Mazak Cnc Lathes

1/19

1/19

1/24

1/24

1/9

1/9

1/11

1/11

1/9

1/9

CN

CN

1/18

1/18

1/4

1/4

1/15

1/15

1/20

1/20

1/23

1/23

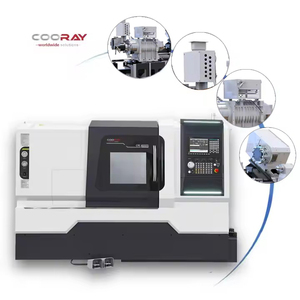

About mazak cnc lathes

Where to Find Mazak CNC Lathes Suppliers?

China serves as a central hub for suppliers offering CNC lathes compatible with or modeled after Mazak designs, with key manufacturing clusters located in Shandong and Guangdong provinces. Shandong, particularly the Jinan and Zaozhuang regions, hosts specialized CNC equipment manufacturers that benefit from proximity to steel processing centers and mature mechanical engineering ecosystems. This integration reduces component lead times by 20–25% compared to isolated production bases. Guangdong-based suppliers leverage advanced electronics manufacturing infrastructure, enabling tighter integration of Fanuc, Siemens, and Mitsubishi control systems commonly associated with Mazak machines.

These industrial zones support vertically integrated production, encompassing casting, precision machining, assembly, and final testing within consolidated facilities. Suppliers in these regions typically operate under lean manufacturing principles, maintaining average delivery cycles of 30–45 days for standard configurations. Buyers gain access to scalable production capacity, localized supply chains for linear guides, ball screws, and spindles, and cost advantages—evidenced by entry-level models starting below $8,000 and high-spec units priced between $60,000–$90,000. The concentration of technical labor and export-oriented logistics networks further enhances reliability for international procurement.

How to Choose Mazak CNC Lathe Suppliers?

Effective supplier selection requires structured evaluation across three critical dimensions:

Technical Capability Verification

Confirm alignment with core machine specifications: spindle speed (4,000–8,000 RPM for slant-bed models), tool turret capacity (8–12 stations standard), and control system compatibility (Fanuc, Siemens, or GSK). Request documentation on backlash testing, positioning accuracy (±0.01mm typical), and surface finish consistency. For turn-mill compound models, verify live tooling power ratings and C-axis resolution. Prioritize suppliers listing ISO 9001 certification in their compliance profile, indicating standardized quality management systems.

Production Infrastructure Assessment

Evaluate operational scale through verifiable metrics:

- Facility size exceeding 3,000m² to support dedicated machining, assembly, and testing zones

- In-house CNC machining capability for critical components such as bed castings and tailstocks

- Dedicated R&D teams supporting customization (e.g., axis configuration, coolant systems, automation interfaces)

Cross-reference response time data (≤3 hours preferred) and on-time delivery performance (target ≥97%) as indicators of organizational efficiency.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services where release of funds is contingent upon post-arrival inspection. Analyze reorder rates—ranging from 20% to 75% among verified suppliers—as a proxy for customer satisfaction and product reliability. Conduct sample testing focusing on dimensional repeatability, thermal stability during extended operation, and noise levels (should not exceed 75 dB). Require full technical documentation, including wiring diagrams, parameter sheets, and maintenance manuals, prior to shipment.

What Are the Best Mazak CNC Lathe Suppliers?

| Company Name | Location | Verification Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shandong Gsk Cnc Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | CNC Lathes, Slant Bed, Horizontal Bed | 100% | ≤2h | 31% | US $730,000+ | Material, size, logo, color, 5-axis parameters, STL files |

| Foshan Kurui Machinery Co., Ltd. | Guangdong, CN | Multispecialty Supplier | CNC Slant Lathes, Live Tooling Models | 100% | ≤3h | - | - | Material, size, logo, color, packaging |

| Ganzhou Fuxing Intelligent Equipment Co., Ltd. | Jiangxi, CN | General Supplier | CNC Lathes, Machining Centres, Used Equipment | 100% | ≤3h | - | - | Limited |

| Shenzhen Shengmingfa Technology Co., Ltd. | Guangdong, CN | General Supplier | Used CNC Lathes, Turn-Mill Machines | 100% | ≤5h | 20% | US $30,000+ | Limited |

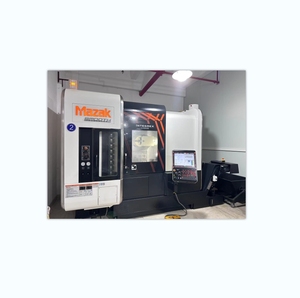

| Ganzhou Fuxing Technology Co., Ltd. | Jiangxi, CN | General Supplier | Used Mazak Models, QT Series, Integrex | 100% | ≤5h | 75% | US $30,000+ | Basic modifications |

Performance Analysis

Shandong Gsk stands out for its robust customization capabilities, high online transaction volume, and rapid response time, making it suitable for buyers requiring tailored configurations and technical documentation. Foshan Kurui offers competitive pricing on new Mazak-style slant-bed lathes with live tooling, supported by strong delivery performance. Among secondary market suppliers, Ganzhou Fuxing Technology demonstrates exceptional customer retention (75% reorder rate), suggesting reliable refurbishment standards for used Mazak equipment such as QT-250L and Integrex I-100S models. While several suppliers list “Mazak” in product titles, most offer functionally similar machines rather than OEM products—clarify origin and branding expectations early in negotiations.

FAQs

Are these authentic Mazak machines or compatible models?

The majority of listings represent CNC lathes designed to emulate Mazak functionality and geometry, often using similar control systems and structural layouts. True OEM Mazak machines are typically sold through authorized dealers and are rarely available on open B2B platforms. Buyers should confirm whether products are original, refurbished, or仿制 (replica-style) units before purchase.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set across all suppliers. Lead times range from 20–30 days for in-stock units to 45–60 days for customized builds, especially those involving special tooling, automation integration, or non-standard bed lengths.

Can suppliers provide CE or ISO certification?

Some suppliers declare ISO 9001 compliance, though formal certification documents should be requested directly. CE marking may be provided upon request, but verification through third-party reports is recommended to ensure conformity with EU machinery directives.

Is customization available for control systems or bed length?

Yes, leading suppliers like Shandong Gsk support customization of CNC controllers (Fanuc, Siemens, GSK), travel distance, spindle bore diameter, and tool count. Technical drawings and STL files are accepted for validation. Prototype builds can be completed within 4–6 weeks for qualified orders.

What shipping options are available for heavy machinery?

Suppliers typically offer FOB terms with loading at major Chinese ports (Qingdao, Shanghai, Shenzhen). Sea freight is standard for full-container loads; air freight is limited to spare parts due to weight and dimension constraints. Buyers are responsible for import clearance, duties, and inland transport unless CIF terms are negotiated.