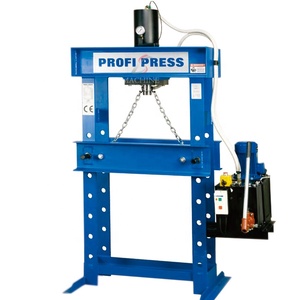

Manual Press Producer

1/3

1/3

0

0

0

0

1/23

1/23

1/3

1/3

CN

CN

1/16

1/16

1/15

1/15

1/3

1/3

1/3

1/3

1/20

1/20

1/3

1/3

1/3

1/3

0

0

1/19

1/19

1/24

1/24

1/19

1/19

1/18

1/18

1/24

1/24

1/3

1/3

About manual press producer

Where to Find Manual Press Producers?

China remains the central hub for manual press manufacturing, with key industrial clusters in Guangdong, Shandong, and Zhejiang provinces driving production efficiency and export capacity. Dongguan and Jiangsu-based suppliers specialize in hydraulic and precision machining systems, supported by vertically integrated supply chains that reduce component lead times by up to 30%. These regions host specialized machinery zones where casting, CNC processing, and final assembly occur within tightly coordinated networks, enabling faster turnaround and cost-effective scaling.

The concentration of technical labor and mature logistics infrastructure allows suppliers to maintain competitive pricing while supporting both standardized and engineered-to-order configurations. Buyers benefit from localized ecosystems featuring certified material suppliers, third-party quality inspectors, and freight forwarders operating within proximity, facilitating end-to-end oversight. Typical advantages include MOQs as low as one set, lead times ranging from 15–30 days for stock models, and customization capabilities across tonnage (5T–100T), frame design, and control interfaces.

How to Choose Manual Press Suppliers?

Effective supplier selection requires structured evaluation based on verifiable operational metrics:

Production & Engineering Capability

Confirm access to in-house fabrication resources including CNC machining centers, welding bays, and hydraulic system integration. Suppliers with dedicated R&D teams are better equipped to support custom modifications such as dual-cylinder synchronization or compact frame designs. Prioritize companies listing more than 100 units of hydraulic presses or related machinery, indicating established production lines and consistent output capacity.

Quality Assurance Protocols

While formal certifications (ISO 9001, CE) are not universally declared in available data, performance indicators offer alternative validation:

- On-time delivery rates ≥96% correlate with reliable internal scheduling and inventory management

- Response times ≤2 hours suggest active customer service systems and organizational responsiveness

- Reorder rates above 25% reflect post-delivery satisfaction and product reliability

Request test reports for critical parameters such as maximum load tolerance, structural deflection under pressure, and weld integrity. For applications requiring regulatory compliance, verify CE marking through documentation rather than product claims.

Transaction Risk Mitigation

Utilize secure payment methods tied to milestone verification, particularly for first-time engagements. Insist on pre-shipment inspections either via third-party agencies or remote video audits. Evaluate customization transparency—suppliers offering options for color, logo imprinting, packaging, and material substitution typically have greater process flexibility and client-focused workflows.

What Are the Best Manual Press Producers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Dongguan Jianlong Hydraulic Machinery Co., Ltd. | Guangdong, CN | Hydraulic Presses (1,529) | 100% | ≤1h | - | - | Not specified |

| Shandong Wellde CNC Machine Tool Co., Ltd | Shandong, CN | Hydraulic Presses (143) | 80% | ≤3h | <15% | US $40,000+ | Not specified |

| Hangzhou Leo Filter Press Co., Ltd. | Zhejiang, CN | Filter Press Equipment (216) | 100% | ≤3h | - | - | Not specified |

| Jiangsu Yishou Machinery Technology Co., Ltd. | Jiangsu, CN | Not specified | 100% | ≤3h | <15% | US $10,000+ | Color, material, size, logo, packaging, label, graphic |

| Qingdao Zhongji Furun Machinery Equipment Manufacturing Co., Ltd. | Shandong, CN | Not specified | 96% | ≤2h | 25% | US $150,000+ | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Dongguan Jianlong stands out with extensive product listings in hydraulic presses (1,529), a 100% on-time delivery record, and sub-one-hour response times—indicative of robust operational systems. Hangzhou Leo focuses specifically on filter-type manual presses, serving niche industrial filtration markets with consistent fulfillment performance. Qingdao Zhongji Furun combines strong reorder activity (25%) with high online revenue and broad customization capabilities, suggesting effective client retention and market adaptability. In contrast, Shandong Wellde, despite diversified machine tool offerings, shows lower delivery reliability (80%), which may impact time-sensitive procurement plans.

FAQs

What is the typical price range for manual press machines?

Prices vary significantly based on tonnage and configuration, ranging from $68 for small benchtop units to over $99,000 for heavy-duty automated systems. Standard manual hydraulic presses (30–50T) typically fall between $300 and $700 per unit at MOQ 1 set.

Do manual press suppliers offer customization?

Yes, several suppliers explicitly list customization options including frame size, load capacity, paint color, branding elements, and packaging specifications. Companies like Jiangsu Yishou and Qingdao Zhongji Furun provide multi-point configurability, enabling buyers to align equipment with brand or operational requirements.

What are common minimum order quantities?

Most suppliers allow orders starting at 1 set, making them accessible for prototyping, testing, or low-volume deployment. Bulk pricing typically applies from 5 sets onward, with discounts varying by model complexity and production load.

How long does it take to receive a manual press after ordering?

Lead times generally range from 15 to 30 days for standard models. Custom-engineered units may require an additional 10–20 days depending on design approval cycles and component availability. Air freight reduces shipping duration to 5–10 days internationally.

Are samples available before bulk purchase?

Sample availability depends on supplier policy. Some manufacturers offer single-unit sales that function effectively as test units. Buyers should expect to pay full unit cost initially, though partial reimbursement may apply upon placing larger follow-up orders.