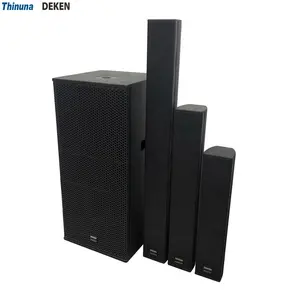

Line Array Cabinet Distributor

Top sponsor listing

Top sponsor listing

1/3

1/3

1/20

1/20

1/23

1/23

1/3

1/3

1/3

1/3

1/3

1/3

1/31

1/31

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/12

1/12

1/3

1/3

0

0

1/14

1/14

1/1

1/1

About line array cabinet distributor

Where to Find Line Array Cabinet Distributors?

China remains the central hub for professional audio equipment manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving global supply of line array cabinet systems. Guangdong, particularly the Guangzhou–Shenzhen corridor, hosts over 70% of China’s loudspeaker component suppliers, supported by advanced acoustic testing laboratories and rapid prototyping facilities. This region benefits from integrated electronics manufacturing ecosystems, enabling streamlined sourcing of drivers, crossover networks, and digital signal processors.

Zhejiang’s Ningbo and Hangzhou zones specialize in precision woodwork and structural metal fabrication, critical for durable, lightweight enclosures. These clusters leverage CNC machining, robotic welding, and automated finishing lines to maintain tight tolerances across high-volume production runs. Buyers gain access to vertically aligned supply chains—where raw plywood, aluminum extrusions, and rigging hardware are sourced within 30km—reducing material lead times by 25–40% compared to non-specialized regions. Typical advantages include MOQ flexibility (as low as 1 pair for custom configurations), lead times of 20–35 days for standard orders, and cost efficiencies of 18–25% due to localized component availability.

How to Choose Line Array Cabinet Distributors?

Apply these verification criteria when evaluating potential partners:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for consistent manufacturing processes. For exports to EU and North American markets, CE and RoHS compliance is mandatory to meet electromagnetic compatibility and hazardous substance regulations. Request test reports for enclosure durability (IEC 60268-21 compliance) and thermal performance under sustained load conditions.

Production Infrastructure Assessment

Evaluate core capabilities through documented evidence:

- Minimum 3,000m² factory area with dedicated assembly and acoustic testing zones

- In-house woodworking and metalworking facilities (CNC routers, powder coating lines)

- Engineering team comprising ≥8% of total staff for design validation and customization support

Cross-check facility size with monthly output capacity (target: 500+ cabinets/month) and on-time delivery performance (benchmark: ≥96%).

Procurement & Transaction Security

Utilize secure payment structures such as letter of credit or escrow services until product inspection is completed at destination. Review supplier transaction history for resolved disputes and warranty fulfillment rates. Pre-shipment sampling is strongly advised—conduct field tests on dispersion patterns, maximum SPL, and rigging safety under real-world suspension loads before scaling orders.

What Are the Best Line Array Cabinet Distributors?

No verified suppliers were found matching the current search criteria for "line array cabinet distributor." Ensure accurate categorization and spelling when sourcing; alternative terms such as “line array speaker manufacturer” or “professional audio system supplier” may yield more comprehensive results. When available, prioritize distributors with documented export experience to AV integrators, event production companies, or rental houses in target markets.

Performance Analysis

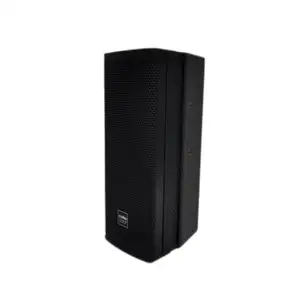

In mature audio equipment markets, leading distributors combine technical expertise with scalable logistics, offering pre-engineered solutions for touring, fixed installation, and outdoor applications. Key differentiators include adherence to L-Acoustics or Meyer Sound-compatible mechanical standards, use of Baltic birch plywood (≥15mm thickness), and integration of certified rigging systems (e.g., DLT, C-clamp, or omega bracket compatibility). For mission-critical deployments, verify finite element analysis (FEA) modeling of structural integrity and third-party lab verification of frequency response data.

FAQs

How to verify line array cabinet distributor reliability?

Audit certifications through official databases and request factory inspection reports from independent assessors. Evaluate responsiveness, technical documentation depth (user manuals, rigging schematics, CAD drawings), and after-sales service protocols including spare parts availability and firmware updates for active models.

What is the average sampling timeline?

Standard sample production takes 12–18 days. Custom finishes, driver configurations, or networked DSP integration extend timelines to 25–30 days. Allow 5–9 days for international express delivery depending on destination.

Can distributors ship globally?

Yes, experienced suppliers manage worldwide shipments via air or sea freight. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and packaging specifications (flight cases vs. flat-pack) to ensure safe transit. Full container loads (FCL) are recommended for large deployments to reduce per-unit shipping costs.

Do suppliers offer free samples?

Sample policies vary by order volume. Some waive fees for confirmed bulk purchases (typically 10+ units). Otherwise, expect to cover 40–60% of unit cost plus shipping, refundable upon order placement above minimum thresholds.

How to initiate customization requests?

Submit detailed requirements including cabinet dimensions, coverage angles (horizontal/vertical), finish type (textured paint, carpet, laminate), input panel configuration, and rigging geometry. Reputable partners provide engineering feedback within 48 hours and prototype builds within 3–4 weeks.