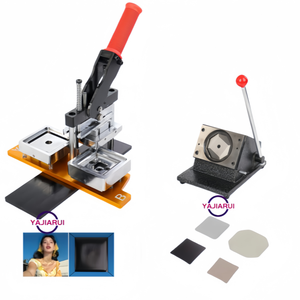

Manual Button Machine

About manual button machine

Where to Find Manual Button Machine Suppliers?

China remains the central hub for manual button machine manufacturing, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains that streamline component sourcing—such as dies, molds, and metal stamping parts—enabling rapid assembly and consistent output. Yiwu and Dongguan have emerged as specialized centers for small-scale badge and promotional product machinery, benefiting from proximity to raw material suppliers and packaging facilities.

The industrial ecosystem supports both high-volume OEM orders and low-MOQ customized configurations. Factories typically operate semi-automated assembly lines capable of producing 500–2,000 units per month, depending on model complexity. This infrastructure allows suppliers to maintain competitive pricing while accommodating flexible order sizes. Buyers benefit from consolidated logistics networks, particularly in coastal hubs, where export processing times average 15–25 days after order confirmation.

How to Choose Manual Button Machine Suppliers?

Evaluating suppliers requires a structured assessment of technical capability, transaction reliability, and customization support:

Production and Engineering Capacity

Assess whether suppliers possess in-house tooling and die-making capabilities, which are critical for maintaining press alignment accuracy and long-term durability. Machines must consistently handle materials ranging from 0.2–0.8mm steel or aluminum sheets without deformation. Prioritize manufacturers with documented quality control processes, including load testing and cycle endurance validation.

Quality and Compliance Verification

While formal certifications such as ISO 9001 or CE are not universally present among smaller exporters, evidence of standardized production practices should be verified. Request test reports or video demonstrations showing completed button formation under real operating conditions. For commercial buyers in regulated markets, confirm compatibility with safety standards for hand-operated mechanical devices.

Transaction Reliability Indicators

Analyze supplier performance metrics:

- On-time delivery rates exceeding 90% indicate reliable production planning

- Response times under 3 hours reflect active order management

- Reorder rates above 15% suggest customer satisfaction with product quality and service consistency

- Online transaction volume (e.g., >US $100,000 annually) correlates with operational scale and inventory stability

What Are the Best Manual Button Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | Button Making Machines (944) | US $130,000+ | 100% | ≤3h | 17% | N/A |

| Dongguan Ruiyee Machinery Co., Ltd. | Guangdong, CN | Button Making Machines (N/A) | US $180,000+ | 100% | ≤2h | 15% | Color, material, size, logo, packaging, label, graphic |

| Henan Jinfuda Trading Co., Ltd. | Henan, CN | Button Making Machines (N/A) | US $570,000+ | 98% | ≤3h | <15% | Color, material, size, logo, packaging, label, graphic |

| Jiangsu Enters Industrial Co., Ltd. | Jiangsu, CN | Button Making Machines (225) | US $120,000+ | 91% | ≤4h | <15% | N/A |

| Yiwu Chuxin Technology Co., Ltd. | Zhejiang, CN | Button Making Machines (106) | US $10,000+ | 86% | ≤2h | 20% | N/A |

Performance Analysis

Yancheng Stik Pro stands out with a 100% on-time delivery rate and extensive product catalog, indicating robust production management. Dongguan Ruiyee and Henan Jinfuda offer strong customization capabilities across material, size, and branding parameters—critical for buyers targeting niche markets or private-label distribution. Henan Jinfuda leads in annual online revenue, suggesting higher export volume and market penetration. Yiwu Chuxin, despite lower revenue, demonstrates the highest reorder rate (20%), reflecting strong end-user satisfaction relative to its scale. Buyers requiring fast communication should prioritize suppliers with response times under 2 hours, such as Dongguan Ruiyee and Yiwu Chuxin.

FAQs

What is the typical MOQ for manual button machines?

Most suppliers list a minimum order quantity of 1 piece/set, allowing for sample testing or small business procurement. Bulk pricing typically applies at 10+ units, with discounts varying by model and customization level.

What are common customization options?

Available customizations include machine color, press size (ranging from 25mm to 90mm), material finish, branded logos, and packaging design. Suppliers like Dongguan Ruiyee and Henan Jinfuda explicitly support full graphic and labeling modifications for OEM clients.

What is the average lead time after order placement?

Standard orders are processed within 7–15 days. Customized units may require 15–25 days, depending on tooling adjustments. Air freight adds 5–10 days for international delivery, while sea shipping ranges from 20–35 days based on destination port.

Do suppliers provide technical documentation or operation manuals?

Yes, most suppliers include digital user guides in English. High-volume buyers can request instructional videos or troubleshooting documents. Some manufacturers offer remote setup support via video call for first-time operators.

How to verify machine compatibility with button components?

Confirm die dimensions (e.g., 50x50mm, 80x53mm) match your intended button blanks and backings. Request sample output using your specified materials to validate crimp quality and alignment precision before scaling procurement.