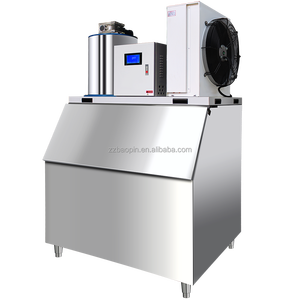

Large Ice Cube Maker Machine

About large ice cube maker machine

Where to Find Large Ice Cube Maker Machine Suppliers?

China remains the global epicenter for industrial ice-making equipment manufacturing, with key supplier clusters concentrated in Guangxi, Shandong, Jiangsu, and Shanghai. These regions host vertically integrated production ecosystems that combine refrigeration engineering expertise, metal fabrication capabilities, and export logistics infrastructure. Nanning and Shanghai are emerging as hubs for high-capacity commercial ice systems, while Shandong’s Jinan and Qingdao zones specialize in cost-competitive mass production of modular ice makers.

The geographic concentration enables streamlined supply chains—compressor units, evaporators, condensers, and control panels are sourced within 50km of final assembly plants. This localization reduces component lead times by 20–30% compared to decentralized models. Facilities typically operate automated production lines capable of assembling 100–500kg/day machines at cycle times under 4 hours per unit. Average delivery windows range from 25 to 40 days for standard configurations, with expedited builds possible for urgent orders backed by prepayment.

How to Choose Large Ice Cube Maker Machine Suppliers?

Procurement decisions should be guided by verified operational metrics and technical capacity:

Technical Compliance & Certification

Confirm adherence to international safety and performance standards such as CE, ISO 9001, and RoHS. For North American or EU markets, validate electrical compatibility (voltage: 110V/220V/380V) and refrigerant type (R404A, R410A, or eco-friendly alternatives). Request documentation on compressor brand (e.g., Bitzer, Copeland, Danfoss), cooling efficiency, and water consumption rates per kg of ice produced.

Production Capability Assessment

Evaluate suppliers based on verifiable infrastructure and output scale:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house design teams supporting OEM/ODM customization (e.g., logo integration, plug types, panel colors)

- Capacity to produce machines ranging from 100kg to 1,000kg+ daily output

- On-time delivery rate above 97% and response time under 5 hours

Cross-reference listed product ranges with actual order history and customer feedback to assess specialization depth in large cube versus flake or tube ice systems.

Transaction Security & Quality Assurance

Utilize secure payment frameworks that release funds post-inspection. Prioritize suppliers offering sample testing, third-party quality audits, or video factory verification. Inspect materials used in evaporator plates (typically stainless steel SUS304) and insulation layers (polyurethane foam density ≥38kg/m³). Demand performance data on ice clarity, hardness, melting resistance, and energy draw (kW·h/kg).

What Are the Best Large Ice Cube Maker Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Support | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Nanning Nanyuanfang Refrigeration Equipment Co., Ltd. | Guangxi, CN | US $760,000+ | 99% | ≤5h | 16% | 5 models (250–350kg/day) | Yes (shape, refrigerant, plug, logo, packaging) | 1 piece |

| Shandong Baixinhong Import And Export Co., Ltd. | Shandong, CN | US $470,000+ | 100% | ≤2h | 23% | 5 models (100–1,000kg/day) | Yes (color, door size, bucket, storage, logo) | 2 pieces |

| Shanghai Bingsu Refrigeration Technology Co., LTD. | Shanghai, CN | US $20,000+ | 100% | ≤1h | 16% | 5 models (90–1,000kg/day) | Limited (based on listed variants) | 1 set |

| Nantong Wuding Technology Co., Ltd. | Jiangsu, CN | US $60,000+ | 97% | ≤4h | <15% | 5 models (40–daily unspecified) | Branded series with luxury finish options | 1 set |

| Suzhou Iceman Refrigeration Equipment Co., Ltd. | Jiangsu, CN | US $40,000+ | 50% | ≤4h | 27% | 5 models (all 1-ton/day) | No explicit mention | 1 piece |

Performance Analysis

Nanning Nanyuanfang and Shandong Baixinhong demonstrate strong transactional reliability with high reorder rates and robust customization options, making them suitable for buyers requiring tailored branding or regional compliance adaptations. Shandong Baixinhong stands out for its sub-2-hour response time and balanced price-to-output ratio, particularly for mid-range 100–350kg machines. Shanghai Bingsu offers access to high-capacity 1-ton/day systems but lacks detailed customization transparency despite excellent responsiveness. Nantong Wuding focuses on premium finishes under a unified brand line, ideal for distributors seeking differentiated retail positioning. Suzhou Iceman presents a niche offering focused exclusively on 1-ton units at fixed pricing ($2,199–$2,299), though its 50% on-time delivery rate indicates potential fulfillment risks. Buyers prioritizing consistency should favor suppliers with >97% delivery performance and multi-model portfolios.

FAQs

What is the typical MOQ for large ice cube maker machines?

Most suppliers set MOQs between 1–2 units for standard models. Bulk pricing becomes available at 5+ units, with discounts varying by model complexity and customization level. Some manufacturers allow single-unit sampling for evaluation prior to volume orders.

How long does it take to receive an order?

Standard lead time ranges from 25 to 40 days after deposit confirmation. Express production may reduce this to 15–20 days for uncustomized units, depending on factory workload and component availability.

Can I customize the machine for my market?

Yes, leading suppliers support OEM/ODM services including voltage adjustment, plug type (NEMA, Schuko, etc.), color scheme, logo printing, user interface language, and packaging design. Confirmation of these options should be obtained before order placement.

Are samples available for testing?

Sample availability varies. Some suppliers offer functional units for testing at full price, with credit applied upon subsequent bulk order. Others require separate sampling fees covering material and labor costs.

What refrigerants are commonly used in these machines?

R404A and R410A are most prevalent due to their thermodynamic efficiency in medium-temperature applications. However, environmentally conscious buyers can request low-GWP alternatives such as R290 (propane) or R134a, subject to manufacturer compatibility.