Machine For Production

CN

CN

About machine for production

Where to Find Production Machine Suppliers?

China remains the global epicenter for production machine manufacturing, with key industrial hubs in Henan, Hebei, and Zhejiang provinces driving innovation and scale. Henan province hosts a dense cluster of food and paper processing machinery manufacturers, supported by integrated supply chains for stainless steel, automation components, and packaging systems. This regional specialization enables cost efficiencies of 20–35% compared to equivalent suppliers in Southeast Asia or Eastern Europe. Proximity to major logistics nodes like Zhengzhou and Shanghai facilitates rapid export fulfillment, with average shipping lead times of 15–25 days via sea freight.

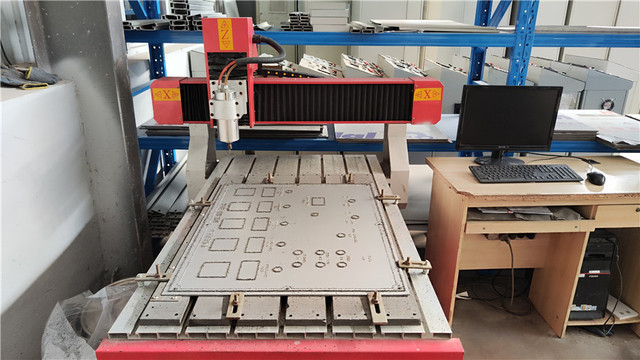

The sector benefits from vertically aligned ecosystems where raw material sourcing, CNC machining, assembly, and testing occur within compact geographic zones. This integration supports flexible production runs—from single-unit prototypes to high-volume orders exceeding 100 units monthly. Buyers gain access to mature technical networks featuring specialized engineers, third-party quality auditors, and after-sales service providers operating within 50 km of core manufacturing sites. These clusters are particularly strong in niche food processing equipment, including pasta, dumpling, tortilla, and snack-making machines, as well as paper product lines such as tissue and napkin manufacturing systems.

How to Choose Production Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical and Quality Compliance

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety—critical for market entry in Europe and North America. For food-grade machinery, ensure compliance with FDA or EU 1935/2004 regulations governing materials in contact with consumables. Request documentation on motor specifications (e.g., IP65-rated enclosures), stainless steel grades (preferably SUS304 or higher), and control system components (PLC brands like Siemens or Delta).

Production Capacity Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area of 2,000m² for sustained volume output

- In-house capabilities in CNC machining, welding, and automated assembly

- Dedicated R&D teams focused on process optimization and customization

Cross-reference claimed capacities with actual online revenue data and order fulfillment rates. Prioritize suppliers reporting consistent on-time delivery above 90%, indicating stable production planning and logistics coordination.

Customization and Transaction Security

Confirm scope and feasibility of customization—including voltage adaptation (110V/220V/380V), mold design, PLC interface language, and branding options (logo engraving, color finishes). Use secure payment mechanisms such as escrow services that release funds only upon equipment verification at destination. Insist on pre-shipment inspection reports and, where feasible, conduct virtual or on-site factory audits to validate claims about production processes and quality control protocols.

What Are the Best Production Machine Suppliers?

| Company Name | Specialization | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Product Lines |

|---|---|---|---|---|---|---|---|

| Xingtai Zhengruo Machinery Manufacturing Co., Ltd. | Pasta & Noodle Equipment | US $30,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, graphic | Spaghetti, macaroni, industrial pasta machines |

| Zhengzhou Top Machinery Co., Ltd. | Snack & Grain Processing | US $20,000+ | 100% | ≤2h | <15% | Limited (product-specific) | Tortilla lines, kibbeh formers, waffle cone makers |

| Hangzhou Jinghong Chuangda Machinery Co., Ltd. | Dumpling & Momo Automation | US $120,000+ | 91% | ≤2h | 20% | Extensive: shape, thickness, weight, tray count, mold size, dough mixer specs | Automatic momo, ravioli, steamed bun machines |

| Henan Qinbiao Industrial Development Co., Ltd. | High-Capacity Food Systems | US $50,000+ | 93% | ≤2h | <15% | Moderate (material, size) | Commercial pasta lines, automatic rollers, large-capacity processors |

| Henan Mayjoy Mechanical Equipment Co., Ltd. | Paper Product Machinery | US $260,000+ | 91% | ≤4h | 36% | Color, cutting length, core size, jumbo roll rewinding, sealing type, pulp source | A4 paper lines, toilet tissue machines, napkin printing systems |

Performance Analysis

Xingtai Zhengruo and Zhengzhou Top stand out for perfect on-time delivery records, making them suitable for time-sensitive procurement. Hangzhou Jinghong offers the broadest customization range, particularly valuable for buyers requiring precise food shaping and portion control. Henan Mayjoy leads in transaction volume, reflecting strong export experience and customer acquisition in the paper machinery segment. Reorder rates suggest varying post-sale satisfaction: while Mayjoy's 36% reorder rate indicates solid retention, others below 20% may require closer scrutiny of after-sales support. Suppliers with response times under 2 hours demonstrate operational responsiveness critical during technical negotiations and troubleshooting.

FAQs

What is the typical MOQ for production machines?

Most suppliers list a minimum order quantity of 1 unit, allowing buyers to test equipment performance before scaling. Bulk pricing typically applies at 5+ units, with negotiated discounts up to 10–15% depending on configuration complexity and container-load optimization.

How long does it take to fulfill an order?

Standard lead times range from 15 to 30 days after deposit confirmation. Custom-built systems, especially those involving unique molds or control panels, may require 35–45 days. Expedited production can reduce timelines by 5–7 days at additional cost.

Do suppliers offer machine customization?

Yes, most suppliers provide customization options ranging from basic (color, voltage) to advanced (mold geometry, feeding mechanism, PLC interface). Full engineering changes require detailed specifications and may involve prototype validation. Lead time extensions of 7–14 days are common for highly customized builds.

Can I request a sample or pre-shipment inspection?

Sample units are available for select models, typically at full price or with partial refunds upon bulk order placement. Pre-shipment inspections—either self-conducted, agent-assisted, or via third-party services like SGS—are standard practice and strongly recommended to verify functionality, build quality, and compliance with agreed specifications.

What are the shipping and import considerations?

Machinery shipments are commonly arranged under FOB or CIF terms. Sea freight is optimal for full-container loads due to lower cost per unit. Ensure compliance with destination country regulations regarding electrical safety, noise levels, and food contact materials. Import duties, customs clearance procedures, and inland transportation should be factored into total landed cost calculations.