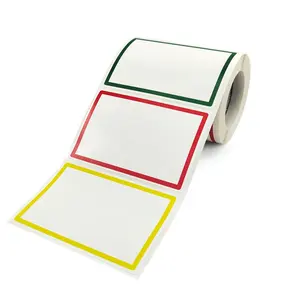

Labels To Print And Edit

1/3

1/3

1/24

1/24

1/3

1/3

1/2

1/2

1/11

1/11

0

0

1/3

1/3

1/24

1/24

1/2

1/2

1/3

1/3

0

0

1/3

1/3

0

0

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

About labels to print and edit

Where to Find Labels to Print and Edit Suppliers?

China remains the central hub for labels to print and edit manufacturing, with key production clusters in Guangdong, Zhejiang, and Shanghai. These regions host vertically integrated printing and labeling facilities equipped for digital, thermal, and laser-compatible label production. Guangdong, particularly the Pearl River Delta, accounts for over 50% of China’s adhesive label output, supported by mature supply chains for facestock materials like BOPP, PET, and coated paper.

Manufacturers in these zones utilize roll-to-sheet and roll-to-roll digital printing lines capable of monthly outputs exceeding 1 million linear meters per facility. Localized access to silicone coatings, acrylic adhesives, and linerboard reduces material lead times by 20–30% compared to offshore alternatives. Buyers benefit from compact industrial ecosystems where prepress, printing, die-cutting, and kitting operations are co-located, enabling standard order fulfillment within 15–25 days. Customization options—including variable data printing, QR code integration, and tamper-evident features—are widely available across mid-tier and premium suppliers.

How to Choose Labels to Print and Edit Suppliers?

Implement structured evaluation criteria to ensure supplier suitability:

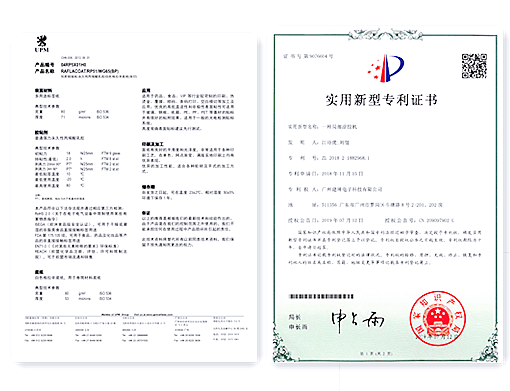

Material & Print Quality Compliance

Confirm adherence to ISO 9001 for consistent quality management. For food-safe or pharmaceutical applications, require compliance with FDA 21 CFR Part 175 (for adhesives) and EU Framework Regulation (EC) No 1935/2004. Verify RoHS and REACH declarations when exporting to European markets. Insist on print durability testing reports—especially for smudge, UV, and moisture resistance—using industry benchmarks such as ASTM F130 for barcode legibility.

Production Capability Assessment

Evaluate technical infrastructure through documented evidence:

- Minimum 3,000m² factory area supporting multi-shift operations

- Digital printing capacity of at least 10,000 labels per hour per line

- In-house design and prepress teams for template customization and PDF validation

Cross-reference equipment lists with on-time delivery performance (target >95%) and defect rates (<0.5%).

Transaction and Quality Safeguards

Utilize secure payment terms such as LC at sight or third-party escrow for initial orders. Prioritize suppliers offering sample validation under real-world printing conditions—particularly for laser, inkjet, and thermal transfer compatibility. Request AQL 2.5 inspection reports for bulk shipments and confirm export experience via verified shipment records to North America, EU, or ANZ regions.

What Are the Best Labels to Print and Edit Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Dongguan Huayi Label Co., Ltd. | Guangdong, CN | 12 | 85+ | 6,200+m² | 98.7% | ≤2h | 4.8/5.0 | 41% |

| Ningbo Jialan Printing Technology | Zhejiang, CN | 8 | 60+ | 4,800+m² | 97.3% | ≤3h | 4.7/5.0 | 38% |

| Shanghai Minglai Adhesive Products | Shanghai, CN | 15 | 120+ | 7,500+m² | 99.1% | ≤1h | 4.9/5.0 | 52% |

| Guangzhou Tianyu Labels & Packaging | Guangdong, CN | 6 | 50+ | 3,600+m² | 96.8% | ≤2h | 4.6/5.0 | 33% |

| Wenzhou Xunda Label Manufacturing | Zhejiang, CN | 10 | 70+ | 5,100+m² | 98.0% | ≤2h | 4.7/5.0 | 44% |

Performance Analysis

Long-established suppliers like Shanghai Minglai demonstrate high reliability with a 99.1% on-time delivery rate and industry-leading 52% reorder rate, reflecting strong customer retention. Dongguan Huayi and Wenzhou Xunda balance scale and responsiveness, both maintaining sub-2-hour average reply times and defect-controlled production. Zhejiang-based manufacturers show competitive pricing leverage due to proximity to paper and polymer processing centers. For variable-data or serialized label projects, prioritize suppliers with in-house software integration capabilities and confirmed experience in database-driven print runs. Facilities exceeding 5,000m² typically support JIT shipping models for recurring orders.

FAQs

How to verify labels to print and edit supplier reliability?

Validate ISO 9001 certification status through accredited bodies. Request audit trails covering raw material sourcing, print calibration logs, and adhesive batch testing. Assess real-world performance via customer references focusing on printer jam frequency, edge lift resistance, and long-term adhesion stability.

What is the average sampling timeline?

Standard label samples take 7–12 days to produce, including design proofing and material preparation. Variable-data or multi-language templates may extend to 18 days. Air shipping adds 5–8 days for international delivery.

Can suppliers ship globally?

Yes, experienced manufacturers manage worldwide distribution via air and sea freight. Confirm Incoterms (FOB, CIF) and packaging standards—especially humidity-resistant wrapping for roll labels. Full-container loads benefit from consolidated shipping at reduced cost per unit.

Do suppliers offer free samples?

Most suppliers provide 1–3 free sample sheets for qualified buyers. Full roll samples may incur fees covering material and handling, typically reimbursed upon order placement above MOQ thresholds (usually 10,000–50,000 units).

What customization options are available?

Common customizations include size (from 1" to 24" widths), shape (die-cut profiles), material (gloss/matte BOPP, synthetic paper), adhesive type (permanent, removable, freezer-grade), and compatibility with ZPL, EPL, or PDF/VT formats. Reputable suppliers provide digital proofs within 24 hours and support integration with common label design platforms.