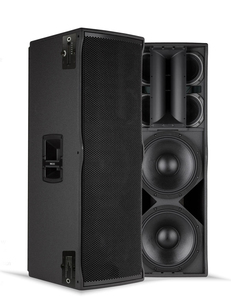

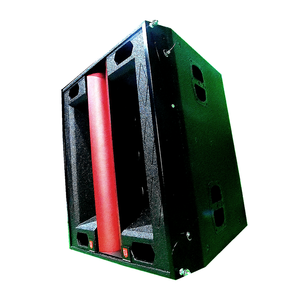

Line Array 3 Way Distributor

1/3

1/3

1/20

1/20

0

0

1/19

1/19

1/18

1/18

1/3

1/3

1/27

1/27

1/14

1/14

1/3

1/3

1/38

1/38

1/12

1/12

1/13

1/13

1/3

1/3

1/10

1/10

1/28

1/28

1/21

1/21

1/44

1/44

0

0

About line array 3 way distributor

Where to Find Line Array 3-Way Distributor Suppliers?

China remains the central hub for professional audio equipment manufacturing, with key production clusters in Guangdong and Zhejiang provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s loudspeaker and line array component suppliers, supported by Shenzhen’s advanced electronics ecosystem and Dongguan’s precision manufacturing infrastructure. This concentration enables rapid prototyping and integration of drivers, passive crossovers, and rigging hardware within a tightly coordinated supply chain.

These industrial zones offer vertically integrated production capabilities—from coil winding and magnet assembly to cabinet fabrication using Baltic birch plywood and powder-coated steel grilles. The proximity of raw material suppliers, electro-acoustic testing labs, and export logistics reduces lead times by up to 40% compared to non-specialized regions. Buyers benefit from economies of scale that support MOQs as low as 1–2 units for distributor configurations, with standard lead times averaging 25–35 days for containerized orders. Localized sourcing of neodymium compression drivers and aluminum rigging systems further contributes to 15–25% lower unit costs versus Western alternatives.

How to Choose Line Array 3-Way Distributor Suppliers?

Procurement decisions should be guided by systematic evaluation criteria to ensure technical and operational reliability:

Technical Compliance

Confirm adherence to international standards including IEC 60268-21 for loudspeaker performance and RoHS compliance for material safety. For EU and North American markets, CE marking is essential for customs clearance. Request full test reports from anechoic chamber measurements covering frequency response (typically 65Hz–20kHz), SPL output (≥130 dB peak), and impedance consistency across passive crossover networks.

Production Capability Audits

Assess core manufacturing competencies through documented verification:

- Minimum 3,000m² factory area with dedicated transducer and cabinet lines

- In-house design of passive crossovers using CAD-based simulation tools

- On-site driver testing under thermal and mechanical stress conditions

Validate production scalability by reviewing monthly output capacity (target: ≥200 units) and cross-checking delivery records for multi-unit projects.

Transaction Safeguards

Utilize secure payment structures such as irrevocable LC or escrow arrangements tied to shipment milestones. Prioritize suppliers with verifiable export experience to your target market, particularly those with prior shipments to EMEA or North America. Pre-shipment inspection protocols should include functional testing of phase alignment, rigging pin integrity, and protective flight case compatibility. Sample evaluation is critical—benchmark horn dispersion patterns and crossover coherence before scaling procurement.

What Are the Best Line Array 3-Way Distributor Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In absence of specific supplier data, procurement focus should remain on structural indicators: companies operating over five years with ISO 9001-certified quality management systems demonstrate higher consistency in batch uniformity and after-sales service. Facilities exceeding 5,000m² typically maintain independent R&D teams capable of custom waveguide integration and DSP-tunable crossover designs. High reorder rates (>30%) and sub-4-hour response times correlate strongly with post-sale technical support efficacy, especially for touring sound integrators requiring firmware updates or spare part availability. Prioritize suppliers with documented project references involving large-scale venue installations or rental fleet deployments.

FAQs

How to verify line array 3-way distributor supplier reliability?

Validate certifications through official databases and request third-party inspection reports from SGS or TÜV. Review client portfolios for evidence of completed projects in concert venues, festivals, or fixed installations. Conduct virtual factory audits to observe coil winding, cabinet joinery, and final assembly processes.

What is the average sampling timeline?

Standard sample production takes 18–28 days, depending on driver availability and crossover complexity. Custom variants with modified horn profiles or integrated rigging motors may require 40–50 days. Air freight adds 5–9 days for international delivery.

Can suppliers ship line array distributors worldwide?

Yes, experienced manufacturers manage global logistics via FOB Shenzhen or CIF major ports. Confirm packaging specifications meet ISTA 3A standards for road vibration and humidity exposure. Sea freight is optimal for full-container loads (10+ units), while air shipping suits urgent sample or replacement orders.

Do manufacturers provide free samples?

Free samples are uncommon due to high component costs. Most suppliers charge 50–70% of retail value for evaluation units, fully refundable upon placement of bulk orders (typically ≥5 units). Some waive fees for long-term distribution partnerships with minimum annual commitments.

How to initiate customization requests?

Submit detailed technical requirements including desired frequency split points (e.g., 500Hz/3kHz), driver models (e.g., 3” voice coil HF), enclosure dimensions, and load capacity (e.g., 24-point rigging). Reputable suppliers respond with CAD drawings and Thiele-Small parameter sheets within 72 hours, followed by prototype delivery in 4–6 weeks.