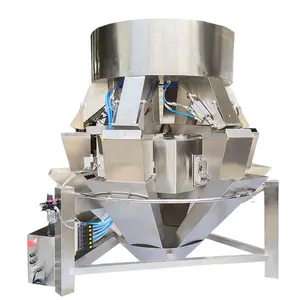

Linear Multihead Weigher

CN

CN

CN

CN

CN

CN

About linear multihead weigher

Where to Find Linear Multihead Weigher Suppliers?

China remains the global epicenter for linear multihead weigher manufacturing, with key industrial clusters in Shanghai, Guangdong, and Henan provinces driving innovation and scale. Shanghai-based suppliers leverage proximity to high-tech R&D centers and advanced automation ecosystems, enabling integration of precision weighing systems with packaging lines. Guangdong’s Pearl River Delta region hosts specialized machinery exporters with mature supply chains for servo motors, load cells, and stainless-steel fabrication, reducing component lead times by 20–30%. Henan’s Zhengzhou hub focuses on cost-efficient production of mid-range industrial weighers, supported by regional logistics networks that facilitate rapid export processing.

These clusters offer vertically integrated manufacturing capabilities—from CNC machining and sheet metal fabrication to final assembly—allowing suppliers to maintain tight tolerances (±0.1g to ±2g accuracy) and deliver standard configurations within 30–45 days. Buyers benefit from localized access to engineering talent, calibration laboratories, and third-party testing facilities. The concentration of suppliers also enables competitive pricing, with typical unit costs ranging from $600 for entry-level 4-head models to over $20,000 for high-speed, fully automated systems with CE certification and anti-sticky feeding mechanisms.

How to Choose Linear Multihead Weigher Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical reliability, production capacity, and transactional transparency.

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE marking for European market compliance and ISO 9001-certified quality management systems. Request documentation for calibration procedures, material certifications (e.g., SUS304 stainless steel contact parts), and electrical safety testing. For food, pharmaceutical, or chemical applications, confirm IP65-rated enclosures and compliance with hygiene design principles.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area supporting dedicated assembly lines for combination weighers

- In-house engineering teams capable of customizing hopper configurations, vibration feeders, and control software (PLC/HMI)

- Integration capability with downstream packaging machines (e.g., premade pouch fillers, stick pack machines)

- Cross-reference on-time delivery performance (target ≥95%) and response time metrics (ideally ≤7 hours) as indicators of operational efficiency

Customization & Transaction Safeguards

Confirm availability of customization options including weigh head count (3–10 heads), voltage specifications (220V/380V), language interfaces, and communication protocols (RS485, Ethernet). Utilize secure payment methods with milestone-based disbursements tied to production progress. Prioritize suppliers offering sample units or video demonstrations of machine operation under real-world conditions before full-scale orders.

What Are the Best Linear Multihead Weigher Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shanghai Weeshine Machinery Co., Ltd. | Shanghai, CN | Film Roll Machineries, Premade Pouch Systems | 83% | ≤7h | 40% | US $90,000+ | $600–3,200 | 1 set |

| Zhengzhou Jide Machinery Co., Ltd. | Henan, CN | Filling Machines (172), Packaging Lines | 100% | ≤1h | - | - | $3,500–15,000 | 1 set |

| FAIR PACK MACHINERIES PRIVATE LIMITED | Gujarat, IN | Multi-Function Packaging Machines (202) | - | ≤6h | - | - | $4,500–23,000 | 1 unit |

| Guangdong Kenwei Intellectualized Machinery Co., Ltd. | Guangdong, CN | Conveyor Weighers, Filling Lines | 100% | ≤7h | 33% | US $110,000+ | $4,500–9,460 | 1 set |

| Guangdong High Dream Intellectualized Machinery Co., Ltd. | Guangdong, CN | Anti-Sticky Feeders, Bucket Scales | 100% | ≤10h | <15% | US $1,000+ | $5,000–26,300 | 1–2 sets |

Performance Analysis

Zhengzhou Jide and Guangdong Kenwei demonstrate strong operational discipline with 100% on-time delivery records and robust product portfolios aligned with automated packaging workflows. Kenwei stands out with a 33% reorder rate and extensive customization support for bag size, target weight, and labeling integration. Shanghai Weeshine offers the broadest price range, catering to budget-conscious buyers with sub-$1,000 models while maintaining a high customer retention rate (40%). FAIR PACK MACHINERIES targets premium segments with high-capacity, CE-compliant systems priced above $20,000, though reorder data is unavailable. High Dream differentiates through niche anti-sticky designs but has lower online transaction volume and higher minimum order thresholds for select models.

FAQs

What is the typical lead time for linear multihead weighers?

Standard models are typically delivered within 30–45 days after order confirmation. Customized systems with specific voltage, software, or integration requirements may require 50–70 days, depending on complexity and component availability.

Do suppliers provide calibration and technical support?

Most established suppliers include factory calibration and basic operational training. Remote troubleshooting via video guidance is commonly offered. For on-site installation or advanced training, additional fees usually apply and should be clarified during negotiation.

Can linear multihead weighers handle sticky or fragile products?

Yes, specialized variants with non-stick coatings, adjustable vibration intensity, and soft-drop discharge mechanisms are available. Suppliers like Guangdong High Dream explicitly list anti-sticky features for items such as cheese, gummies, or coated seeds.

What are common customization options?

Buyers can typically modify the number of weighing heads (3–10), hopper material (stainless steel grade), control panel language, power supply, and interface with vertical form-fill-seal or premade pouch machines. Some suppliers offer 3D mockups and software simulations upon request.

Are samples available before bulk ordering?

Sample policies vary. Some suppliers offer functional demos via video or provide test runs with client-supplied materials. Physical samples may incur partial cost recovery, especially for high-value models, but are often credited toward subsequent orders.