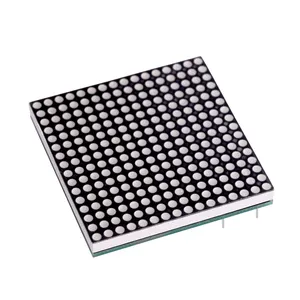

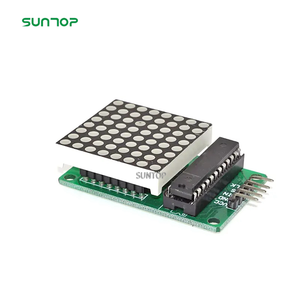

Matrix Codes

0

0

1/15

1/15

1/27

1/27

1/12

1/12

1/3

1/3

1/12

1/12

1/3

1/3

1/2

1/2

1/10

1/10

1/3

1/3

1/3

1/3

0

0

1/17

1/17

1/3

1/3

0

0

1/1

1/1

1/3

1/3

About matrix codes

Where to Find Matrix Codes Suppliers?

Global production of matrix codes—primarily referring to 2D data matrix symbols used in industrial marking, traceability, and product identification—is concentrated in manufacturing hubs with advanced laser etching, chemical etching, and direct part marking (DPM) capabilities. While physical "matrix codes" are not standalone products but rather encoded markings, the suppliers providing marking systems, verification equipment, and integrated coding solutions are predominantly based in China, Germany, and the United States. Within China, Guangdong and Jiangsu provinces host specialized clusters integrating precision engineering and automation technologies for high-volume industrial coding applications.

These regions support vertically integrated supply chains capable of delivering both hardware (e.g., fiber laser markers, thermal transfer coders) and software-driven code generation systems. Proximity to electronics, automotive, and medical device manufacturers enables rapid deployment of compliant, high-contrast matrix codes meeting ISO/IEC 16022 standards. Buyers benefit from localized technical support, scalable output, and compatibility with global serialization requirements such as FDA UDI, EU MDR, and IPC-1788. Lead times for standard marking systems typically range from 20–40 days, with cost advantages of 25–35% compared to Western-built equivalents due to optimized component sourcing and labor efficiency.

How to Choose Matrix Codes Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and compliance dimensions:

Technical Compliance

Ensure suppliers adhere to ISO/IEC 16022 for data matrix symbol structure and grading protocols per ISO/IEC TR 29158 (AIM DPM-1-2006). For regulated industries (medical, aerospace, automotive), demand documentation of code readability under variable lighting and surface conditions. Verification systems must provide grade reports (A–F scale) with contrast, modulation, and cell accuracy metrics.

Production Capability Audits

Assess supplier infrastructure for sustained quality in high-throughput environments:

- Minimum integration of automated vision inspection systems for real-time code validation

- In-house development of encoding algorithms and compatibility with ERP/MES platforms

- Proven experience with substrate-specific marking techniques (laser on metal, inkjet on plastic, electrochemical etching on surgical tools)

Validate performance through sample testing under actual operating conditions, including resistance to abrasion, corrosion, and sterilization cycles.

Transaction Safeguards

Require documented quality management system certification (ISO 9001:2015) and, where applicable, ISO 13485 for medical device traceability. Utilize third-party inspection services for pre-shipment audits when procuring turnkey marking lines. Confirm data security protocols for cloud-based code generation systems, particularly when handling serialized identifiers subject to anti-counterfeiting regulations.

What Are the Best Matrix Codes Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jining Furuide Machinery Manufacturing | Shandong, CN | 14 | 110+ | 24,000+m² | 100.0% | ≤2h | 4.8/5.0 | 33% |

| Henan Zlin Heavy Industry Group | Henan, CN | 4 | 20+ | 410+m² | 100.0% | ≤2h | 5.0/5.0 | 66% |

| Henan Guangzhida Industrial | Henan, CN | 3 | 30+ | 320+m² | 100.0% | ≤1h | 4.9/5.0 | 15% |

| Zhengzhou Zhongheng Machinery Equipment | Henan, CN | 3 | 60+ | 5,100+m² | 98.9% | ≤2h | 4.9/5.0 | 26% |

| Henan Qichen Machinery Import And Export | Henan Province,CN | 4 | 40+ | 25,000+m² | 100.0% | ≤1h | 4.9/5.0 | 29% |

Performance Analysis

Despite not being traditional producers of data matrix symbols, these machinery suppliers offer integrated marking solutions suitable for industrial serialization. Jining Furuide demonstrates strong scalability with a 24,000m² facility and perfect delivery record, ideal for large-scale automation projects. Henan Zlin stands out in customer retention (66% reorder rate), indicating high satisfaction with responsiveness and service follow-up. All listed suppliers maintain sub-2-hour average response times, with Henan-based firms leading in communication agility. Prioritize those with verified experience in DPM applications and laser coding integration, especially for sectors requiring permanent, machine-readable identifiers on components exposed to harsh environments.

FAQs

How to verify matrix codes supplier reliability?

Validate compliance with ISO/IEC 16022 and ISO/IEC TR 29158 through independent grading reports. Request case studies demonstrating successful implementation in your target industry. Audit supplier processes for consistency in mark placement, decode success rates, and integration with factory automation systems.

What is the average sampling timeline?

Prototype marking samples can be produced within 7–14 days depending on substrate and method. Full system trials with verification feedback require an additional 10–15 days. Air freight adds 5–9 days for international delivery.

Can suppliers ship coding systems worldwide?

Yes, established suppliers manage global logistics for marking equipment. Confirm Incoterms (FOB, CIF), customs classification under HS Code 8479.89, and voltage compatibility for electrical systems. Sea freight is recommended for multi-unit orders to reduce per-unit shipping costs.

Do manufacturers provide free samples?

Sample policies vary. Most suppliers offer complimentary test markings using client-provided materials or standard substrates. For full demonstration units, expect partial cost recovery unless tied to a confirmed order pipeline.

How to initiate customization requests?

Submit detailed requirements including material type, surface finish, code size (minimum 2x2mm up to 30x30mm), reading distance, and scanner compatibility. Reputable suppliers respond with feasibility assessments, proposed marking methods, and mock-up simulations within 72 hours.