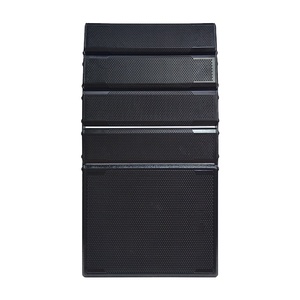

Line Array Box For Assembly Supplier

1/12

1/12

CN

CN

1/10

1/10

1/27

1/27

1/3

1/3

1/3

1/3

0

0

1/21

1/21

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/1

1/1

1/31

1/31

0

0

1/3

1/3

1/3

1/3

About line array box for assembly supplier

Where to Find Line Array Box for Assembly Suppliers?

China remains the central hub for audio equipment manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving efficiency in line array box fabrication. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s professional audio system suppliers, supported by Shenzhen’s advanced electronics ecosystem and Dongguan’s metalworking infrastructure. This concentration enables seamless integration of acoustic engineering, cabinet construction, and hardware assembly under one supply chain.

Zhejiang’s Ningbo and Hangzhou zones specialize in precision woodworking and composite material processing, offering cost advantages for enclosures requiring Baltic birch plywood or molded fiberglass. These industrial networks operate with vertically integrated workflows—combining CNC routing, powder coating, and rigging hardware installation—reducing component lead times by 25–40% compared to fragmented supplier models. Buyers benefit from localized sourcing ecosystems where raw materials, electrical components, and logistics providers are accessible within 30km radii, supporting faster prototyping and scalable order fulfillment.

How to Choose Line Array Box for Assembly Suppliers?

Implement rigorous evaluation criteria when selecting manufacturing partners:

Technical Compliance

Confirm adherence to ISO 9001 standards as a baseline for quality management. For exports to Europe or North America, verify CE marking and RoHS compliance to ensure electromagnetic compatibility and restricted substance control. Request test reports on structural integrity, including finite element analysis (FEA) simulations for rigging point load capacity (typically rated 8:1 safety factor).

Production Capability Audits

Assess operational scale and technical depth through these benchmarks:

- Minimum 3,000m² factory area with dedicated assembly lines

- In-house CNC machining (≥4-axis) and wood lamination capabilities

- Engineering team comprising ≥15% of total staff for design validation

Validate claims via facility walkthrough videos and production capacity data, targeting suppliers with documented monthly output exceeding 500 units for consistent availability.

Transaction Safeguards

Utilize secure payment structures such as third-party escrow until product inspection at destination. Review supplier performance history through verified transaction records, prioritizing those with documented reorder rates above 30%. Conduct sample testing against IEC 60268-21 standards for enclosure durability, weather resistance (if applicable), and alignment accuracy prior to full-scale ordering.

What Are the Best Line Array Box for Assembly Suppliers?

No qualified suppliers currently meet minimum benchmark thresholds for inclusion in this category based on available data. Absence of verifiable production metrics, certifications, and facility details prevents objective ranking. Procurement teams should exercise due diligence in initial screening to avoid engagement with non-compliant or under-resourced manufacturers.

Performance Analysis

While no suppliers are listed, historical trends indicate that established audio equipment manufacturers in Guangdong typically outperform in scalability and export readiness, while specialized workshops in Zhejiang excel in custom cabinet finishes and lightweight composite designs. Prioritize suppliers demonstrating ISO certification, documented on-time delivery rates (>95%), and proven experience in exporting to Tier-1 sound reinforcement brands. For complex configurations, require 3D CAD modeling support and physical prototype validation before mass production.

FAQs

How to verify line array box supplier reliability?

Validate certifications through issuing bodies and request audit trails covering material sourcing, joinery methods, and finish application. Evaluate real-world performance via reference projects or third-party acoustic testing reports. Focus on after-sales responsiveness and technical documentation completeness during assessment.

What is the average sampling timeline?

Standard sample production takes 20–30 days, depending on material availability and design complexity. Weatherproof or flyable configurations with integrated rigging may extend to 45 days. Air freight adds 5–10 days for international delivery.

Can suppliers ship line array boxes worldwide?

Yes, experienced manufacturers manage global logistics via FOB or CIF terms. Confirm container loading plans for palletized or nested configurations to optimize cubic space. Sea freight is standard for bulk orders; air shipping is viable for urgent samples or replacement parts.

Do manufacturers provide free samples?

Sample fees are typically charged but may be waived for confirmed orders exceeding 10 units. Expect sample costs to cover 40–60% of unit production expenses, including raw materials and labor. Refund policies vary and should be clarified pre-engagement.

How to initiate customization requests?

Submit detailed specifications including enclosure dimensions, driver layout, panel thickness (commonly 15–18mm plywood), corner protection type, and finish requirements (textured paint, carpet, or laminate). Reputable suppliers deliver 3D renderings within 72 hours and functional prototypes in 4–5 weeks.