Led Matrix Display Supplier

Top sponsor listing

Top sponsor listing

About led matrix display supplier

Where to Find LED Matrix Display Suppliers?

China remains the global epicenter for LED matrix display manufacturing, with Shenzhen in Guangdong Province serving as the primary hub due to its advanced optoelectronic supply chain and R&D infrastructure. Secondary production clusters in Henan and Zhongshan offer competitive alternatives, particularly for cost-sensitive buyers seeking standardized indoor or outdoor panels. These regions benefit from vertically integrated ecosystems encompassing PCB fabrication, driver IC assembly, and aluminum frame extrusion, enabling rapid prototyping and scalable batch production.

The industrial concentration supports efficient component sourcing—LED chips, power supplies, control systems, and structural frames are available within 50km of major factories—reducing lead times by up to 25% compared to non-specialized regions. Buyers gain access to suppliers capable of fulfilling orders ranging from single modules to full wall installations, with typical production cycles of 15–30 days depending on customization level. Key advantages include high responsiveness (average response time ≤2 hours), proven on-time delivery rates exceeding 93%, and robust export logistics networks supporting global distribution.

How to Choose LED Matrix Display Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Product Range

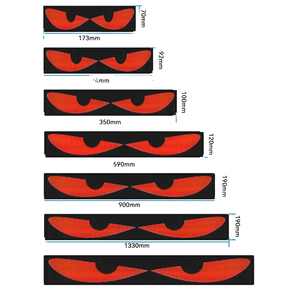

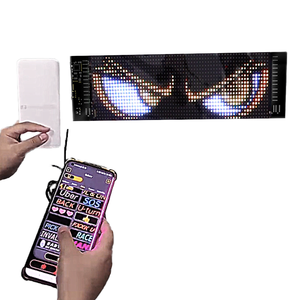

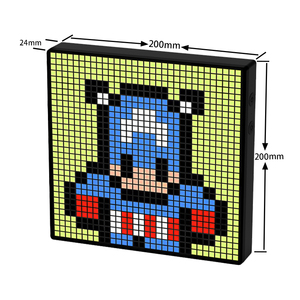

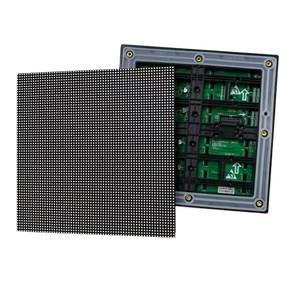

Assess whether suppliers offer required specifications: pixel pitch (P1–P10 common), resolution (e.g., 32x32, 64x32, 320x160), brightness (≥5,000 nits for outdoor), viewing angle (≥120°), and control system compatibility (synchronous/asynchronous, USB/SD card, Wi-Fi). Verify availability of customization options including module configuration, color palette (RGB, RGBW), waterproofing (IP65 standard for outdoor), and mounting methods (wall, truss, hydraulic lift).

Production Capacity and Quality Metrics

Prioritize manufacturers demonstrating measurable performance indicators:

- On-time delivery rate ≥95%

- Response time ≤2 hours

- Reorder rate below 20% indicating customer satisfaction

- Online revenue exceeding US $200,000 annually as proxy for volume capability

Cross-reference product listings with evidence of in-house engineering support, spare panel availability, and documentation such as wiring diagrams, control software, and structural drawings.

Transaction Security and After-Sales Support

Favor suppliers offering comprehensive after-sales services, including technical guidance, firmware updates, and replacement modules. Confirm packaging standards (flight cases, wooden crates) and compliance with international shipping requirements. Where applicable, request sample testing to validate luminance consistency, color calibration, and thermal stability under load conditions.

What Are the Best LED Matrix Display Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Annual Online Revenue | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Yake LED Tech Co., Limited | Custom Manufacturer | Digital Signage, LED Displays | 98% | <15% | ≤2h | US $2.3M+ | Yes (module, structure, control system, power supply) | 1 set |

| Henan Guanchi Industrial Co., Ltd. | Manufacturer | LED Display, Hologram Equipment, Solar Lights | 100% | <15% | ≤2h | US $6,000+ | Limited (predefined models) | 2 pieces |

| ZhongShan Bluestar Photoelectric Co., Ltd. | Manufacturer | LED Display, Electronic Signs, Photographic Lighting | 93% | 19% | ≤2h | US $50,000+ | Moderate (brightness, size, message programming) | 1 piece |

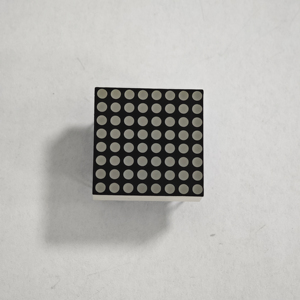

| Dongguan Jinyu Optoelectronic Technology Co., Ltd. | Manufacturer | LED Dot Matrix, Segment Displays, Diodes | 100% | 33% | ≤1h | US $10,000+ | High (custom sizes, colors, pin configurations) | 100–1000 pieces |

| Shenzhen Yhf Optoelectronic Technology Co., Ltd. | Multispecialty Supplier | Indoor/Outdoor LED Modules, P1–P10 Panels | 84% | 21% | ≤2h | US $200,000+ | Yes (color, logo, packaging, graphic design) | 1 piece |

Performance Analysis

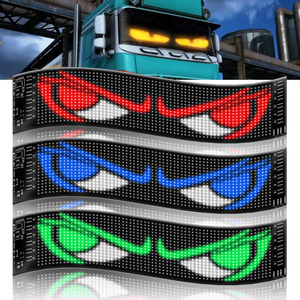

Shenzhen-based Shenzhen Yake LED Tech leads in scalability and customization depth, backed by significant annual revenue and comprehensive technical offerings. Henan Guanchi stands out for perfect on-time delivery despite lower sales volume, suggesting strong process discipline. Dongguan Jinyu excels in responsiveness (≤1h) and low-cost dot matrix solutions but exhibits a high reorder rate (33%), potentially indicating initial quality inconsistencies. ZhongShan Bluestar offers balanced capabilities for mid-tier applications, while Shenzhen Yhf provides flexible customization at moderate scale. Buyers prioritizing reliability should favor suppliers with on-time delivery >95% and reorder rates <20%. For niche applications like truck-mounted or rotating screens, verify prior project experience and structural design validation.

FAQs

What certifications should LED matrix display suppliers have?

While not universally mandated, reputable suppliers comply with CE, RoHS, and FCC standards for electromagnetic compatibility and hazardous substance restrictions. For commercial installations in regulated markets, UL or ETL listing may be required. Request test reports for ingress protection (IP65/IP68) and thermal performance under continuous operation.

What is the typical lead time for LED matrix displays?

Standard products ship within 7–15 days after order confirmation. Custom configurations involving unique pixel layouts, control systems, or structural modifications require 20–30 days. Rush production may reduce timelines by 30% with expedited fees.

Do suppliers offer free samples?

Most suppliers provide paid samples to cover material and handling costs. Sample prices typically range from $6–$50 depending on complexity. Full reimbursement may apply upon placement of qualifying bulk orders (e.g., ≥50 units).

Can LED matrix displays be customized for outdoor use?

Yes. Outdoor-rated units feature sealed enclosures (IP65+), high-brightness LEDs (≥8,000 nits), anti-UV materials, and wide operating temperature ranges (–20°C to +60°C). Confirm inclusion of surge protectors, waterproof connectors, and corrosion-resistant frames for long-term durability.

What control systems are commonly used?

Asynchronous systems using SD/USB for static content are standard for small displays. Synchronous controllers with HUB75 interfaces support real-time video playback and larger installations. Advanced setups integrate mobile apps, Wi-Fi, or DMX for dynamic content management and synchronization across multiple panels.