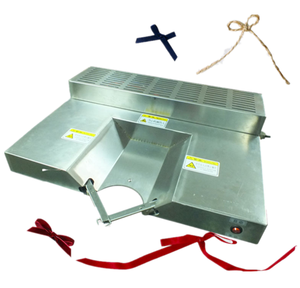

Making A Bow With Bow Maker

1/16

1/16

1/39

1/39

1/9

1/9

1/12

1/12

1/14

1/14

1/20

1/20

1/16

1/16

1/22

1/22

About making a bow with bow maker

Where to Find Bow Making Machine Suppliers?

China remains the central hub for industrial bow making equipment production, with key manufacturing clusters in Guangdong, Zhejiang, and Henan provinces. Shenzhen and Ningbo serve as primary centers for automated ribbon processing machinery, hosting vertically integrated facilities that combine R&D, precision engineering, and export logistics. These regions benefit from mature supply chains for servo motors, cutting blades, and control systems, reducing component lead times by 25–30% compared to non-specialized regions.

The concentration of technical expertise enables rapid prototyping and scalable production. Suppliers in these zones typically operate multi-disciplinary workshops equipped for CNC machining, sheet metal fabrication, and electrical integration, supporting both standard and custom configurations. Buyers gain access to agile manufacturing ecosystems where material sourcing, assembly, and quality testing occur within tightly coordinated networks, facilitating average production lead times of 20–35 days for machine orders. Cost efficiencies range from 18–30% over Western manufacturers due to localized production and optimized labor allocation.

How to Choose Bow Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. For suppliers targeting EU or North American markets, CE marking is essential for regulatory compliance. Request documentation on motor efficiency ratings, blade durability tests, and electrical safety certifications (e.g., IEC 60204). Evaluate product listings for consistent technical specifications—precision in ribbon width tolerance (±0.5mm), programmable cycle controls, and adjustable tension systems indicate higher engineering rigor.

Production Capability Assessment

Assess infrastructure maturity through verifiable metrics:

- Facilities exceeding 2,000m² suggest capacity for batch production

- In-house design teams enable customization of bow shape, size, and ribbon feed mechanism

- Integration of PLC controls and servo-driven systems reflects advanced automation capability

Cross-reference online revenue data and reorder rates (>25% preferred) as indicators of market validation and reliability.

Procurement Safeguards

Utilize secure payment methods with escrow functionality to mitigate risk. Prioritize suppliers with documented after-sales support, including remote troubleshooting and spare parts availability. Conduct sample testing to validate output consistency—benchmark against required bow dimensions, knot tightness, and ribbon integrity after high-volume runs (1,000+ units).

What Are the Best Bow Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Ningbo Credit Ocean Machinery & Electron Co., Ltd. | Zhejiang, CN | US $510,000+ | 97% | ≤6h | 35% | 1 set | $540–14,000 | Yes |

| Huizhou Yiyuan Machinery Co., Ltd. | Guangdong, CN | US $240,000+ | 91% | ≤1h | 19% | 1 set | $600–700 | No |

| Henan Kellen Machinery Equipment Co., Ltd. | Henan, CN | US $490,000+ | 95% | ≤3h | 15% | 1 set | $490–780 | No |

| Shenzhen Guangyunda Technology Co., Ltd. | Guangdong, CN | US $4,000+ | 100% | ≤6h | 18% | 1–2 sets | $4,650–9,699 | No |

| Puyang Hechang Handicraft Product Co., Ltd. | Henan, CN | US $130,000+ | 93% | ≤4h | 27% | 300 pieces | $1.70/unit | Yes |

Performance Analysis

Ningbo Credit Ocean leads in scalability and customization, offering semi-automatic to fully automatic models with broad ribbon width and material compatibility. Its 35% reorder rate reflects strong customer retention, supported by flexible configuration options. Huizhou Yiyuan and Henan Kellen provide cost-effective entry-level machines priced between $490–700, suitable for small-scale producers, though limited customization and lower reorder rates suggest narrower service focus. Shenzhen Guangyunda specializes in high-capacity systems but at significantly higher price points, indicating a niche in premium automation. Puyang Hechang stands out as a manual tool supplier, catering to craft-based operations with low MOQs and design flexibility, ideal for seasonal or artisanal production.

FAQs

How to verify bow making machine supplier reliability?

Validate certifications (ISO, CE) through independent databases. Request factory audit reports or video walkthroughs confirming production lines and quality control stations. Analyze transaction history, focusing on on-time delivery consistency and dispute resolution performance.

What is the typical sampling timeline?

Standard machine samples require 10–20 days for production. Custom-configured units may take 25–40 days depending on complexity. Shipping via air freight adds 5–10 days internationally. Manual tools like wooden bow formers ship within 7 days.

Can suppliers ship globally?

Yes, most established manufacturers offer FOB, CIF, and DDP shipping terms. Confirm inclusion of export packaging, customs documentation, and compliance with destination electrical standards (voltage, plug type) before order placement.

Do suppliers offer free samples?

Free samples are rare for machinery. Buyers typically pay full or partial sample costs, which may be credited toward bulk orders (e.g., 1+ unit contracts). Low-cost items like manual bow makers may have waived fees for trial purchases.

How to initiate customization requests?

Submit detailed requirements: desired bow dimensions, ribbon width (1–5cm typical), material type (satin, organza, wired ribbon), output speed (units/hour), and power supply (110V/220V). Suppliers with in-house engineering teams can provide CAD drawings and functional prototypes within 1–2 weeks.