Machine To Make Chocolate

Top sponsor listing

Top sponsor listing

About machine to make chocolate

Where to Find Chocolate Making Machine Suppliers?

China remains the central hub for chocolate making machine manufacturing, with key industrial clusters in Henan and Zhengzhou provinces driving production efficiency and export competitiveness. These regions host vertically integrated supply chains that streamline component sourcing—from servo motors and stainless steel fabrication to control systems—enabling rapid assembly and cost-effective scaling. Suppliers in this ecosystem benefit from proximity to raw material suppliers and logistics hubs, reducing lead times and transportation costs.

The concentration of specialized machinery manufacturers allows for both standardized equipment and fully customized production lines. Buyers can access compact tabletop units for small-scale chocolatiers or complete turnkey systems integrating grinding, tempering, molding, and enrobing processes. Average monthly output across active suppliers ranges from 50 to over 200 units, depending on automation level and order complexity. Localized manufacturing reduces production costs by 20–35% compared to European or North American equivalents, while maintaining compatibility with international food safety standards.

How to Choose Chocolate Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical capability, operational performance, and transactional reliability:

Technical & Food Safety Compliance

Verify adherence to ISO 9001 quality management systems as a baseline. For export to regulated markets, ensure CE marking and compliance with food-grade material standards (e.g., FDA-approved stainless steel contact surfaces). Request documentation for temperature control accuracy, motor efficiency ratings, and hygiene design—particularly for machines handling viscous chocolate paste or cocoa butter.

Production Capacity Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 2,000m² for sustained volume output

- In-house engineering teams capable of customizing capacity, mold designs, and servo-driven controls

- Integration of core processing stages: grinding, conching, tempering, depositing, cooling, and demolding

Cross-reference listed product range with actual machine diversity—suppliers offering full-line solutions typically demonstrate stronger technical integration.

Transaction Reliability Indicators

Prioritize suppliers with documented on-time delivery rates above 95% and reorder rates exceeding 15%, indicating customer retention. Response times under 4 hours suggest dedicated sales support. Use available revenue estimates (where disclosed) as proxies for market presence—suppliers reporting over US $200,000 in online revenue generally maintain consistent operations and inventory turnover.

What Are the Best Chocolate Making Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Skywin Foodstuff Machinery Co., Ltd. | Biscuit making machine (1901), Snack Machines (225) | 100% | 62% | ≤4h | $520,000+ | Color, mold, packaging, capacity, servo motor, label | $179–$10,000+ |

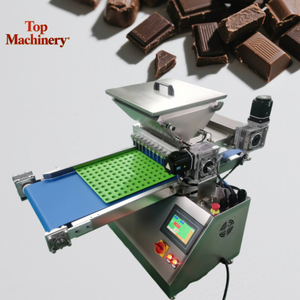

| Zhengzhou Top Machinery Co., Ltd. | Other Snack Machines (104), Grain Product Machines (83) | 100% | 15% | ≤2h | $20,000+ | Mold type, tank size, hopper configuration | $328–$4,399 |

| Youdo Machinery Inc | Grain Product Machines (503), Snack Machines (293) | - | - | ≤2h | - | Capacity, ball mill size, depositing system | $340–$10,000 |

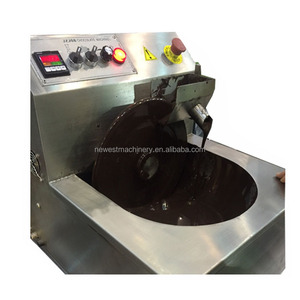

| Jiaozuo Newest Machinery Co., Ltd. | Other Snack Machines (1286), Fruit & Vegetable Machines (519) | 98% | <15% | ≤3h | $200,000+ | Tank count, motor power, user interface | $179–$3,400 |

| Henan Banglan Machinery Co., Ltd. | Conveyor systems, cocoa processing lines | 92% | <15% | ≤2h | $40,000+ | Belt type, screw conveyors, compressor integration | $1,350–$23,000 |

Performance Analysis

Skywin Foodstuff Machinery stands out with the highest reorder rate (62%) and substantial online revenue ($520,000+), suggesting strong customer satisfaction and repeat business—likely driven by extensive customization options and a broad product portfolio. Despite limited data transparency, Youdo Machinery offers high-end models up to $10,000, indicating specialization in commercial-grade equipment. Jiaozuo Newest and Skywin achieve near-perfect on-time delivery (98–100%), critical for time-sensitive procurement. Zhengzhou Top leads in responsiveness (≤2h) and maintains perfect delivery performance despite lower reorder frequency. Henan Banglan’s $23,000 flagship model reflects capability in large-scale, automated installations, suitable for industrial chocolate producers.

FAQs

How to verify chocolate making machine supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request proof of food-grade material usage (e.g., 304 stainless steel) and electrical safety testing. Analyze transaction history indicators such as on-time delivery rates, response speed, and verifiable customer reviews focusing on post-sale technical support.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set, accommodating sample trials and small businesses. Standard lead times range from 15 to 30 days after order confirmation, depending on customization level. Fully automated lines may require 45–60 days for assembly and testing.

Can suppliers customize chocolate machine configurations?

Yes, leading suppliers offer modifications in tank capacity (5L–100L), mold design, conveyor dimensions, motor type (servo vs. AC), and control panel language. Custom branding, voltage adjustment (110V/220V/380V), and integration with existing production lines are commonly supported upon request.

Do manufacturers provide samples or trial units?

Some suppliers offer functional demonstration units at full price, which may be credited toward bulk orders. True free samples are rare due to equipment size and cost; however, video demonstrations and remote operation tests are frequently provided for validation.

What are common packaging and export considerations?

Machines are typically shipped in wooden crates with moisture protection and shock-absorbing materials. Confirm FOB or CIF shipping terms, and ensure compliance with destination country regulations regarding electrical equipment and food processing machinery. Most suppliers partner with freight forwarders experienced in handling heavy industrial exports.