Laser Key Maker

About laser key maker

Where to Find Laser Key Maker Suppliers?

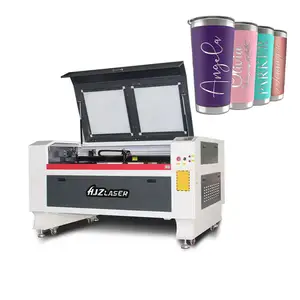

China remains the central hub for laser key maker production, with key manufacturing clusters in Guangdong and Hubei provinces driving innovation and scale. Shenzhen-based suppliers specialize in promotional and personalized laser-engravable keychains, leveraging localized access to synthetic leather, metal blanks, and acrylic materials. These regions benefit from integrated supply chains that reduce material procurement lead times by 20–30% compared to offshore alternatives.

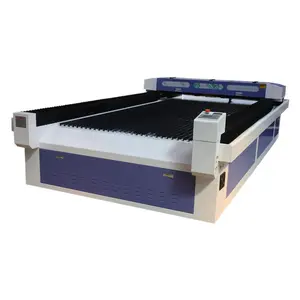

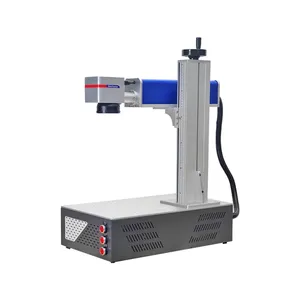

Hubei and Shandong emerge as centers for industrial laser equipment manufacturing, hosting firms that produce MOPA fiber and CO₂ laser marking systems capable of high-precision engraving on metals, plastics, and composites. These clusters feature vertically aligned component sourcing—laser sources, galvanometers, software stacks—enabling rapid assembly and calibration. Buyers gain access to ecosystems where engineering support, spare parts logistics, and technical training are available within 50km radii, reducing deployment timelines.

The proximity of raw material suppliers and CNC fabrication workshops allows for MOQ flexibility, ranging from 10 units for sample testing to 500+ for bulk promotional orders. Lead times average 7–15 days for finished keychains and 15–30 days for laser machines, depending on configuration complexity and customization scope.

How to Choose Laser Key Maker Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical Capability & Compliance

Verify that suppliers possess relevant quality management certifications such as ISO 9001, particularly for laser machinery manufacturers. For export to regulated markets (EU, North America), confirm CE or RoHS compliance documentation for electrical and optical components. Request proof of laser safety standards adherence (e.g., IEC 60825) and software compatibility (support for CorelDRAW, AutoCAD, LightBurn).

Production Infrastructure Assessment

Evaluate operational capacity through verifiable metrics:

- Minimum factory area of 1,000m² for equipment producers; 500m² for accessory/blank manufacturers

- In-house laser processing capabilities (fiber, CO₂, UV) with adjustable power (30W–150W)

- Customization support for material type, size, logo engraving, and packaging design

Cross-reference online revenue data and reorder rates (>25% indicates customer retention) to assess reliability and service consistency.

Procurement Risk Mitigation

Utilize transaction safeguards such as third-party inspection services or secure payment platforms. Prioritize suppliers with documented on-time delivery performance (target ≥95%) and sub-4-hour response times for technical queries. Conduct video audits to verify claimed production lines and inventory levels before large-scale ordering.

What Are the Best Laser Key Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Risun Trading Co., Ltd. | Guangdong, CN | Metal & leather keychains, promotional items | US $100,000+ | 100% | ≤4h | 25% | 50–100 pcs | $0.79–$1.28 |

| Hubei Toch Technology Co., Ltd. | Hubei, CN | Fiber & CO₂ laser marking machines | US $320,000+ | 95% | ≤2h | <15% | 1 set | $1,014–$3,500 |

| Shenzhen Mastergift Co., Ltd. | Guangdong, CN | Laserable leatherette, metal plates, gift sets | US $3,000+ | 80% | ≤4h | <15% | 50–500 pcs | $0.24–$1.97 |

| Jinan Scnc Machinery Co., Ltd. | Shandong, CN | Desktop laser engravers, cutting systems | US $120,000+ | 100% | ≤1h | 37% | 1 set | $800–$6,500 |

| Guangzhou Norpie Trading Co., Ltd. | Guangdong, CN | Leather, metal, and novelty engraved keychains | US $240,000+ | 100% | ≤8h | 20% | 10–100 pcs | $0.37–$0.62 |

Performance Analysis

Shenzhen Risun and Guangzhou Norpie offer competitive pricing and low MOQs ideal for promotional campaigns and small business branding, backed by 100% on-time delivery records. Hubei Toch and Jinan Scnc represent core industrial suppliers, providing advanced laser systems with customizable power, software, and axis configurations. Jinan Scnc stands out with a 37% reorder rate and one-hour average response time, indicating strong post-sale support and operational agility.

Suppliers in Guangdong dominate in consumer-ready products, offering extensive customization in shape, color, and engraving depth. Meanwhile, Shandong and Hubei focus on capital equipment, enabling end-users to integrate laser marking in-house. Buyers seeking turnkey solutions should prioritize suppliers with multilingual software interfaces, two-year warranties, and remote diagnostics support.

FAQs

How to verify laser key maker supplier reliability?

Cross-check declared certifications with official databases. Request detailed product specifications, including laser wavelength, marking speed, cooling method, and supported file formats. Analyze transaction history for consistent fulfillment performance and evaluate customer feedback focused on technical support responsiveness and machine stability.

What is the typical MOQ and sampling timeline?

For pre-made keychain blanks, MOQs range from 10 to 500 pieces, with samples deliverable in 5–7 days. Custom laser machines require minimum order of one set, with production lead times of 15–25 days. Sample costs for engraved units typically range from $10–$50, often creditable toward bulk orders.

Can suppliers provide custom laser engraving software?

Yes, most industrial suppliers offer OEM/ODM software integration, supporting barcode, QR code, serial number automation, and variable data printing. Confirm compatibility with Windows, macOS, or standalone DSP controllers prior to purchase.

Do manufacturers support dropshipping or private labeling?

Many suppliers, especially in Guangdong, offer neutral packaging and logo branding services. Some provide dropshipping with direct-to-customer fulfillment, though this must be confirmed per supplier policy and volume agreement.

How to assess laser machine durability and maintenance needs?

Demand MTBF (Mean Time Between Failures) reports and laser source lifespan data (typically 100,000 hours for fiber lasers). Verify availability of local service technicians or remote troubleshooting support. Regular maintenance includes lens cleaning, alignment checks, and software updates every 3–6 months under standard usage.