Linking Machine Distributor

1/22

1/22

1/33

1/33

1/10

1/10

1/29

1/29

1/31

1/31

1/30

1/30

1/14

1/14

1/13

1/13

About linking machine distributor

Where to Find Linking Machine Suppliers?

China remains the dominant global hub for linking machine manufacturing, with key production clusters in Anhui, Henan, and Hebei provinces. These regions host vertically integrated facilities specializing in textile, sausage, and fence-linking machinery, leveraging localized supply chains to reduce component costs by 15–25% compared to non-specialized manufacturers. Hefei and Zhengzhou serve as central logistics nodes, enabling efficient export distribution across Asia, Europe, and North America.

The industrial ecosystems support rapid prototyping and scalable production, with many suppliers operating end-to-end manufacturing lines—from CNC machining and servo integration to final assembly and testing. Buyers benefit from consolidated sourcing networks where raw materials, electronic controls, and mechanical parts are sourced within 50km, reducing lead times to 20–35 days for standard orders. The presence of OEM and ODM-capable factories allows for flexible MOQs and product customization, particularly in knitting, food processing, and construction applications.

How to Choose Linking Machine Suppliers?

Procurement decisions should be guided by objective supplier evaluation criteria:

Technical Specialization

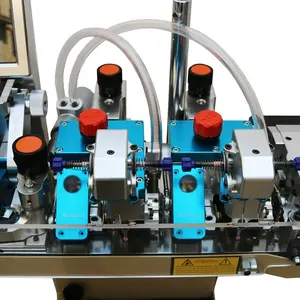

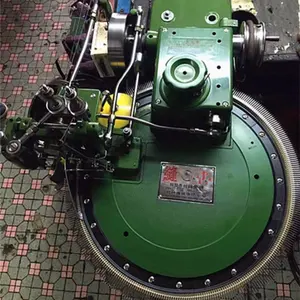

Identify suppliers aligned with your application: textile (socks, sweaters), food (sausage, hot dog linking), or industrial (chain-link fencing). Verify machine specifications such as drive type (servo vs. manual), stitching speed, needle configuration, and compatibility with target materials (e.g., cotton, nylon, stainless steel casings).

Production and Quality Verification

Prioritize suppliers demonstrating measurable operational performance:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate exceeding 20% as an indicator of customer satisfaction

- In-house R&D or engineering teams for customization support

Confirm quality control processes through verifiable metrics rather than self-reported claims.

Customization and Transaction Security

Assess flexibility in design modifications—color, size, voltage, software interface, or branding. Require documented compliance with international standards (CE, ISO) where applicable. Utilize secure payment terms such as escrow or milestone-based disbursements, especially for first-time engagements. Request product samples to evaluate build quality and functional reliability before bulk ordering.

What Are the Best Linking Machine Suppliers?

| Company Name | Specialization | Verified Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Hefei HD Machinery Co., Ltd. | Textile Linking Machines | Custom Manufacturer | 98% | ≤4h | 22% | US $1M+ | 1–10 sets |

| Zhengzhou Yize Machinery Co., Ltd. | Sock & Footwear Linking | Multispecialty Supplier | 98% | ≤2h | 30% | US $450K+ | 1 set |

| Zhengzhou Hento Machinery Co., Ltd. | Food Processing Linkers | Brand Holder | 100% | ≤1h | 20% | US $360K+ | 1 set |

| Shijiazhuang Tops Hardware Manufacturing Co., Ltd. | Chain-Link Fence Machines | Multispecialty Supplier | 100% | ≤2h | 100% | US $770K+ | 1 set |

| Guangzhou Chashimi Kitchen Equipment Co., Ltd. | Manual Sausage Tying | Multispecialty Supplier | 94% | ≤5h | <15% | US $160K+ | 2–10 pieces |

Performance Analysis

Shijiazhuang Tops demonstrates exceptional reliability with a 100% on-time delivery and reorder rate, indicating strong fulfillment consistency and customer retention, ideal for long-term procurement contracts. Zhengzhou Yize stands out in responsiveness (≤2h) and repeat business (30% reorder rate), making it suitable for buyers requiring agile communication. Hefei HD offers broad customization in textile machinery with high revenue volume, signaling market validation. For food industry applications, Zhengzhou Hento provides competitively priced automatic linkers with fast turnaround. Guangzhou Chashimi caters to low-volume buyers with piece-level MOQs, though lower reorder rates suggest room for service improvement.

FAQs

What types of linking machines are available from Chinese suppliers?

Suppliers offer specialized machines including sock toe-linking, sweater seam linking, automatic sausage linking, manual tying devices, and fully automated chain-link fence makers. Selection depends on material type, production speed, and automation level required.

What is the typical MOQ for linking machines?

MOQs range from 1 set for high-value automated models to 2–10 pieces for manual or compact units. Some suppliers allow single-unit sampling at premium pricing. Bulk orders often unlock unit cost reductions of 10–20%.

How long does production and shipping take?

Lead time averages 20–30 days for manufacturing, plus 15–30 days for sea freight depending on destination. Air shipping reduces transit time to 5–10 days but increases logistics costs by 200–300%. Confirm Incoterms (FOB, CIF) early in negotiation.

Can suppliers customize linking machines?

Yes, most suppliers support customization in voltage (110V/220V), control interface language, machine dimensions, color, branding (logo printing), and integration with existing production lines. Software-driven models may allow pattern programming for textile applications.

Are certifications provided for export compliance?

While not universally listed, reputable suppliers can provide CE marking upon request for European markets. Buyers should explicitly request test reports, electrical safety documentation, and material compliance (RoHS, REACH) during due diligence.