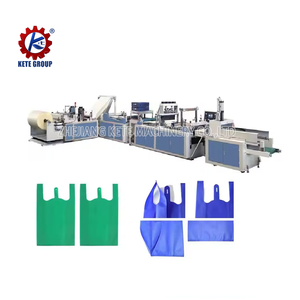

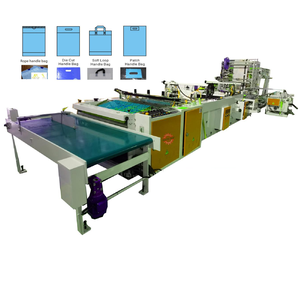

Loop Handle Making Machine

CN

CN

CN

CN

About loop handle making machine

Where to Find Loop Handle Making Machine Suppliers?

China remains the central hub for loop handle making machine manufacturing, with key production clusters concentrated in Zhejiang and Wenzhou regions. These industrial zones host vertically integrated supply chains specializing in automated bag fabrication equipment, supported by mature ecosystems of component suppliers, CNC workshops, and logistics networks. The proximity of raw material providers—particularly for non-woven polypropylene, PE films, and ultrasonic welding systems—enables localized production cycles and cost efficiencies.

Suppliers in these regions benefit from established export infrastructure, facilitating direct access to global markets. Facilities typically integrate R&D, machining, assembly, and testing under one roof, allowing lead times as short as 30–45 days for standard configurations. Buyers gain advantages in scalability, with some manufacturers reporting monthly outputs exceeding 50 units per model line. Cost structures are optimized through regional specialization: Zhejiang-based firms dominate high-speed automation systems, while Wenzhou producers focus on mid-range thermal sealing and hot-press attachment technologies.

How to Choose Loop Handle Making Machine Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Compliance

Verify adherence to international safety and quality benchmarks such as CE marking and ISO 9001 certification, especially for buyers targeting EU or North American markets. Confirm that machines meet electrical safety standards (e.g., IEC 60204) and include documentation for critical subsystems like servo drives, pneumatic controls, and ultrasonic welders. Machines designed for biodegradable or recyclable materials should support precise temperature control and tension regulation to prevent film degradation.

Production Infrastructure Assessment

Evaluate manufacturer capacity using objective indicators:

- Facility size supporting dedicated assembly lines (minimum 3,000m² recommended)

- In-house engineering teams capable of customizing speed, film width (up to 800mm), and handle attachment methods (thermal, ultrasonic, or mechanical crimping)

- Integration of IoT-enabled monitoring systems for real-time performance tracking

Cross-reference claimed capabilities with verified delivery records—suppliers maintaining ≥97% on-time fulfillment are more likely to sustain production consistency.

Customization and Transaction Security

Prioritize suppliers offering documented customization options including color coding, logo imprinting, variable bag dimensions, and compatibility with multiple substrate types (PP, HDPE, LDPE, non-woven fabrics). Ensure contracts include third-party inspection clauses before shipment. Utilize secure payment mechanisms that release funds only after destination verification. Pre-shipment testing should validate output accuracy, weld strength, and system stability over continuous operation (minimum 72-hour run test).

What Are the Best Loop Handle Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Key Features |

|---|---|---|---|---|---|---|---|

| Zhejiang Zhengxin Machinery Co., Ltd. | Zhejiang, CN | US $1.3M+ | 100% | ≤1h | 53% | $4,600–$85,000 | IoT integration, biodegradable film support, flexo printing compatibility |

| Zhejiang Chovyting Machinery Co., Ltd. | Zhejiang, CN | US $1.1M+ | 100% | ≤3h | 40% | $6,500–$62,000 | Ultrasonic welding, multi-film compatibility, compact design |

| Wenzhou Bosen Machinery Co., Ltd. | Wenzhou, CN | US $150K+ | 100% | ≤4h | 50% | $10,000–$15,000 | High-speed automation, thermal sealing, clothing packaging specialization |

| Zhejiang Zhengwei Machinery Co., Ltd. | Zhejiang, CN | Not disclosed | 100% | ≤8h | Not disclosed | $85,000–$280,500 | Luxury gift bag lines, smart threading, fully automatic lines |

| Wenzhou Zhongqi Machinery Co., Ltd. | Wenzhou, CN | US $200+ | 100% | ≤5h | <15% | $14,500–$30,000 | Multi-line hot sealing, vest bag production, blown film integration |

Performance Analysis

Zhejiang-based suppliers demonstrate superior technological breadth, with Zhengxin and Chovyting offering scalable solutions ranging from entry-level $4,600 models to advanced IoT-connected systems. Zhengxin stands out with a 53% reorder rate and sub-one-hour response time, indicating strong post-sale satisfaction and service agility. Bosen offers competitively priced machines focused on plastic and garment packaging applications, achieving a balanced 50% reorder rate. Zhengwei targets premium segments with high-cost integrated lines exceeding $280,000, suitable for luxury retail packaging. Wenzhou Zhongqi, despite lower online revenue visibility, provides versatile multi-function platforms but shows limited customer retention based on its <15% reorder rate. Buyers seeking automation depth should prioritize suppliers with proven experience in integrating loop handling, cutting, and sealing into single-stream operations.

FAQs

How to verify loop handle making machine supplier reliability?

Cross-check compliance certifications (CE, ISO) with issuing bodies and request factory audit reports. Analyze transaction history, focusing on consistent on-time delivery (target ≥98%) and response efficiency (ideally ≤4 hours). Review product listings for technical specificity—reliable suppliers provide detailed specs on motor power, cycle speed (bags/min), film thickness range (0.01–0.05mm), and energy consumption.

What is the typical lead time for standard and customized machines?

Standard models are typically delivered within 30–45 days after order confirmation. Customized systems involving unique film paths, dual-handle configurations, or integrated printing modules may require 60–90 days, depending on complexity. Expedited builds are occasionally available for an additional fee.

Do suppliers offer customization options?

Yes, most leading suppliers support modifications including handle length, bag width (up to 800mm), operating speed (40–200 bags/min), and material compatibility (PP, PE, non-woven). Advanced features like auto-punching, QR code labeling, and servo-driven feeding can be engineered upon request. Confirmation via 3D renderings or prototype videos is standard practice.

Can loop handle making machines process biodegradable materials?

Selected models—particularly those from Zhengxin and Chovyting—are configured for PLA, PBAT, and other compostable substrates. These require precision temperature control and corrosion-resistant rollers to maintain seal integrity without compromising film structure. Confirm machine specifications explicitly list biodegradable film compatibility before procurement.

What are common MOQ and pricing terms?

Most suppliers set a minimum order quantity of 1 set, with prices ranging from $4,600 for basic models to over $280,000 for fully automated production lines. Bulk purchases (≥5 sets) may qualify for discounts, training packages, or extended warranties. Payment terms usually involve 30% deposit, balance before shipment, with options for trade assurance or letter of credit.