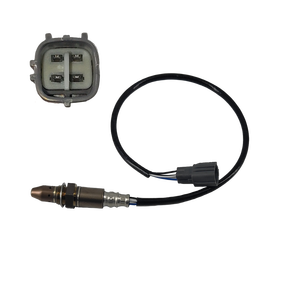

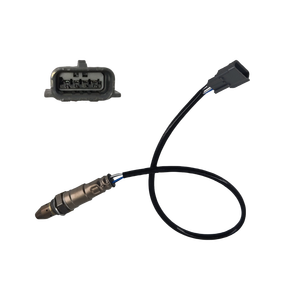

Lambda Sensor

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/24

1/24

1/3

1/3

1/3

1/3

1/17

1/17

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/23

1/23

1/3

1/3

1/3

1/3

About lambda sensor

Where to Find Lambda Sensor Suppliers?

China remains a dominant hub for lambda (oxygen) sensor manufacturing, with key production clusters in Guangdong and Hubei provinces driving export-oriented supply chains. Guangzhou-based suppliers leverage mature automotive parts ecosystems, integrating precision electronics, zirconia sensing elements, and stainless-steel housings within vertically aligned facilities. Wuhan and Shenzhen manufacturers specialize in high-volume OEM-equivalent sensors, utilizing automated assembly lines to maintain tight tolerances for exhaust gas measurement accuracy.

These industrial zones benefit from proximity to Tier 1 automotive component suppliers, reducing material lead times by 20–30%. Regional advantages include access to specialized ceramics processing, laser welding capabilities, and calibrated test benches simulating real-time exhaust conditions. Buyers can expect standard lead times of 15–30 days for batch orders, with MOQs typically ranging from 4 to 10 pieces per model. The concentration of engineering talent and testing infrastructure enables rapid prototyping and validation for vehicle-specific sensor variants.

How to Choose Lambda Sensor Suppliers?

Procurement decisions should be guided by technical, operational, and transactional verification protocols:

Technical Compliance & Quality Assurance

Confirm adherence to ISO 9001 standards as a baseline for quality management. For markets requiring regulatory compliance, ensure CE, RoHS, or E-mark certification documentation is available. Validate sensor performance specifications—such as response time (<100ms), operating temperature range (400–800°C), and lifespan (60,000–100,000 km)—against OEM benchmarks. Request test reports for signal stability under varying exhaust conditions.

Production and Customization Capacity

Assess supplier capability through the following indicators:

- In-house design and calibration systems for ZrO₂-based sensing elements

- Support for multi-wire configurations (2-wire to 5-wire) and thread sizes (M12, M18, etc.)

- Customization options for connector types, cable lengths, and heater circuit designs

Cross-reference product listings with reorder rates (target >20%) and on-time delivery performance (ideally ≥99%) to assess reliability and scalability.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with documented dispute resolution processes and transparent communication (response time ≤2 hours). Conduct sample testing to verify compatibility with engine control units (ECUs) and resistance to contamination from oil or coolant ingress before scaling procurement.

What Are the Best Lambda Sensor Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Sample MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Zhenhua Auto Part Trading Co., Ltd. | Guangdong, CN | Auto Sensors, Fuel Injectors, Ignition Coils | US $610,000+ | 99% | ≤2h | 50% | 10 pcs | $2.50–18.50 |

| Westbay Intelligent Technology (Shenzhen) Co., Ltd | Guangdong, CN | Auto Sensors (6,367) | US $110,000+ | 95% | ≤2h | 18% | 1 pc | $15.95–15.98 |

| Guangzhou Weiqi Auto Parts Co., Ltd. | Guangdong, CN | Auto Sensors (1,154), Fuel Pumps | US $240,000+ | 100% | ≤2h | 22% | N/A | N/A |

| Wuhan Zirconia Electronic Technology Co., Ltd. | Hubei, CN | Auto Sensors (694) | US $10,000+ | 100% | ≤2h | 20% | 4–10 pcs | $6–17.50 |

| Wuhan Zhongteng Powertrain System Co., Ltd. | Hubei, CN | Auto Sensors (202) | US $1,000+ | 100% | ≤3h | 25% | 5 pcs | $4.50–8.40 |

Performance Analysis

Guangzhou Zhenhua stands out with a 50% reorder rate and broad customization capacity, indicating strong customer retention and flexibility for private labeling or specification adjustments. Westbay in Shenzhen offers single-piece sampling and high listing volume, suitable for low-volume testing or niche applications. Wuhan-based suppliers provide cost-effective solutions with prices as low as $4.50, leveraging localized zirconia material sourcing. All top-tier suppliers maintain ≤2-hour response times and 100% on-time delivery records, critical for just-in-time inventory models. Buyers seeking high-volume consistency should prioritize suppliers with diversified product portfolios and verifiable quality control logs.

FAQs

How to verify lambda sensor supplier reliability?

Validate certifications through official registries and request audit trails covering raw material sourcing, calibration procedures, and final functional testing. Analyze customer feedback focusing on long-term sensor durability and ECU compatibility across different vehicle platforms.

What is the typical sampling timeline for lambda sensors?

Standard samples are shipped within 7–14 days after confirmation. Complex variants requiring custom connectors or heating elements may take up to 21 days. Air freight adds 5–10 days for international delivery.

Do suppliers support global shipping and customs clearance?

Yes, established exporters manage international logistics via air or sea freight. Confirm Incoterm preferences (FOB, CIF) and ensure packaging includes necessary compliance labels for destination markets.

Are free samples available for lambda sensors?

Free samples are rare; most suppliers charge a nominal fee recoverable against future bulk orders. Some offer discounted samples for buyers committing to minimum annual volumes.

How to initiate custom lambda sensor development?

Submit detailed technical requirements including vehicle make/model/year, OBD-II protocol, wire configuration, thread dimensions, and desired lifespan. Leading suppliers provide CAD drawings and prototype units within 2–3 weeks for approval.