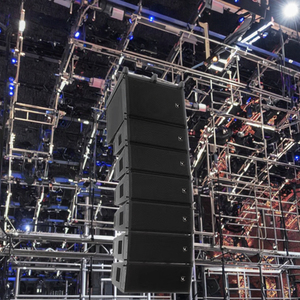

Line Array Speakers

Top sponsor listing

Top sponsor listing

1/20

1/20

1/13

1/13

1/32

1/32

1/30

1/30

1/3

1/3

1/3

1/3

1/27

1/27

1/17

1/17

1/18

1/18

1/36

1/36

1/3

1/3

1/28

1/28

0

0

1/3

1/3

1/2

1/2

1/3

1/3

About line array speakers

Where to Find Line Array Speaker Suppliers?

China serves as the central hub for professional audio equipment manufacturing, with key production clusters in Guangdong and Zhejiang provinces. Shenzhen and Guangzhou in Guangdong host over 70% of China’s pro-audio exporters, supported by mature supply chains for transducers, amplifiers, and structural components. These regions offer integrated ecosystems where raw material sourcing, CNC fabrication, acoustic testing, and export logistics operate within tightly coordinated networks, enabling rapid prototyping and scalable production.

The industrial infrastructure supports both standardized and engineered-to-order line array systems. Manufacturers leverage localized access to neodymium magnets, compression drivers, and high-strength aluminum rigging components, reducing component lead times by 25–40% compared to offshore alternatives. Buyers benefit from average production cycles of 15–30 days for standard configurations, with customization options spanning horn profiles, enclosure materials, and integrated DSP processing. Monthly output across major suppliers ranges from 500 to 2,000 units, accommodating bulk orders for touring sound companies and fixed installations.

How to Choose Line Array Speaker Suppliers?

Procurement decisions should be guided by technical capability, quality assurance, and transaction reliability:

Technical Compliance

Verify adherence to international standards such as IEC 60268-21 (loudspeaker performance) and RoHS for material safety. For export to regulated markets, confirm CE or FCC certification on active models. Request test reports detailing sensitivity, frequency response, and maximum SPL, particularly for dual-10", 12", and 15" configurations commonly used in live sound applications.

Production Capability Audits

Assess core operational metrics:

- Minimum 3,000m² factory area for consistent assembly line operations

- In-house capabilities in wood/plywood enclosure fabrication, powder coating, and electronic integration

- Dedicated R&D teams supporting acoustic simulation and system tuning

Cross-reference online revenue data and reorder rates (>20% indicates customer retention) to evaluate service quality and product reliability.

Transaction Safeguards

Prioritize suppliers with documented quality management systems (ISO 9001 preferred). Use secure payment methods with milestone verification, especially for customized builds exceeding $10,000. Conduct sample evaluations to validate build quality, focusing on cabinet durability, driver alignment, and thermal performance under sustained load. Confirm packaging integrity for international shipping, including corner protectors and moisture-resistant wrapping.

What Are the Best Line Array Speaker Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope |

|---|---|---|---|---|---|---|---|

| INSIGAI Technology Shenzhen LTD | Shenzhen, CN | Sound Equipment/Speaker (202), Audio Sound Equipment (105) | 98% | ≤1h | 26% | US $350,000+ | Color, size, logo, structure, power plug, amplifiers, subwoofers, assembly |

| Zhongshan Tigris Technology Co., Ltd. | Zhongshan, CN | Line Array Speakers, Active Arrays | 98% | ≤6h | 24% | US $440,000+ | Color, material, size, logo, packaging |

| L-Solution Audio Engineering Co., Ltd | Guangdong, CN | HDL Series, Powered Arrays, Subwoofers | 89% | ≤2h | 26% | US $240,000+ | Material, size, logo, crossover, HF driver, magnet type |

| Guangzhou Yazoo Pro-Audio Co., Ltd. | Guangzhou, CN | Dual 10"/12"/15" Arrays, OEM Amplifiers | 97% | ≤1h | 18% | US $50,000+ | Color, size, logo, packaging, graphic design |

Performance Analysis

INSIGAI Technology leads in responsiveness and customization breadth, offering full-system integration services including amplifier matching and acoustic modeling. Zhongshan Tigris demonstrates strong commercial traction with a high reorder rate and extensive product range covering passive and active arrays. L-Solution provides engineering depth in driver-level customization but lags slightly in delivery consistency. Guangzhou Yazoo offers competitive pricing on mid-tier models but has lower repeat order volume, suggesting niche market positioning. Buyers seeking turnkey solutions should prioritize suppliers with sub-2-hour response times and proven experience in system simulation and rigging design.

FAQs

What is the typical MOQ for line array speakers?

Standard MOQ ranges from 1–2 pieces per model for sample testing, with bulk pricing activated at 4–10 sets. Some suppliers waive MOQ for first-time buyers placing full-container orders.

How long does production and shipping take?

Lead time averages 15–25 days for custom orders, with an additional 7–14 days for sea freight to North America or Europe. Air shipping reduces transit to 5–8 days but increases costs by 60–100%.

Can suppliers customize speaker enclosures and branding?

Yes. Most manufacturers support CNC-machined baffle designs, client-specific colors, logo silkscreening, and custom flight cases. Structural modifications (e.g., rigging point configuration) require engineering validation and may extend lead time by 5–10 days.

Do suppliers provide technical documentation?

Reputable vendors supply product datasheets, rigging templates, EASE file support, and amplifier pairing guides. Verify inclusion of SPL charts, dispersion angles, and recommended crossover points before finalizing orders.

Are samples available before bulk ordering?

Sample units are typically offered at 1.5x list price, refundable against future orders. Active models may include trial DSP presets and remote monitoring setup upon request.