Line Follower Robot Using Arduino

1/3

1/3

0

0

1/2

1/2

1/20

1/20

1/1

1/1

1/3

1/3

1/3

1/3

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/14

1/14

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

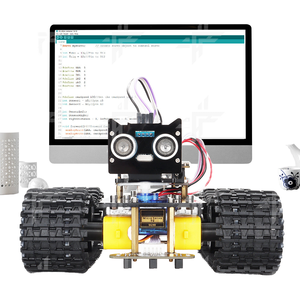

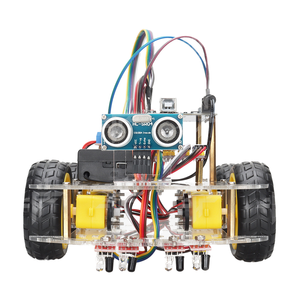

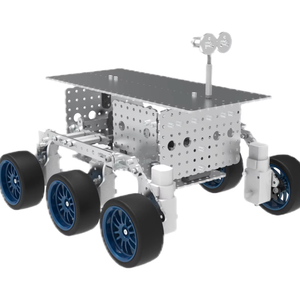

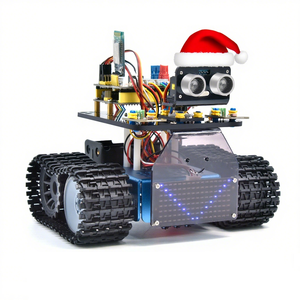

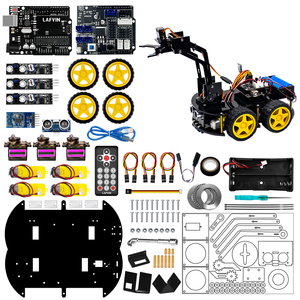

About line follower robot using arduino

Where to Find Line Follower Robot Using Arduino Suppliers?

China remains the central hub for electronics and robotics manufacturing, with key production clusters in Shenzhen, Beijing, and surrounding Guangdong and Hebei regions. These zones host vertically integrated supply chains specializing in microcontroller-based educational kits, robotics platforms, and IoT-enabled devices. Shenzhen’s ecosystem excels in rapid prototyping and small-batch customization, supported by dense networks of component suppliers, PCB fabricators, and firmware developers operating within compact industrial parks.

The region enables efficient sourcing of Arduino-compatible robotics solutions due to proximity to semiconductor distributors, motor manufacturers, and sensor module producers. This localization reduces component lead times by 20–30% compared to offshore alternatives. Suppliers benefit from streamlined assembly processes, automated testing stations, and modular design frameworks that allow quick adaptation of line follower robot configurations. Buyers gain access to scalable production runs—from pilot batches of 10 units to container-scale orders—within typical lead times of 15–25 days after sample approval.

How to Choose Line Follower Robot Using Arduino Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify compatibility with standard Arduino platforms (Uno, Nano, Mega) and integration of essential sensors such as infrared array modules for line detection. Confirm inclusion of motor drivers, chassis designs optimized for traction and balance, and support for open-source coding environments like Arduino IDE or Scratch-based interfaces for STEM applications. CE, RoHS, and FCC certifications should be available upon request, particularly for export to regulated markets.

Production and Customization Capacity

Assess infrastructure through documented capabilities:

- Minimum facility size of 1,000m² indicating dedicated production lines

- In-house R&D teams capable of modifying code libraries, adjusting sensor sensitivity, or reconfiguring mechanical layouts

- Customization options including color, labeling, packaging, and preloaded firmware

Cross-reference response time metrics (target ≤5 hours) and on-time delivery rates (preferably ≥95%) as indicators of operational reliability.

Transaction Security & Quality Assurance

Prioritize suppliers offering verifiable quality control protocols, including functional testing of sensor arrays and motor calibration per unit. Utilize secure payment mechanisms such as escrow services where release is contingent upon product validation. Request samples before bulk ordering to evaluate build quality, wheel alignment precision, and responsiveness of line-tracking algorithms. Analyze reorder rates as a proxy for customer satisfaction—rates above 20% suggest consistent performance and service reliability.

What Are the Best Line Follower Robot Using Arduino Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kechen Technology Co., Ltd | Shenzhen, CN | Drones Accessories, Microcontrollers, FPGA Boards | US $40,000+ | 92% | ≤5h | 22% | No | 2–10 pieces |

| Robottime (Beijing) Technology Co., Ltd. | Beijing, CN | Robotics Kits, Science & Engineering Toys | US $300+ | 100% | ≤6h | - | No | 1–2 sets |

| Shenzhen Keyes DIY Robot Co., Ltd. | Shenzhen, CN | STEM Kits, Programmable Cars, OEM Mechanical Arms | US $280,000+ | 99% | ≤2h | <15% | Yes | 1 piece/set |

| Shenzhen Hong Shu Yuan Technology Co., Ltd. | Shenzhen, CN | 4WD Robotics Chassis, ESP32 Projects, Education Kits | US $140,000+ | 92% | ≤9h | 30% | Yes | 2 sets |

| Acebott Stem Education Tech Co., Ltd. | Shenzhen, CN | STEM Starter Kits, Smart Vehicles, Tracked Robots | US $70,000+ | 100% | ≤3h | 21% | Yes | 2 pieces |

Performance Analysis

Shenzhen Keyes DIY Robot Co., Ltd. stands out with high online revenue (US $280,000+), near-perfect on-time delivery (99%), and sub-2-hour response times, indicating robust internal coordination. Despite a lower reorder rate, its verified customization capacity supports tailored branding and technical adjustments. Robottime and Acebott achieve 100% on-time delivery, reflecting strong logistics management, while Shenzhen Hong Shu Yuan leads in customer retention with a 30% reorder rate—suggesting high satisfaction with product consistency and post-sale support. Suppliers based in Shenzhen dominate responsiveness and customization flexibility, making them ideal for buyers requiring iterative development or private-label solutions.

FAQs

How to verify line follower robot supplier reliability?

Cross-check declared certifications (CE, RoHS) and request evidence of functional testing procedures. Review transaction history metrics such as on-time delivery and reorder rates. Conduct video audits of production areas if physical visits are not feasible, focusing on assembly line organization and QC checkpoints.

What is the average sampling timeline?

Standard sample production takes 7–14 days, depending on customization needs. Shipping via express courier adds 5–8 business days internationally. Complex modifications involving firmware rewriting or structural redesign may extend timelines to 20 days.

Can suppliers ship globally?

Yes, most suppliers offer international shipping via air freight or consolidated sea containers. Confirm Incoterms (e.g., FOB Shenzhen, CIF Rotterdam) early in negotiations. Ensure compliance with import regulations related to electronic components and battery-powered devices in the destination market.

Do suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against future orders, typically when MOQ thresholds are met. Expect to pay full freight costs unless otherwise negotiated. Free samples are rare but possible for high-volume prospects demonstrating long-term potential.

How to initiate customization requests?

Submit detailed specifications covering chassis material (acrylic vs. ABS), wheel type (rubber-treaded or omni-directional), microcontroller model (Arduino Nano clone vs. original), and software requirements (pre-installed PID algorithm, Bluetooth connectivity). Reputable suppliers respond with updated quotations and CAD previews within 48–72 hours.