Make Your Own Semiconductor

About make your own semiconductor

Where to Find Semiconductor Component Suppliers?

Global semiconductor component manufacturing is anchored in specialized industrial hubs across China, with key clusters in Dongguan, Shenzhen, and Yixing driving innovation and scale. These regions host vertically integrated facilities that combine material processing, precision engineering, and electronics assembly under one ecosystem. Shenzhen leads in integrated circuit (IC) and discrete semiconductor production, supported by a dense network of electronic component distributors and testing labs. Dongguan specializes in high-precision CNC-machined parts for semiconductor equipment, leveraging proximity to Guangzhou’s logistics infrastructure for rapid export fulfillment. Yixing focuses on ceramic substrates and insulating components critical for power module packaging, utilizing locally sourced high-purity alumina materials.

Suppliers in these zones benefit from mature supply chains that reduce lead times by 20–30% compared to non-specialized regions. Buyers gain access to agile production networks capable of fulfilling both low-volume custom orders and scalable batch manufacturing. Typical advantages include localized sourcing of raw materials (e.g., 995-grade alumina ceramics, silicon wafers), in-house tooling and prototyping capabilities, and compliance-ready quality management systems. Lead times for standard components range from 15 to 30 days, with customization cycles extending to 45 days depending on complexity.

How to Choose Semiconductor Component Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Technical Compliance and Certifications

Verify adherence to international quality standards such as ISO 9001 for quality management and RoHS for hazardous substance compliance. For ICs and active components, ensure traceability through batch numbering and testing reports (e.g., electrical performance, thermal resistance). Suppliers handling medical or aerospace-grade parts may also comply with AS9100 or IATF 16949, indicating advanced process controls.

Production Capability Evaluation

Assess core manufacturing competencies through the following criteria:

- In-house CNC machining, grinding, or wafer dicing capabilities for dimensional accuracy

- Material expertise in semiconductor-grade ceramics (Al₂O₃, AlN), silicon substrates, or metal frames

- Customization capacity for size, doping type (N/P), surface finish, and packaging configurations

Cross-reference supplier claims with response time metrics (target ≤3 hours) and on-time delivery rates (ideal ≥97%) to validate operational efficiency.

Transaction and Quality Assurance

Prioritize suppliers offering sample validation before mass production. Require material certification and test data for critical parameters such as dielectric strength, thermal conductivity, or sheet resistance. Use secure transaction models where payment is contingent upon inspection at destination. Confirm export experience via documented shipment histories and compliance with international shipping regulations for electronic components.

What Are the Best Semiconductor Component Suppliers?

| Company Name | Specialization | Main Materials | Processing Techniques | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Yixing K.F Ceramic Manufacturing Co., Ltd. | Ceramic substrates & insulators | 995-Alumina Ceramic | Pressing, sintering, grinding | - | ≤4h | US $700+ | <15% | Size, color, logo, packaging |

| Yokan Precision Technology (Dongguan) Co., Ltd. | Precision CNC parts for semiconductor equipment | Metal, plastic | CNC machining, milling, turning | 100% | ≤17h | - | - | Material, size, logo, packaging |

| Shenzhen Jeking Electronic Corp. | Discrete semiconductors, ICs, modules | Silicon, SMD components | Surface mount, packaging, testing | 100% | ≤3h | US $350,000+ | 38% | PCB material, transistors, relays, refurbished units, USB type |

| Dongguan Shichuang Hardware Technology Co., Ltd. | Metal fabrication for semiconductor machinery | Aluminum, stainless steel | CNC machining, laser cutting, welding | 100% | ≤2h | US $40,000+ | 15% | Color, size, logo, packaging |

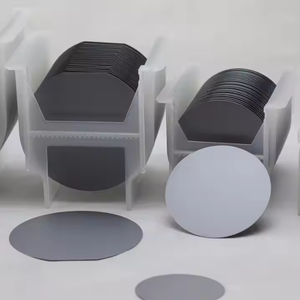

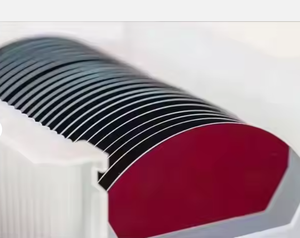

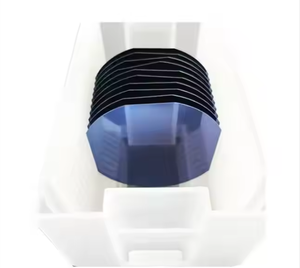

| Wonik Semicon Co., Ltd. | Silicon wafers, N/P-type substrates | Silicon, quartz | Wafer slicing, polishing, coating | 100% | ≤3h | US $2,000+ | <15% | Wafer diameter (4–8 inch), doping type, thickness |

Performance Analysis

Shenzhen Jeking Electronic stands out with the highest reorder rate (38%) and substantial online revenue, indicating strong market trust in its semiconductor ICs and module offerings. Wonik Semicon and Dongguan Shichuang demonstrate superior responsiveness (≤3h and ≤2h, respectively), making them suitable for time-sensitive procurement. Yokan Precision and Shichuang offer broad CNC machining capabilities essential for semiconductor equipment spares, while Yixing K.F Ceramic provides niche expertise in high-alumina ceramic components used in power electronics packaging. Suppliers with verified customization options—including wafer specifications, PCB integration, and branding—offer greater flexibility for R&D and pilot production runs.

FAQs

How to verify semiconductor supplier reliability?

Validate certifications through official registries and request product-specific test reports (e.g., IV curves for diodes, thermal cycling data). Conduct virtual audits via facility videos or live calls to assess production lines and quality control stations. Analyze transaction history, focusing on dispute resolution patterns and customer feedback related to consistency and technical support.

What is the typical sampling timeline for semiconductor components?

Standard samples are produced within 7–14 days. Custom silicon wafers or ceramic substrates require 15–25 days due to processing steps like sintering or doping. Add 5–10 days for international air shipping. Complex IC packaging or multi-layer ceramic substrates may extend sampling to 35 days.

Do suppliers support global shipping?

Yes, most established suppliers manage international logistics via air or sea freight. Confirm Incoterms (FOB, CIF) and ensure compliance with import regulations for electronic goods in the destination country. Semiconductor-grade materials may require special handling documentation.

Are free samples available?

Sample policies vary. Low-cost components (e.g., resistors, basic wafers) may be provided free for qualified buyers placing future bulk orders. For high-value items like ICs or machined ceramic blocks, expect to pay 30–70% of unit cost, often credited toward first orders exceeding MOQ thresholds.

How to initiate a customization request?

Submit detailed specifications including material grade (e.g., 995-alumina, N-type silicon), dimensions, tolerance levels (±0.01mm typical), surface finish, and functional requirements. Reputable suppliers respond with feasibility assessments within 48 hours and provide prototypes within 3–5 weeks for validation.