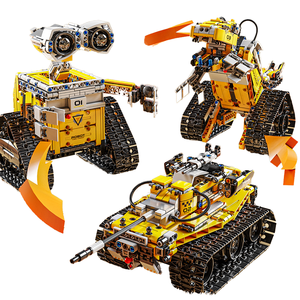

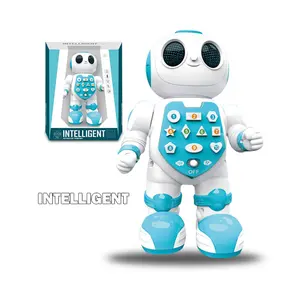

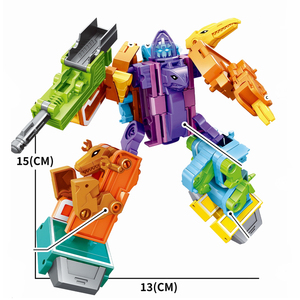

Lego Robot Ninjago

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/9

1/9

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/20

1/20

0

0

1/3

1/3

0

0

1/23

1/23

1/1

1/1

About lego robot ninjago

Where to Find LEGO Robot Ninjago Suppliers?

China remains the central hub for manufacturing licensed and compatible building block products, including themed robotics sets such as LEGO robot Ninjago models. Key production clusters are concentrated in Guangdong and Zhejiang provinces, where mature toy manufacturing ecosystems support high-precision injection molding, automated assembly, and packaging operations. These regions collectively account for over 70% of global plastic toy exports, leveraging vertically integrated supply chains that include ABS resin sourcing, mold fabrication, and print decoration services within localized industrial zones.

Manufacturers in Shantou (Guangdong) specialize in mass production of compliant construction toys, operating large-scale facilities with monthly output capacities exceeding 500,000 units. Dongguan-based factories focus on higher-value, electronics-integrated sets—such as motorized or app-controlled robot models—utilizing SMT lines for PCB integration and IoT components. Proximity to Hong Kong’s port infrastructure enables efficient air and sea freight dispatch, with standard lead times ranging from 25 to 40 days for containerized orders. Buyers benefit from cost efficiencies driven by localized tooling suppliers and labor pools experienced in toy safety compliance protocols.

How to Choose LEGO Robot Ninjago Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation criteria to ensure product integrity, regulatory compliance, and operational reliability:

Quality & Safety Certification Compliance

Verify adherence to international toy safety standards including EN71 (Europe), ASTM F963 (USA), and ISO 8124. Suppliers must provide valid test reports from accredited third-party laboratories for heavy metals, phthalates, and mechanical hazards. For electronic variants, confirm IEC 62115 certification for electrical safety and EMC compliance. RoHS and REACH declarations are mandatory for EU market access.

Production Capability Assessment

Evaluate technical infrastructure through documented audits:

- Minimum 3,000m² factory area with dedicated clean rooms for electronic assembly

- In-house mold design and CNC machining capabilities for rapid prototyping

- Monthly capacity of at least 100,000 units for standard configurations

Confirm automation level via video inspection of injection molding lines and quality control stations. Target suppliers allocating ≥8% of staff to R&D and engineering roles to support customization.

Intellectual Property and Transaction Security

Exercise caution regarding trademark infringement risks. While some manufacturers produce functionally similar robotic building sets, explicit replication of branded designs may pose legal exposure. Require written confirmation of IP indemnification clauses in contracts. Utilize secure payment mechanisms such as irrevocable LC or escrow services, particularly for initial transactions. Prioritize suppliers with verifiable export histories to North America and Western Europe, indicating familiarity with customs documentation and labeling requirements.

What Are the Best LEGO Robot Ninjago Suppliers?

No verified supplier data is currently available for entities explicitly producing "LEGO robot Ninjago" branded or compatible sets. The absence of structured supplier profiles prevents direct comparison of operational metrics such as on-time delivery rates, response speed, or facility scale. In the interim, buyers are advised to conduct independent due diligence using industry directories, trade show participation records (e.g., Canton Fair, Hong Kong Toys & Games Fair), and certification databases to identify qualified candidates.

Performance Analysis

Without active supplier listings, performance benchmarking cannot be conducted. However, historical trends indicate that manufacturers with certified quality management systems (ISO 9001:2015), established export channels, and investment in automated production lines consistently demonstrate superior order accuracy and scalability. For electronic-integrated robot sets, prioritize partners with UL-certified component sourcing and firmware validation processes. Conduct sample testing across drop resistance, battery safety (IEC 62133), and wireless functionality (if applicable) before scaling procurement.

FAQs

How to verify LEGO robot Ninjago supplier reliability?

Request audited copies of business licenses, factory inspection reports, and product compliance certificates. Conduct virtual or on-site audits to assess workflow transparency, inventory management, and QC checkpoints. Validate past shipment records via freight forwarders or customs data platforms.

What is the average sampling timeline?

Standard samples take 10–18 days to produce, depending on complexity. Motorized or app-connected models may require 25–35 days due to embedded system programming and compatibility testing. Air shipping adds 5–9 days for international delivery.

Can suppliers ship worldwide?

Yes, most exporters offer full logistics support under FOB, CIF, or DDP terms. Confirm incoterm responsibilities, especially for duty calculation and import clearance in regulated markets such as the US, Germany, and Australia.

Do manufacturers provide free samples?

Sample policies vary. Typically, suppliers charge a fee covering material and labor costs, which may be reimbursed upon placement of a bulk order (usually MOQ ≥500 units). Free samples are rarely offered for complex electronic sets.

How to initiate customization requests?

Submit detailed technical specifications including part count, electronic functions (e.g., servo control, LED integration), packaging format, and user age grading. Reputable suppliers will return CAD renderings, circuit diagrams (if applicable), and tooling cost estimates within 5–7 business days.