product range) | 1 set |

| Wenzhou Likang Machinery Co., Ltd. | Not Specified | Manual, Semi-Automatic Round Bottle Labelers | 57% | ≤6h | <15% | US $10K+ | No explicit mention | 1 piece |

Performance Analysis

Guangdong Feibin stands out with the highest revenue and strongest delivery performance (98%), coupled with a notable 24% reorder rate—indicating robust customer retention and system reliability. Dongguan BanMo achieves perfect on-time delivery and sub-2-hour response times, making it ideal for time-sensitive procurement despite a lower reorder rate. Sammi Packing demonstrates strong technical responsiveness but slightly lower fulfillment consistency at 89%. Suppliers based in Dongguan exhibit superior communication efficiency, with 60% responding within two hours. For high-volume contracts, prioritize suppliers with verified customization workflows and proven export experience. Conduct virtual factory audits to validate production lines before committing to large orders.

FAQs

How to verify labeling machine supplier reliability?

Cross-check certifications (ISO, CE) with official registries. Review transaction history metrics such as on-time delivery rate, response speed, and verified sales volume. Request references or third-party inspection reports if available. Evaluate product listings for detailed technical specifications and consistency in branding.

What is the typical MOQ and pricing range?

Minimum order quantities start at 1 piece for manual models and 1 set for automated systems. Pricing varies significantly: manual labelers begin at $35/unit, semi-automatic units range from $200–$1,200, and fully automatic systems exceed $5,500. Volume discounts are commonly offered beyond 5–10 units.

Can labeling machines be customized?

Yes, leading suppliers offer customization in labeling direction, sensor type, material compatibility, size configuration, and branding elements. Customization lead time typically adds 7–14 days to standard production schedules. Provide detailed technical drawings or use cases to expedite quoting.

Do suppliers provide samples?

Sample availability depends on model complexity. Basic manual units may be provided at reduced cost, while automated systems often require full payment for initial units unless part of a confirmed bulk order. Allow 10–20 days for sample production and international shipping.

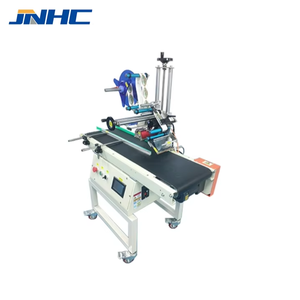

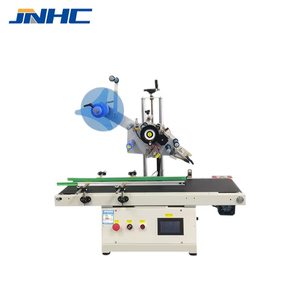

What are common labeling machine types available?

Available configurations include manual hand-press, semi-automatic round bottle, flat surface automatic, desktop electric, and multi-head drum labeling systems. Selection should align with container geometry, production speed, and integration requirements (standalone vs. inline).