Layers Under Artificial Grass

About layers under artificial grass

Where to Find Suppliers for Layers Under Artificial Grass?

China remains the central hub for manufacturing layers under artificial grass, with key production clusters in Guangdong, Shandong, and Hebei provinces. These regions host vertically integrated facilities specializing in synthetic turf underlayments such as foam shock pads, rubber infills, and XPE/EPE cushioning layers. Guangzhou and Shenzhen-based suppliers leverage proximity to polymer processing centers and export ports, enabling efficient material sourcing and containerized shipping. Hebei and Shandong manufacturers benefit from concentrated landscaping material ecosystems, where raw extrusion, lamination, and roll-cutting operations are co-located within 50km supply corridors.

The industrial clusters support scalable production through automated foaming lines and continuous lamination systems, allowing monthly outputs exceeding 100,000 square meters per facility. Buyers gain access to mature technical networks that integrate material testing labs, packaging automation, and multimodal logistics—reducing lead times to 20–35 days for bulk orders. Cost advantages range from 20–40% compared to European or North American producers due to lower labor inputs and localized thermoplastic feedstock supply chains. Customization capabilities—including thickness (6–20mm), density grading, and anti-UV stabilization—are standard across mid-tier and premium suppliers.

How to Choose Suppliers for Layers Under Artificial Grass?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Material & Performance Specifications

Confirm base materials used—common options include cross-linked polyethylene (XPE), expanded polyethylene (EPE), recycled rubber, or composite foam blends. Demand test reports verifying compression recovery (ASTM F1701), shock absorption (≥45% reduction in G-max), and durability under UV exposure (minimum 1,500 hours QUV). For sports applications, compliance with FIFA Quality Pro or World Rugby Regulation 22 standards is essential.

Production Capacity Verification

Assess infrastructure indicators:

- Minimum factory area of 3,000m² for consistent volume output

- In-house foam extrusion or rubber calendering lines (not third-party sourced)

- Dedicated quality control stations with digital thickness and density gauges

Cross-reference declared capacity with on-time delivery rates; prioritize suppliers maintaining ≥98% fulfillment punctuality.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as trade assurance or escrow services until product inspection at destination. Evaluate reorder rates as a proxy for customer satisfaction—rates above 20% indicate reliable performance. Request physical or digital samples before full procurement to validate texture, resilience, and dimensional accuracy. MOQs typically range from 50 to 1,000 square meters, with unit prices between $0.70 and $7.00 depending on composition and thickness.

What Are the Leading Layers Under Artificial Grass Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Customization Options | Main Product Focus | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Green Tower Sports Facilities Co., Ltd. | Guangdong, CN | US $120,000+ | 98% | 17% | ≤3h | Color, size, logo, packaging | Artificial grass with integrated foam underlay | 100 sqm |

| Shenzhen Flyon Sports Co., Ltd. | Guangdong, CN | US $80,000+ | 87% | <15% | ≤3h | Color, size, logo, packaging | Shock pads, hybrid grass systems | 500 sqm |

| Shandong Meisen Artificial Lawn Co., Ltd. | Shandong, CN | US $6,000+ | 100% | <15% | ≤4h | Limited customization | Rubber and foam underlayments (3,430 listings) | 150 sqm |

| Yangzhou Lvbao Artificial Turf Co., Ltd. | Jiangsu, CN | US $100,000+ | 100% | 20% | ≤9h | Size, color, thickness | Broad landscaping portfolio including underlayers | 50 sqm |

| Hebei Heihe Commerce Co., Ltd. | Hebei, CN | US $310,000+ | 100% | <15% | ≤1h | Color, material, size, logo | Thin decorative and functional underlays (10mm) | 50 sqm |

Performance Analysis

Hebei Heihe leads in responsiveness and revenue volume, offering sub-hour inquiry resolution and highly flexible MOQs starting at 50 square meters. Despite lower reorder rates, its extensive customization capability and competitive pricing ($0.70–1.20/sqm) make it suitable for niche or trial orders. Yangzhou Lvbao stands out with a 20% reorder rate—the highest in the dataset—indicating strong buyer retention, supported by low MOQ thresholds and diverse product integration. Shandong Meisen specializes in high-volume rubber underlayments but has limited after-sales engagement. Guangzhou Green Tower and Shenzhen Flyon focus on performance-grade shock pads for sports fields, though Flyon’s 87% on-time delivery suggests potential logistical constraints. Suppliers with 100% on-time records should be prioritized for time-sensitive installations.

FAQs

What materials are commonly used in underlayers for artificial grass?

Polyethylene foams (XPE, EPE), recycled crumb rubber, and composite elastomeric pads are most prevalent. XPE offers superior moisture resistance and structural memory, while rubber provides higher impact absorption. Material selection depends on application—residential lawns favor lightweight foams, whereas sports surfaces require high-density rubber or dual-layer systems.

What is the typical lead time for bulk orders?

Standard production cycles range from 20 to 35 days after order confirmation, excluding shipping. Expedited production (12–18 days) may be available for urgent contracts, subject to MOQ adjustments and surcharges. Sea freight adds 25–40 days for transoceanic deliveries.

Can suppliers provide certification for their underlay products?

While ISO 9001 certification is not universally declared, leading suppliers conduct internal batch testing for compression set, water absorption, and tensile strength. Third-party lab verification (e.g., SGS, TÜV) can often be arranged upon request, particularly for commercial or municipal projects requiring compliance documentation.

Do suppliers offer free samples?

Sample policies vary: many provide small-format samples (30x30cm) at no cost, but buyers typically cover express shipping. For full-thickness or customized samples, expect charges covering 30–50% of production cost, refundable against subsequent orders.

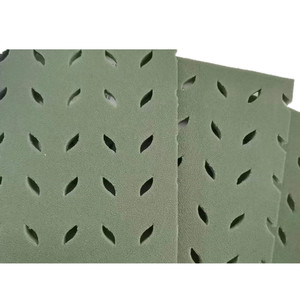

How to assess underlayer compatibility with artificial turf?

Verify dimensional stability—underlays must resist creep under load and maintain flatness after installation. Conduct field adhesion tests with chosen turf backing to prevent delamination. Ensure drainage perforations (if present) align with sub-base design. Technical datasheets should specify coefficient of friction, thermal expansion rate, and pH neutrality to avoid turf degradation.