Mes System In Sap

1/18

1/18

1/27

1/27

CN

CN

1/27

1/27

1/41

1/41

1/22

1/22

CN

CN

1/26

1/26

CN

CN

1/15

1/15

1/31

1/31

About mes system in sap

Where to Find MES System in SAP Suppliers?

The global supply base for MES (Manufacturing Execution Systems) integrated with SAP is highly concentrated in China, where industrial automation hubs in Zhejiang, Hebei, and Guangdong provinces offer specialized expertise. These regions host vertically integrated technology firms that combine software development with hardware integration capabilities, enabling end-to-end deployment of smart manufacturing solutions. Companies in these clusters benefit from proximity to semiconductor suppliers, R&D talent pools, and government-backed industrial digitization initiatives, reducing implementation timelines by up to 30% compared to decentralized vendors.

Suppliers typically operate hybrid production models—developing proprietary software modules while outsourcing server infrastructure or edge devices. This allows scalable delivery of turnkey MES-SAP systems tailored to discrete, process, and hybrid manufacturing environments. Buyers gain access to mature ecosystems featuring modular architectures, pre-built SAP interface connectors, and cloud/on-premise deployment flexibility. Key advantages include reduced integration complexity, predictable project timelines (average 60–90 days for full rollout), and cost efficiency driven by competitive pricing and localized engineering support.

How to Choose MES System in SAP Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Integration Capability

Verify proven experience in SAP ERP integration, particularly with SAP S/4HANA, ECC, and PP/PI modules. Demand documented case studies showing real-time data synchronization between shop floor operations and SAP backend systems. Confirm support for industry-standard communication protocols such as OPC UA, MQTT, and BAPI/RFC interfaces.

Software Development & Quality Assurance

Evaluate the supplier’s development lifecycle:

- Use of agile or DevOps methodologies with version control systems

- In-house QA teams conducting unit, integration, and stress testing

- Compliance with ISO 27001 (information security) and IEC 62443 (industrial network security)

Cross-reference system uptime records (>99.5%) and mean time to repair (MTTR < 2 hours) to assess reliability.

Project Implementation & After-Sales Support

Require structured deployment frameworks including gap analysis, blueprint design, sandbox testing, and user training. Analyze supplier track records through verifiable client references, focusing on post-go-live support responsiveness and bug resolution speed. Onsite commissioning and remote monitoring should be standard service offerings.

What Are the Best MES System in SAP Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|

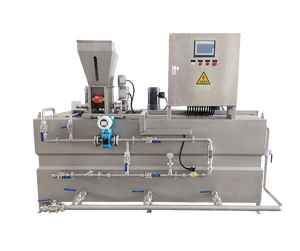

| Benlong Automation Technology Co., Ltd. | MES Intelligent Manufacturing Process Execution System | $11,500–98,000 | 1 set | 100% | ≤4h | - | Yes |

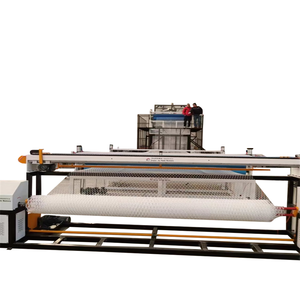

| Hebei Rongkuai Machinery Manufacturing Co., Ltd. | Energy-Saving Wire Mesh Welding System | $4,000–12,800 | 1–2 sets | 100% | ≤4h | - | Limited |

| Anping Tailun Wire Mesh Products Co., Ltd. | Stainless Steel Security Mesh | $7.50–9.90/sqm | 10 sqm | 85% | ≤8h | 16% | No |

| Anping Junao Wire Mesh Products Co., Ltd. | Welded Mesh Machine Automation | $9,222–23,554 | 1 set | 100% | ≤5h | - | Partial |

| Shenzhen First Tech Co., Ltd. | BESS Energy Storage Systems | $119,999–359,999 | 1 set | 100% | ≤1h | <15% | Yes |

Performance Analysis

Benlong Automation Technology stands out with a comprehensive portfolio of SAP-integrated MES solutions spanning $11,500 to $98,000, indicating scalability for both mid-tier and large manufacturers. The company’s 100% on-time delivery rate and ≤4-hour response time reflect strong operational discipline. Shenzhen First Tech demonstrates premium positioning with high-value system pricing, ultra-fast response times (≤1h), and customization options across energy storage parameters—suggesting advanced project management infrastructure despite lower reorder rates. In contrast, wire mesh machinery suppliers like Hebei Rongkuai and Anping Junao list "MES system, SAP" as keywords but primarily offer industrial equipment without dedicated software integration evidence, representing potential mismatches for pure digital transformation buyers.

FAQs

How to verify MES system supplier reliability?

Cross-check technical documentation, including system architecture diagrams, API specifications, and SAP integration certificates. Request proof of completed implementations with anonymized client reports detailing ROI metrics such as OEE improvement, scrap reduction, and labor efficiency gains. Validate cybersecurity practices through third-party audit summaries or penetration test results.

What is the typical implementation timeline?

Standard MES-SAP deployments require 60–90 days, broken into phases: requirement gathering (10–15 days), system configuration (20–30 days), testing and validation (15–20 days), and go-live with training (10–15 days). Complex multi-site rollouts may extend to 120 days depending on legacy system compatibility.

Can suppliers provide customized MES modules?

Yes, leading suppliers offer configurable modules for production tracking, quality management, maintenance scheduling, and performance analytics. Custom development is available for unique workflows, provided specifications are submitted in IDEF0 or BPMN format. Turnaround for custom module delivery averages 4–6 weeks post-approval.

What are common MOQ and payment terms?

Minimum order quantity is typically one system license or deployment instance. Payment structures often follow milestone-based schedules: 30% advance, 40% upon completion of configuration, and 30% after successful commissioning. Escrow services are recommended for transactions exceeding $50,000.

Do suppliers support international installations?

Yes, experienced vendors manage global deployments with multilingual UI support, local regulatory compliance (e.g., GDPR, NIST), and regional data hosting options. Onsite engineers can be dispatched for installation and training, with travel costs billed separately. Remote support remains active post-deployment via secure VPN connections.