Line Array Empty Box Producer

About line array empty box producer

Where to Find Line Array Empty Box Producers?

China remains the global hub for professional audio equipment manufacturing, with key production clusters concentrated in Guangdong and Zhejiang provinces. These regions host vertically integrated facilities specializing in line array speaker enclosures, leveraging localized access to high-grade birch plywood, precision woodworking machinery, and surface treatment technologies. Zhongshan and Enping in Guangdong province are particularly notable for their concentration of audio cabinet manufacturers, offering scalable production from prototype to mass volume.

Suppliers in these industrial zones operate dedicated production lines equipped with CNC routers, multi-axis sanders, and automated coating systems, enabling consistent dimensional accuracy and finish quality. The proximity to material suppliers reduces component lead times by 15–25% compared to offshore alternatives. Buyers benefit from established ecosystems where design engineering, wood processing, hardware integration, and packaging occur within tightly coordinated networks, supporting average production lead times of 20–35 days for standard orders.

How to Choose Line Array Empty Box Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Material Capabilities

Confirm use of structural-grade materials such as 15–18mm Baltic birch plywood, known for rigidity and resonance control. Evaluate processing techniques: suppliers should employ dado joints, internal bracing, and robotic glue application for long-term durability under touring conditions. In-house capabilities in powder coating, water-based painting, or textured finishes (e.g., emery paint) indicate higher customization readiness.

Quality Assurance Metrics

Prioritize suppliers with documented on-time delivery rates exceeding 90% and reorder rates above 25%, indicating customer retention and process stability. While formal certifications like ISO 9001 may not be universally listed, consistent performance metrics—verified through transaction platforms—are strong proxies for reliability. Response times under 6 hours reflect operational responsiveness critical for iterative design or urgent reorders.

Customization & Compliance Readiness

Assess flexibility in size, suspension system design (e.g., flying points, rigging frames), logo engraving, color matching, and packaging. Suppliers offering reverse engineering services can replicate proprietary designs. For international buyers, confirm compatibility with regional safety standards such as CE or RoHS, especially if integrating electronics later. Waterproofing, UV-resistant coatings, and IP-rated sealing options are available from advanced producers.

Procurement Safeguards

Utilize secure payment terms with milestone verification, particularly for custom tooling or large runs. Request physical or digital samples before full-scale production to validate build quality and finish consistency. Cross-reference product listings with company revenue data and order history to assess scalability and market presence.

What Are the Leading Line Array Empty Box Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Zhongshan Tigris Technology Co., Ltd. | Guangdong, CN | Line array cabinets, passive speakers | US $400,000+ | 96% | 27% | ≤6h | Color, material, size, logo, packaging, label, graphic | 2–4 sets |

| Guangzhou Tengge Audio Equipment Co., Ltd. | Guangdong, CN | Line array boxes, sound systems | US $8,000+ | 100% | <15% | ≤6h | Limited (product-focused) | 2–8 pieces |

| Guangzhou T.i Audio Co., Ltd. | Guangdong, CN | Professional audio systems, empty cabinets | US $490,000+ | 86% | 60% | ≤5h | Extensive: material, size, logo, waterproofing, suspension, power distribution, digital mixer integration | 1–4 pieces/sets |

| Enping Aoyang Audio Technology Co., Ltd. | Guangdong, CN | Active/passive line arrays, custom enclosures | US $20,000+ | 60% | 28% | ≤16h | High: biamp routing, temperature sensors, motorized faders, scanner integration, shape modification | 2–5 pieces |

| Guangzhou Suiyu Technology Co., Ltd. | Guangdong, CN | Wholesale line array components, loudspeaker enclosures | US $130,000+ | 93% | <15% | ≤10h | Standard customization: size, logo, packaging | 8 units |

Performance Analysis

Guangzhou T.i Audio stands out with a 60% reorder rate and deep customization capacity, suggesting strong client satisfaction despite moderate on-time delivery (86%). Zhongshan Tigris combines high delivery reliability (96%) with substantial transaction volume, making it suitable for stable mid-to-large orders. Guangzhou Tengge achieves perfect on-time performance but reports low reorder activity, potentially indicating transactional rather than relationship-based engagement. Enping Aoyang offers niche engineering features but lags in delivery consistency (60%), warranting closer monitoring. Guangzhou Suiyu serves high-volume buyers with standardized designs, supported by robust fulfillment (93%) and competitive pricing at scale.

FAQs

What materials are commonly used in line array empty boxes?

Baltic birch plywood (15–18mm) is standard due to its strength-to-weight ratio and acoustic properties. Some suppliers offer MDF for budget applications or carbon fiber composites for premium lightweight enclosures.

What is the typical MOQ for empty line array cabinets?

Minimum order quantities range from 1 set for custom prototypes to 8 units for wholesale pricing. Dual-10" and dual-12" configurations are most common, with prices starting around $100–$225 per unit depending on size and finish.

How long does production and shipping take?

Manufacturing lead time averages 20–30 days after design approval. Air freight delivers samples in 7–10 days; sea freight for bulk orders takes 25–40 days depending on destination port and customs clearance.

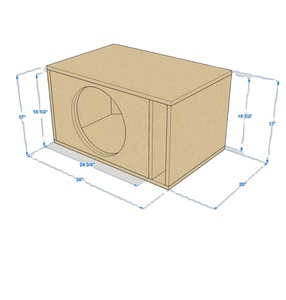

Can suppliers provide 3D drawings or CAD files?

Yes, leading suppliers offer DWG, DXF, or STEP files for rigging layout and system simulation. Most respond to technical inquiries within 5–10 hours with dimensioned drawings upon request.

Are free samples available?

Sample policies vary. Some suppliers deduct sample costs from future orders above 4–8 units. Others charge full sample price, typically 1.5x unit cost, which may be negotiable based on projected volume.