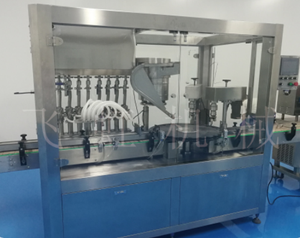

Linear Bottle Capping Machine

Top sponsor listing

Top sponsor listing

1/17

1/17

1/6

1/6

1/13

1/13

1/24

1/24

1/14

1/14

1/22

1/22

1/25

1/25

1/8

1/8

1/25

1/25

1/20

1/20

About linear bottle capping machine

Where to Find Linear Bottle Capping Machine Suppliers?

China remains the dominant hub for linear bottle capping machine manufacturing, with key production clusters in Jiangsu, Zhejiang, and Jiangxi provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, automated assembly lines, and robust supply chains for packaging machinery components. Jiangsu province, in particular, is home to advanced CNC machining facilities and servo-driven automation specialists, enabling high-precision construction of capping heads and conveyor integration.

The concentration of technical expertise and component suppliers within 50km radii allows manufacturers to maintain lean production cycles and rapid prototyping capabilities. This localization reduces lead times for standard models to 30–45 days and supports cost efficiency, with production expenses typically 20–30% lower than comparable Western-built equipment. Buyers benefit from scalable output capacity, access to modular designs, and the ability to integrate capping systems into full-line bottling solutions including filling and labeling.

How to Choose Linear Bottle Capping Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Confirm adherence to international quality management standards such as ISO 9001. For export markets, CE certification is essential for compliance with European safety directives. Request documentation on material specifications (e.g., stainless steel grades used in contact parts), torque control systems, and sealing performance testing under variable cap types (screw, snap, child-resistant).

Production Capacity Verification

Assess infrastructure indicators to ensure scalability and consistency:

- Minimum factory area of 3,000m² for dedicated assembly lines

- In-house engineering teams capable of customizing torque settings, bottle size ranges (1ml–20L), and integration with upstream/downstream machinery

- On-time delivery rate exceeding 95% as an indicator of operational reliability

Cross-reference self-reported metrics with historical transaction data where available.

Procurement Safeguards

Utilize secure payment methods such as third-party escrow until post-delivery inspection is completed. Prioritize suppliers offering sample units for functional testing—particularly for non-standard cap formats or viscous product applications. Evaluate responsiveness (target ≤2 hours) and reorder rates as proxies for customer satisfaction and after-sales support effectiveness.

What Are the Best Linear Bottle Capping Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range Example | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shanghai Honor Industry Co., Ltd. | Filling Machines, Labeling Machines, Capping Machines | US $380,000+ | 100% | ≤1h | 37% | Yes | 15ml–20L bottles; pneumatic/honey/piston-based filling integration | $2,300–13,600 |

| Zhangjiagang Beyond Machinery Co., Ltd. | Filling Machines, Packaging Line, Water Treatment Machinery | - | 100% | ≤1h | 50% | Limited | 5-gallon water bottles; 3-in-1 modular systems | $3,000–$10,000 |

| Haolian Machinery Co., Ltd. | Labeling Machines, Filling Machines, Capping Machines | US $100,000+ | 100% | ≤1h | 18% | Yes | Multiple configurations across liquid types | Not specified |

| Zhangjiagang Excellent Technology Co., Ltd. | Filling Machines, Extrusion Blow Molding Machines | - | 100% | ≤5h | - | Limited | 1L–20L lube, motor oil, jerrycans; inner/outer cap systems | $8,000–$18,000 |

| Changzhou Jerry Packaging Technology Co., Ltd. | Capping Machines, Labeling Systems, Packaging Machinery | US $160,000+ | 66% | ≤3h | 20% | Yes | Semi-automatic to full-auto; 1ml–5000ml; Coriolis metering | $1,600–$91,000 |

Performance Analysis

Shanghai Honor Industry stands out with strong reorder activity (37%) and comprehensive multi-machine integration capabilities, making it suitable for buyers seeking turnkey filling and capping lines. Zhangjiagang Beyond Machinery demonstrates high customer retention (50% reorder rate), indicating strong post-sale reliability despite limited customization visibility. All top-tier suppliers report 100% on-time delivery except Changzhou Jerry, whose 66% rate may signal logistical or production bottlenecks. Suppliers based in Jiangsu and Shanghai offer faster response times (≤1 hour), enhancing communication efficiency during technical discussions and order tracking.

FAQs

What certifications should linear bottle capping machine suppliers have?

ISO 9001 is the baseline for quality management. CE marking is required for compliance in European markets. Additional validation through machinery safety directives (e.g., EU 2006/42/EC) ensures adherence to mechanical and electrical safety standards.

What is the typical MOQ and lead time?

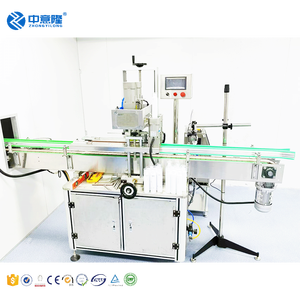

Minimum order quantity is generally 1 set, allowing for low-volume trials or single-unit integration. Lead times range from 30 to 45 days for standard configurations. Customized systems with specialized grippers, vision alignment, or IoT monitoring may extend delivery to 60 days.

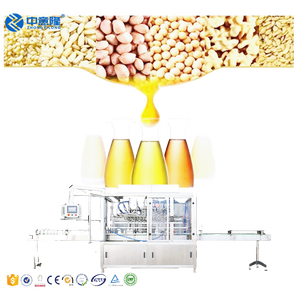

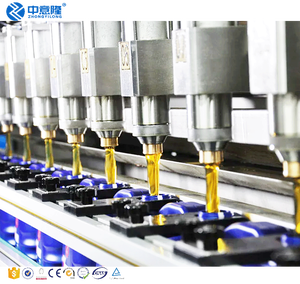

Can these machines handle different cap types and sizes?

Yes, most suppliers offer adjustable chuck heads or quick-change tooling for screw caps, pump sprayers, flip-tops, and induction seals. Customization options include programmable torque settings (0.5–25 N·cm) and changeover kits for varying bottle neck finishes.

Do suppliers provide machine validation and installation support?

Many offer remote commissioning via video guidance. Some provide on-site technician deployment at additional cost. Pre-shipment testing reports—including no-load operation, capping accuracy, and leak testing—are commonly available upon request.

How does pricing vary across models?

Entry-level semi-automatic units start around $1,600. Fully automatic inline systems with servo controls and multi-head cappers range from $8,000 to $18,000. High-speed, integrated lines with Coriolis mass flow control or nitrogen purging can exceed $80,000 depending on complexity.