Line Array Waveguide Producer

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/18

1/18

1/3

1/3

1/3

1/3

1/3

1/3

1/26

1/26

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/2

1/2

0

0

1/12

1/12

1/3

1/3

1/3

1/3

1/3

1/3

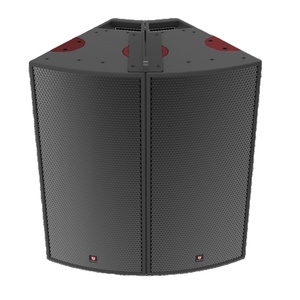

About line array waveguide producer

Where to Find Line Array Waveguide Producers?

China remains the central hub for professional audio component manufacturing, with key production clusters in Guangdong and Zhejiang provinces. Foshan and Guangzhou in Guangdong host specialized suppliers of line array waveguides, benefiting from mature ecosystems in professional audio hardware and smart home integration. These regions offer vertically integrated supply chains—spanning injection molding, acoustic engineering, and precision assembly—enabling rapid prototyping and scalable output. Proximity to ports like Guangzhou Nansha facilitates efficient export logistics, reducing transit times for international buyers by 10–15% compared to inland manufacturing zones.

Suppliers in these clusters typically operate dedicated production lines for waveguide components, utilizing ABS, polycarbonate, and composite materials optimized for sound dispersion and structural durability. Monthly production capacities range from 5,000 to over 20,000 units per facility, supporting both bulk procurement and low-volume custom orders. The integration of CNC machining, 3D modeling, and in-house tooling allows for tight tolerances (±0.1mm) and consistent acoustic performance across batches.

How to Choose Line Array Waveguide Suppliers?

Procurement decisions should be guided by technical capability, quality assurance, and operational reliability:

Production Infrastructure

Prioritize suppliers with documented in-house manufacturing capabilities, including injection molding, compression driver integration, and acoustic testing facilities. Facilities exceeding 3,000m² with dedicated R&D teams are better equipped to handle custom designs and volume scaling. Confirm ownership of tooling and molds to ensure control over design replication and lead time.

Quality Management Systems

While formal certifications (ISO 9001, CE, RoHS) are not explicitly stated in available data, evaluate compliance through alternative indicators:

- On-time delivery rates above 90% indicate reliable internal process control

- Response times under 12 hours reflect operational responsiveness

- Reorder rates exceeding 15% suggest customer satisfaction with product consistency

Request material datasheets and conduct sample testing for frequency response, phase alignment, and mechanical fit before mass production.

Transaction and Customization Capabilities

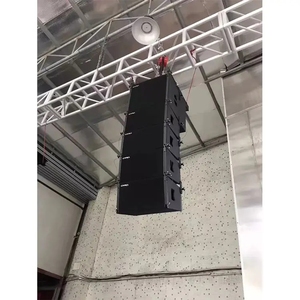

Assess flexibility in MOQs, pricing tiers, and customization scope. Leading suppliers support configurations in throat size (1", 1.4", 2"), dispersion angles (70°–120°), and mounting interfaces. Some offer color, logo imprinting, and packaging modifications. Verify compatibility with common line array platforms (e.g., VRX, MLA, d&b) through technical drawings or CAD files prior to ordering.

What Are the Best Line Array Waveguide Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Foshan Yinchi Electronics Co., Ltd. | Foshan, CN | Sound Equipment, Amplifiers, Speaker Components | US $40,000+ | 82% | ≤12h | 15% | 1–2 pieces | $30–$75 |

| Foshan Kaweisen Smart Home Technology Co., Ltd. | Foshan, CN | Audio Accessories, Horn Waveguides, Lighting Hardware | US $40,000+ | 92% | ≤1h | 18% | 10 pieces | $11.50–$31.50 |

| Guangzhou Suiyu Technology Co., Ltd. | Guangzhou, CN | Professional Audio, Fasteners, Tool Cases | US $130,000+ | 92% | ≤10h | <15% | 4–8 pieces | $31–$1,300 |

| Milimike Smart Home Yangzhou Co., Ltd. | Yangzhou, CN | Horn Waveguides, Pipe Clamps, Lighting Hardware | US $9,000+ | 100% | ≤2h | <15% | 10 pieces | $22–$35 |

| Hangzhou Grandix Electronic Co. Ltd. | Hangzhou, CN | Custom Audio Components, Tweeter Waveguides | US $410,000+ | 100% | ≤6h | 15% | 100 pieces | $9.50–$13.49 |

Performance Analysis

Hangzhou Grandix stands out with the highest online revenue and perfect on-time delivery, offering the lowest unit prices due to high-volume efficiency. Its 100-piece MOQ suits large-scale integrators seeking cost-optimized components. Foshan Kaweisen combines strong delivery performance (92%) with the fastest average response time (≤1h), ideal for time-sensitive procurement cycles. Milimike Smart Home achieves 100% on-time fulfillment despite lower reorder rates, indicating reliability in execution but potential gaps in long-term client retention. Guangzhou Suiyu offers premium-priced solutions aligned with full line array systems, suggesting higher integration complexity. Foshan Yinchi provides the most flexible MOQs (down to 1 piece), making it suitable for prototyping or replacement part sourcing.

FAQs

How to verify line array waveguide supplier reliability?

Evaluate on-time delivery history, response speed, and transaction volume as proxies for operational stability. Request product specifications, material certifications, and test reports. Conduct factory audits via video tour to confirm in-house production and quality control processes.

What is the typical lead time for waveguide components?

Standard orders are fulfilled within 15–25 days after payment confirmation. Custom designs with new molds may require 30–45 days, including sampling and approval phases.

Can suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples (cost recoverable against future orders), while others charge full price. Expect shipping fees to apply. Sample costs typically range from $30–$100 depending on complexity.

Do manufacturers support OEM/ODM services?

Yes, several suppliers—including Hangzhou Grandix—offer customization in color, branding, packaging, and dimensional specifications. Minimum order thresholds apply, typically starting at 500 units for full OEM configurations.

What are common packaging and shipping methods?

Products are usually packed in cartons with foam or bubble wrap protection. Shipping options include air freight (7–10 days) and sea freight (25–35 days). FOB terms are standard; CIF can be arranged upon request.