Machine Building Systems Ltd

1/24

1/24

1/47

1/47

1/11

1/11

CN

CN

1/17

1/17

1/22

1/22

1/41

1/41

1/24

1/24

1/19

1/19

1/22

1/22

1/10

1/10

1/19

1/19

1/19

1/19

1/9

1/9

1/20

1/20

1/19

1/19

1/30

1/30

1/25

1/25

CN

CN

1/18

1/18

1/11

1/11

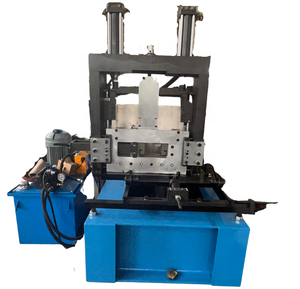

About machine building systems ltd

Where to Find Machine Building Systems Suppliers?

China remains the central hub for machine building systems manufacturing, with key industrial clusters in Jiangsu, Hebei, and Henan provinces driving innovation and export capacity. Wuxi in Jiangsu Province hosts advanced modular construction equipment producers leveraging proximity to Shanghai’s logistics network, enabling faster global shipment cycles. Cangzhou in Hebei benefits from concentrated roll forming machinery expertise and integrated steel processing zones, reducing raw material lead times by up to 25%. Zhengzhou-based manufacturers specialize in high-capacity automated lines for roofing and structural components, supported by regional government incentives for smart manufacturing upgrades.

These clusters offer vertically integrated production ecosystems where suppliers manage everything from PLC integration to final assembly in-house. This consolidation enables tighter quality control, shorter development timelines (typically 30–45 days for standard configurations), and cost advantages of 20–35% over Western-built equivalents. Buyers benefit from scalable solutions—from compact semi-automatic units for small enterprises to fully automated turnkey systems capable of 1,500+ kg/h output—supported by mature technical labor pools and component supply chains within 50 km radii.

How to Choose Machine Building Systems Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline indicator of consistent quality management. For international deployments, confirm CE marking compliance to meet EU safety, health, and environmental standards. Request documentation on PLC system validation (e.g., Siemens or Delta compatibility), motor efficiency ratings, and material traceability reports—especially for galvanized steel or pressure vessel-grade components.

Production Capability Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory footprint of 3,000m² to support dedicated production lines

- In-house engineering teams handling custom design, CAD drawing integration, and control system programming

- On-site CNC machining, welding, and hydraulic testing capabilities

Cross-reference these with on-time delivery performance (target ≥95%) and reorder rates to assess reliability and customer satisfaction.

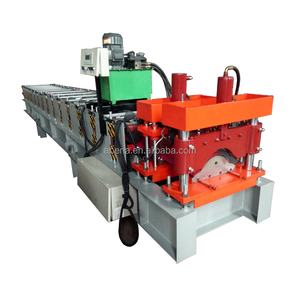

Customization & Quality Assurance

Confirm scope of customization including cross-sectional profile adjustment, material thickness range (typically 0.3–2.5mm), color coating options, and integration of alarm systems or dual-layer feeding platforms. Demand sample testing protocols—particularly for dimensional accuracy, cut precision, and long-term operational stability under continuous load. Prioritize suppliers offering pre-shipment inspection reports and third-party audit access.

Transaction Security

Utilize secure payment mechanisms such as escrow services that release funds only after equipment verification. Review online transaction history where available, focusing on dispute resolution records and post-sale service responsiveness. A response time under 2 hours indicates strong client support infrastructure.

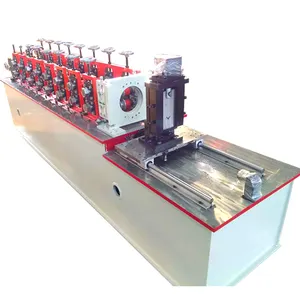

What Are the Best Machine Building Systems Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Value (USD) | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Sussman Machinery (wuxi) Co.,Ltd | Jiangsu, CN | Multispecialty Supplier | US $660,000+ | 100% | 100% | ≤1h | $17,500 | Width, motor, shape, thickness, PLC, packaging, graphic, holes |

| Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd. | Hebei, CN | Custom Manufacturer | US $1,100,000+ | 85% | 100% | ≤1h | $7,630 | Color, thickness, width, rollers, profile, gearbox, double-layer, hydraulic platform |

| Zhengzhou Howann Machinery Co., Ltd. | Henan, CN | Custom Manufacturer | US $460,000+ | 100% | 33% | ≤1h | $3,000 | Shape, oil pump, bearing, monitor, hydraulic layout, cutters, shaft design |

| Sussman Modular House (wuxi) Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $60,000+ | 100% | - | ≤2h | $34,000 | Material size, color, logo, packaging, label, graphic |

| Shandong Shengya Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | US $7,000+ | 100% | <15% | ≤6h | $2,600 | Molds, capacity, hydraulic system, brick shape, die cutting, rotary paving |

Performance Analysis

Sussman Machinery stands out with perfect on-time delivery and reorder rate alignment, indicating strong process consistency and customer retention. Cangzhou Forward leads in revenue volume (over US $1.1M) and offers highly configurable roll forming systems at competitive entry pricing starting from $7,630 per set. Zhengzhou Howann specializes in premium automated lines priced at $700,000 per unit, targeting large-scale construction material producers requiring high-standard turnkey installations.

Jiangsu-based suppliers demonstrate superior service responsiveness (≤1h average), while Hebei and Henan manufacturers provide broader customization depth in roller design and hydraulic integration. Despite lower reorder rates, Shandong Shengya serves niche markets with affordable block-making machines, ideal for startups or regional contractors. For mission-critical procurement, prioritize suppliers with documented R&D departments and multi-point QC checks throughout fabrication.

FAQs

How to verify machine building systems supplier reliability?

Cross-validate ISO/CE certifications with official registries. Request facility videos showing live production runs and CNC calibration processes. Analyze transaction patterns—including confirmed order volume and buyer feedback on mechanical durability and after-sales support—to assess operational maturity.

What is the typical lead time for customized systems?

Standard configurations ship within 30–45 days. Fully customized builds with integrated PLC controls and specialized tooling require 50–70 days, depending on design complexity and component availability. Expedited production may reduce timelines by 10–15% at additional cost.

Can suppliers accommodate low-volume orders?

Yes, most manufacturers accept single-set orders, though unit prices are higher. Economies of scale begin at 2–3 sets. MOQs vary: some suppliers require two sets for smaller machines (e.g., brick makers), while larger systems like trapezoidal roof formers typically have a one-set minimum.

Do suppliers provide technical drawings and prototypes?

Reputable manufacturers offer free CAD drawings based on client specifications and can produce functional prototypes within 3–4 weeks. Video demonstrations of test runs are commonly provided pre-shipment for validation.

What are common customization options in machine building systems?

Key adjustable parameters include material thickness (0.3–3.0mm), feeding width (up to 1,500mm), cross-sectional profiles (C/Z/U/purlin/tile), automation level (PLC brand selection), color coding, hydraulic pressure settings, and packaging configuration. Advanced options include dual-layer co-extrusion, laser guidance, and IoT-enabled monitoring systems.