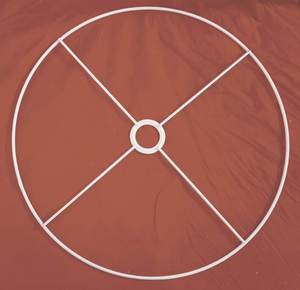

Lamp Shade Frame

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/27

1/27

0

0

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

About lamp shade frame

Where to Find Lamp Shade Frame Suppliers?

China remains the central hub for lamp shade frame manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated supply chains that specialize in metal stamping, wire forming, and surface treatment processes critical to lighting component fabrication. Guangdong’s Foshan and Zhongshan districts alone account for over 40% of China’s decorative lighting hardware output, supported by localized access to cold-rolled steel, aluminum alloys, and powder coating facilities.

The industrial ecosystems in these zones enable rapid prototyping and scalable production, with most suppliers operating within 30km of raw material processors and logistics hubs. This proximity reduces component lead times by 25–40% compared to offshore alternatives. Buyers benefit from flexible MOQs—ranging from 100 units for custom designs to under 50 for standard frames—as well as streamlined customization for dimensions, finishes (e.g., brushed nickel, antique brass), and mounting configurations. Average production cycles span 15–25 days, with air freight delivery to international markets within 7–10 days.

How to Choose Lamp Shade Frame Suppliers?

Adopt structured evaluation criteria to ensure supplier reliability and product consistency:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for process control. For markets requiring environmental compliance, verify RoHS or REACH declarations—particularly relevant for nickel-plated or chromed finishes. Request test reports on corrosion resistance (e.g., 48-hour salt spray testing per ASTM B117) and structural integrity under load (critical for pendant-mounted designs).

Production Capacity Assessment

Evaluate operational scale and technical capabilities through the following indicators:

- Minimum 2,000m² workshop area with dedicated zones for wire bending, welding, and finishing

- In-house tooling and mold-making capacity to support design iteration

- Automated CNC coiling and spot welding lines for consistent dimensional accuracy

Correlate facility size with order volume history; suppliers handling monthly outputs exceeding 50,000 units typically maintain higher process stability.

Procurement Risk Mitigation

Utilize third-party inspection services (e.g., SGS, TÜV) for pre-shipment quality audits, especially for initial orders. Require sample validation against provided CAD drawings or physical templates before mass production. Where applicable, structure payments via milestone disbursements tied to production stages, minimizing exposure to non-compliance or delays.

What Are the Best Lamp Shade Frame Suppliers?

No supplier data is currently available for detailed comparative analysis. However, industry benchmarks suggest prioritizing manufacturers with documented experience in export-grade lighting components, particularly those serving EU and North American markets where finish durability and material traceability are strictly regulated.

Performance Indicators to Monitor

In absence of specific supplier profiles, focus on measurable performance thresholds: target on-time delivery rates above 95%, average response time under 4 hours, and reorder rates exceeding 25% as proxies for customer satisfaction. Favor suppliers offering digital factory tours, real-time production updates, and accessible engineering teams for design validation. Prioritize partners with documented experience in UL/CE-compliant lighting assemblies when sourcing for regulated markets.

FAQs

How to verify lamp shade frame supplier reliability?

Validate certifications through accredited bodies and request audit trails covering material sourcing, work-in-process inspections, and final quality checks. Review customer references focusing on defect rates, packaging integrity, and responsiveness during post-production issues.

What is the typical sampling timeline?

Standard samples are produced within 7–12 days. Custom designs requiring new tooling may take 18–25 days. Air shipping adds 5–9 days depending on destination. Sample costs are typically applied toward first bulk orders.

Can suppliers accommodate custom finishes and sizes?

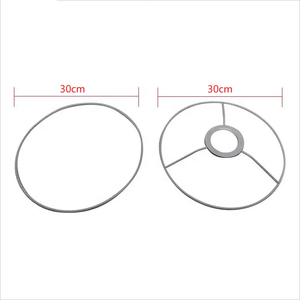

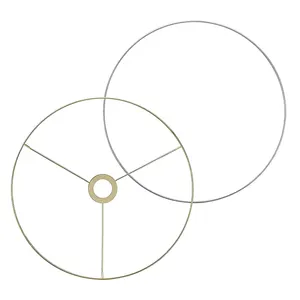

Yes, most established manufacturers support OEM specifications including diameter (150mm–600mm range), height (100mm–400mm), top/bottom ring configurations, and surface treatments such as electroplating, powder coating, or PVD finishes. Provide technical drawings or physical samples for accurate replication.

Do suppliers offer free samples?

Free samples are uncommon for custom frames. Standard design samples may be provided at cost or fully charged, with fees waived upon order confirmation. Expect sample pricing between $20–$60 per unit depending on complexity and finish.

What are common materials used in lamp shade frames?

Primary materials include low-carbon steel (SPCC), aluminum alloy (6061/6063), and stainless steel (SUS304). Steel dominates due to formability and cost efficiency, while aluminum is preferred for lightweight, corrosion-resistant applications. Material selection impacts plating adhesion, weight load limits, and compatibility with fabric or paper liners.