Laying Artificial Grass On Slabs

1/19

1/19

1/8

1/8

1/21

1/21

1/3

1/3

1/13

1/13

1/9

1/9

1/7

1/7

1/9

1/9

1/16

1/16

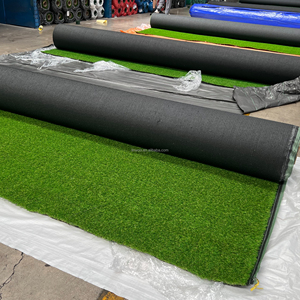

About laying artificial grass on slabs

Where to Find Suppliers for Laying Artificial Grass on Slabs?

China remains the dominant hub for artificial grass manufacturing, with key production clusters in Zhejiang, Shandong, and Shanghai offering specialized capabilities for outdoor surfacing solutions. These regions host vertically integrated facilities that manage extrusion, tufting, backing lamination, and finishing processes in-house, enabling tight control over material consistency and cost efficiency. Zhejiang and Shandong provinces collectively account for over 70% of China’s synthetic turf exports, supported by mature supply chains for polyethylene (PE) and polypropylene (PP) raw materials.

Suppliers in these zones specialize in products optimized for hard substrate installation, including perforated backings for drainage and low-profile pile heights (7–35mm) suitable for slab applications. The proximity of logistics hubs like Ningbo and Qingdao ports reduces shipping lead times by 10–15 days compared to inland manufacturers. Buyers benefit from scalable production capacity, with leading factories reporting monthly outputs exceeding 500,000 square meters and average unit costs ranging from $0.57 to $5.99 per square meter, depending on fiber density and UV stabilization.

How to Choose Suppliers for Artificial Grass Installation on Slabs?

Effective supplier evaluation should focus on technical suitability, operational reliability, and transactional safeguards:

Material & Design Specifications

Confirm that products are engineered for rigid substrates, featuring anti-slip latex backing, high drainage perforation rates (>15 holes/in²), and dimensional stability under thermal expansion. Pile heights between 15–30mm are optimal for slab installations to minimize wind uplift while maintaining aesthetic depth. Request product cut sheets detailing denier count, stitch rate (stitches/m), and DTEX values to assess durability.

Quality Assurance Protocols

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not universally listed, verify compliance through third-party testing reports for UV resistance (ASTM G154), colorfastness (AATCC 16), and tensile strength (ISO 5081). Independent lab verification ensures performance longevity exceeding 8–10 years in direct sunlight exposure.

Production & Fulfillment Metrics

Assess scalability using verified operational data:

- Minimum facility area of 2,000m² for consistent batch output

- In-house tufting and coating lines to reduce outsourcing dependencies

- On-time delivery rate >90% as an indicator of logistical reliability

Cross-reference response times (target ≤2 hours) and reorder rates to gauge customer satisfaction and service responsiveness.

What Are the Leading Suppliers for Laying Artificial Grass on Slabs?

| Company Name | Main Products | Online Revenue | Min. Order Quantity | Avg. Price Range ($/sqm) | On-Time Delivery | Response Time | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Zhejiang Shendu Import And Export Co., Ltd. | Artificial Grass, Golf Mats, Tennis Court Equipment | US $270,000+ | 500 sqm | $0.88–4.90 | 66% | ≤2h | 20% |

| Shanghai Kaicheng Landscape Engineering Co., Ltd. | Artificial Grass, Fencing, Garden Ornaments | US $2,000+ | 20–50 sqm | $0.57–5.66 | 100% | ≤6h | <15% |

| Shandong Asia Europe Evergreen International Trade Co., Ltd. | Artificial Grass, Garden Netting, Shade Sails | US $60,000+ | 10–100 sqm | $1.80–3.36 | 91% | ≤1h | <15% |

| Weihai Deyuan Network Industry Co., Ltd. | Artificial Turf Tiles, Splicing Boards, Custom Mats | US $410,000+ | 1 pc – 100 sqm | $0.38–4.99 | 100% | ≤1h | <15% |

| Guangzhou LYT Toys Co., Ltd. | Artificial Grass, Inflatable Structures, Trade Show Tents | US $120,000+ | 10–50 sqm | $1.00–2.45 | 100% | ≤3h | 40% |

Performance Analysis

Weihai Deyuan and Guangzhou LYT stand out for customization flexibility and rapid engagement, both offering sub-1-hour response times and accepting orders as small as one piece or square meter—ideal for prototyping or niche applications. Shanghai Kaicheng and Weihai Deyuan achieve perfect on-time delivery records, indicating robust production scheduling despite lower reorder rates. Guangzhou LYT’s 40% reorder rate suggests strong end-user satisfaction, likely driven by competitive pricing and diversified product integration. Zhejiang Shendu offers the lowest entry price point at $0.88/sqm but reports a below-average 66% on-time delivery rate, signaling potential fulfillment risks for time-sensitive projects.

FAQs

What MOQs are typical for artificial grass on slabs?

Minimum order quantities vary significantly: bulk orders start at 500 sqm for standard rolls, while sample or trial batches can be as low as 10–20 sqm. Modular tile formats may have MOQs measured in units (e.g., 1 piece). Suppliers with flexible MOQs accommodate R&D testing and small-scale residential retrofits.

Are customization options available?

Yes, select manufacturers offer tailored solutions including custom colors, logo embedding, variable pile heights, and specialized backing for adhesive bonding to concrete slabs. Weihai Deyuan explicitly lists color, size, logo, and packaging modifications, making it a strategic partner for branded or architectural integrations.

What is the average lead time for production and shipping?

Standard production lead time ranges from 15–25 days after order confirmation. Air freight delivers samples within 7–10 days globally; sea freight for full container loads (FCL) takes 25–35 days depending on destination port. Expedited production (10–14 days) is available from suppliers with excess capacity.

Do suppliers provide installation guidance for slab surfaces?

While formal manuals are not always included, most suppliers recommend surface cleaning, use of polyurethane adhesives, perimeter edging, and expansion gaps for thermal movement. Technical support is typically accessible via messaging platforms during business hours, with some offering video consultations.

How to verify product suitability before procurement?

Request physical or digital samples to evaluate texture, backing integrity, and color accuracy under natural light. Conduct peel tests on adhesive bonds and simulate foot traffic to assess fiber resilience. Verify compliance documentation for REACH, RoHS, or California Proposition 65 if supplying to regulated markets.