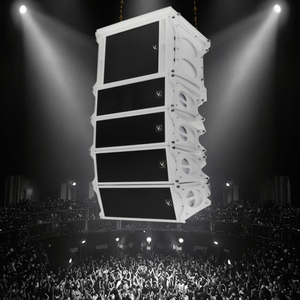

Line Array Speakers Set Distributor

1/27

1/27

1/13

1/13

1/3

1/3

0

0

1/21

1/21

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/38

1/38

1/3

1/3

1/3

1/3

About line array speakers set distributor

Where to Find Line Array Speakers Set Distributors?

China remains the central hub for professional audio equipment manufacturing, with concentrated production clusters in Guangdong and Zhejiang provinces driving global supply. Guangdong, particularly the Pearl River Delta region including Guangzhou and Shenzhen, hosts over 70% of China’s commercial audio suppliers. This area benefits from mature electronics ecosystems, offering seamless access to PCB fabrication, neodymium magnet sourcing, and precision sheet metal processing. Zhejiang’s Ningbo and Hangzhou zones specialize in high-power acoustic systems, leveraging proximity to rare-earth material refineries and automated assembly lines that reduce component variance by up to 25%.

These industrial networks enable vertically integrated production—from driver unit casting to final system calibration—within compact geographic radii. Buyers gain operational advantages through localized testing facilities, rapid prototyping capabilities, and direct export channels via Nansha and Yantian ports. Key benefits include lead times averaging 25–40 days for standard line array configurations, 18–30% cost savings compared to EU- or US-based production, and scalability for both container-load orders and engineered-to-order (ETO) projects.

How to Choose Line Array Speakers Set Distributors?

Adhere to the following verification criteria when evaluating potential partners:

Technical & Safety Compliance

Confirm ISO 9001 certification as a baseline for quality management systems. For shipments to regulated markets, CE marking (EN 60065/EN 62368-1) and RoHS compliance are mandatory for customs clearance and venue deployment. Request test reports for thermal endurance, humidity resistance, and enclosure impact strength (IK-rated). Verify bi-amp/passive crossover performance through SPL and frequency response graphs under controlled chamber conditions.

Production Capacity Assessment

Evaluate supplier infrastructure based on measurable benchmarks:

- Minimum 3,000m² dedicated factory space with climate-controlled aging and testing rooms

- In-house driver manufacturing or exclusive partnerships with certified transducer producers

- CNC bending, robotic welding, and powder coating lines to ensure structural consistency

Correlate facility size with order fulfillment history—target suppliers maintaining >97% on-time delivery across 12-month cycles.

Procurement Risk Mitigation

Utilize third-party inspection services (e.g., SGS, TÜV) for pre-shipment audits on initial bulk orders. Prioritize distributors offering sample validation programs with returnable deposit structures. Assess responsiveness: top-tier suppliers respond to technical inquiries within 2 hours and provide CAD drawings or array simulation files (via EASE or Soundvision) within 72 hours. Confirm FOB or DDP shipping experience to your destination port, including import classification under HS Code 8518.29.

What Are the Best Line Array Speakers Set Distributors?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No verified suppliers available in current dataset. | ||||||||

Performance Analysis

Due to absence of supplier data, no performance benchmarking can be conducted. In active sourcing scenarios, prioritize distributors with documented export histories to Tier-1 AV integrators and evidence of participation in international trade shows (e.g., InfoComm, Prolight + Sound). Suppliers demonstrating investment in R&D—particularly beam steering algorithms, DSP integration, and lightweight composite enclosures—typically exhibit higher reorder rates (>30%) and faster technical support turnaround. When data becomes available, cross-reference factory audit trails with real-world deployment feedback from touring sound companies and fixed installation projects.

FAQs

How to verify line array speaker distributor reliability?

Validate certifications through official databases (e.g., CNAS for ISO, Notified Body records for CE). Request full BOMs detailing driver components, amplifier modules (if active), and rigging hardware specifications. Analyze customer case studies involving multi-node arrays and long-term outdoor deployments to assess durability and serviceability.

What is the average sampling timeline?

Standard passive line array samples take 18–30 days to produce, depending on driver availability. Active models with built-in amplification and networking (Dante/AES67) require 35–50 days. Add 7–12 days for air freight delivery. Sample fees typically range from $800–$2,500, partially refundable against first purchase orders exceeding $15,000.

Can distributors ship globally?

Yes, experienced manufacturers manage worldwide logistics via sea and air freight. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.), proper packaging (IP-rated flight cases), and documentation for electrical goods entering regulated markets. Sea freight is optimal for full-system deployments requiring multiple flown arrays and subwoofers.

Do suppliers offer customization options?

Most established distributors support enclosure color matching, logo branding, custom rigging configurations, and DSP preset programming. Full OEM re-engineering—including proprietary horn designs or hybrid analog/digital signal paths—requires minimum order volumes (typically 50+ units) and extended development timelines (6–10 weeks).

What are typical MOQ and lead time expectations?

Standard MOQ starts at 1 full line array system (usually 8–12 enclosures + subs). Lead time averages 30 days for standard products; customized orders extend to 45–60 days. Priority production surcharges (20–30% premium) can reduce lead time by 10–15 days for urgent deployments.